Plastic filling agent and preparation method thereof

A technology for plastic fillers and particles, applied in the field of plastic fillers and their preparation, can solve the problems of harsh technical conditions, long process, failure of coupling agent synthesis, etc., to overcome van der Waals force, short process and modification effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

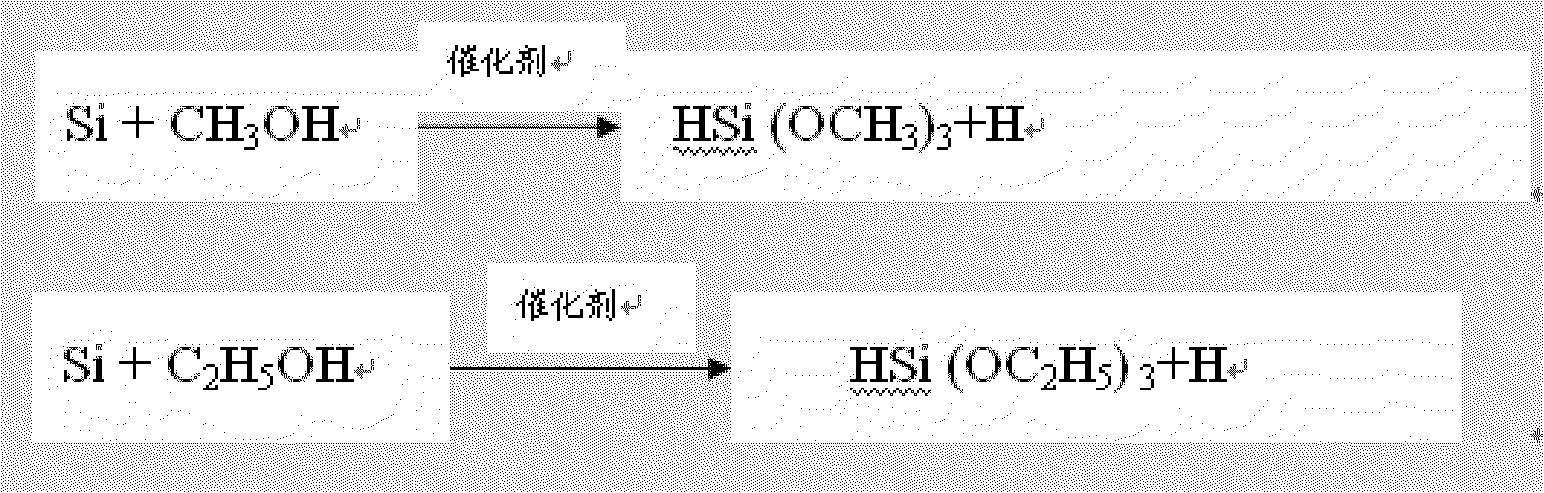

Method used

Image

Examples

Embodiment 1

[0031] The plastic filler of the present embodiment is a mixture of calcium carbonate particles and copper compounds coated with trimethoxysilane on the surface, the mass percentage of calcium carbonate particles in the mixture is 99%, and the mass percent of trimethoxysilane The percentage content is 0.9%, and the balance is copper chloride.

[0032] The particle size of the calcium carbonate particles in the plastic filler of this embodiment is 0.1-20 μm.

[0033] The preparation method of the plastic filler of the present embodiment, comprises the following steps:

[0034] (1), 9.9kg anhydrous calcium carbonate, 99g metal silicon, 9.9g copper chloride are added in the dry ball mill, the quality of added metal silicon is 1% of anhydrous calcium carbonate quality, the quality of added copper chloride 0.1% of the mass of anhydrous calcium carbonate;

[0035] (2), grind the mixture added in step (1) at a temperature of 200°C-350°C, add industrial methanol to the ball mill at ...

Embodiment 2

[0037]The plastic filler of the present embodiment is a mixture of calcium carbonate particles and copper oxide coated with triethoxysilane on the surface, the mass percentage of calcium carbonate particles in the mixture is 90%, and the content of triethoxysilane The mass percentage is 9.5%, and the balance is copper oxide.

[0038] The particle size of the calcium carbonate particles in the plastic filler is 0.1-20 μm.

[0039] The preparation method of the plastic filler of the present embodiment, comprises the following steps:

[0040] (1), 9.9kg anhydrous calcium carbonate, 990g metal silicon, 49.5g copper oxide are added in the Raymond ball mill, the quality of added metal silicon is 10% of anhydrous calcium carbonate quality, the quality of added copper oxide is 0.5% of the mass of anhydrous calcium carbonate;

[0041] (2), grind the mixture added in step (1) at a temperature of 200°C-350°C, add technical grade ethanol to the ball mill at a flow rate of 2mg-50mg / min d...

Embodiment 3

[0047] The plastic filler of the present embodiment is a mixture composed of calcium carbonate particles and copper hydroxide coated with trimethoxysilane and triethoxysilane on the surface, and the mass percentage of calcium carbonate particles in the mixture is 95%. , the mass percent content of trimethoxysilane and triethoxysilane is 2%, and the balance is copper hydroxide.

[0048] The particle size of the calcium carbonate particles in the plastic filler is 0.1-20 μm.

[0049] The preparation method of the plastic filler of the present embodiment, comprises the following steps:

[0050] (1), 9.9kg anhydrous calcium carbonate, 198g metal silicon, 49.5g copper hydroxide are added in the wind mill, the quality of added metal silicon is 2% of anhydrous calcium carbonate quality, the quality of added copper hydroxide 0.5% of the mass of anhydrous calcium carbonate;

[0051] (2), grind the mixture added in step (1) at a temperature of 200°C-350°C, add industrial methanol and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com