Method for circularly processing and utilizing rhizome in dioscorea

A technology of cyclic processing and yam root, applied in the direction of steroids and organic chemistry, can solve the problems of incomplete destruction of starch and saponin yam root stem cell wall, large investment in equipment, waste of resources, etc., so as to improve the utilization value and reduce the The number of times of acid hydrolysis and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

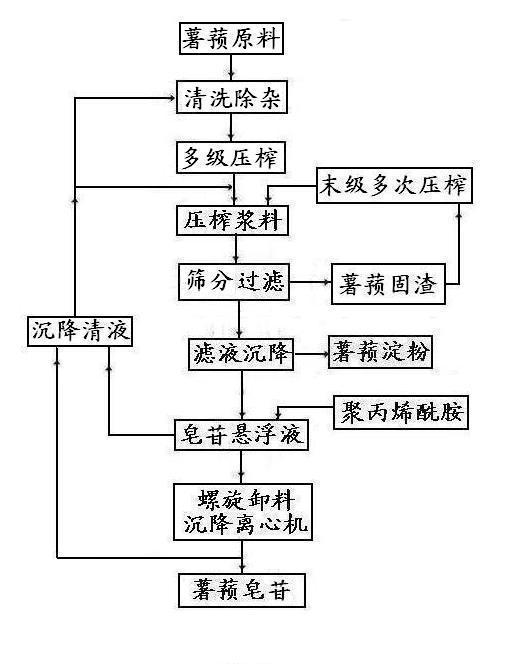

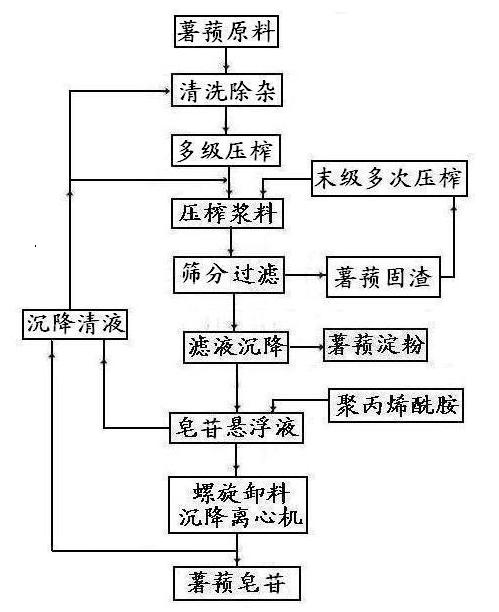

Image

Examples

Embodiment

[0038] A set of metal press rollers is used as the pressing equipment:

[0039] ① Wash 1500 grams of fresh turmeric with fresh water to remove impurities.

[0040] ② Adjust the roller spacing of the metal pressing roller to 2-3mm, start the motor, and add 1500 grams of fresh turmeric for pressing.

[0041] ③Adjust the roller spacing of metal press rollers to 0.3-1mm and 0.05-0.1mm respectively, and press once.

[0042] ④ Adjust the roller spacing of the metal press rollers to less than 5 microns, and press three times.

[0043] ⑤ Add the squeezed material into a container filled with 7500 grams of fresh water to make a slurry, and stir for 2 minutes.

[0044] ⑥ Filter the slurry of ⑤ through a stainless steel filter sieve with a pore size of 75 microns, and wash the filter residue once with the upper filtrate clear night.

[0045] ⑦Filter the filter residue of ⑥ with a filter cloth once, press out a large amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com