Heat-preservation cylinder for single crystal furnace and single crystal furnace with same

A heat preservation cylinder and single crystal furnace technology, which is applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of heat waste and low heat reflectivity of heat preservation cylinder materials, so as to reduce production costs and solve heat waste , The effect of reducing thermal power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

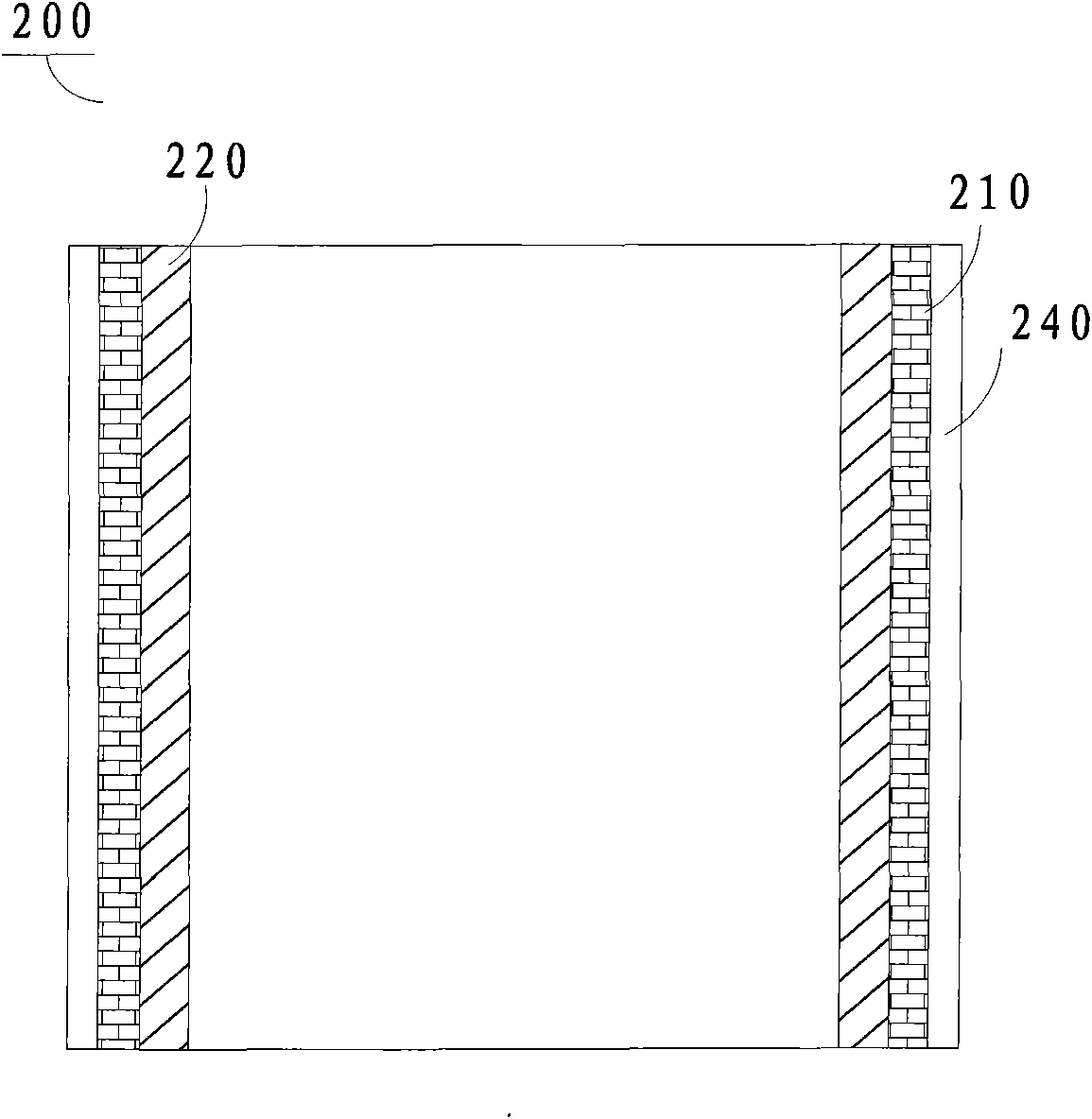

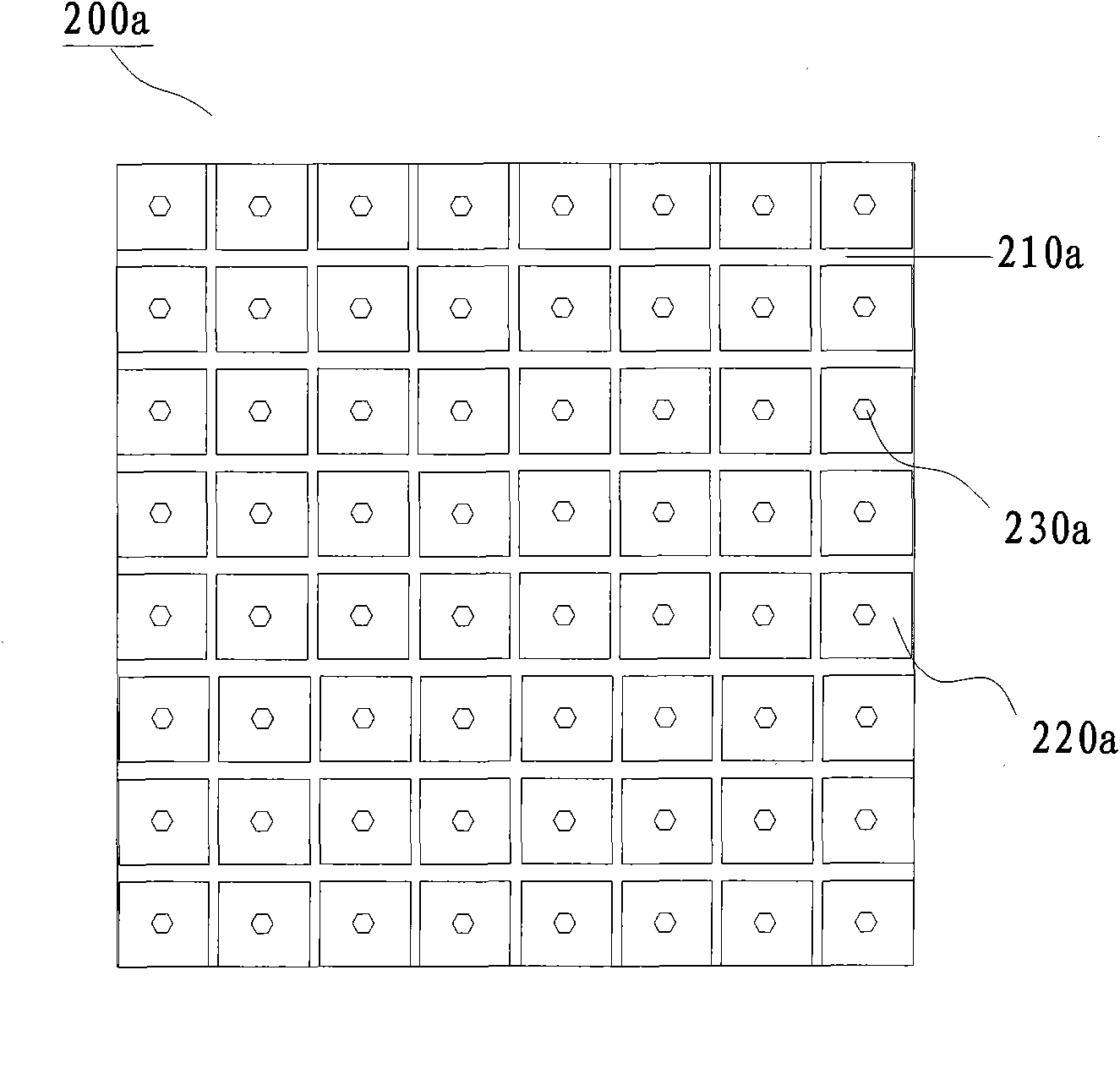

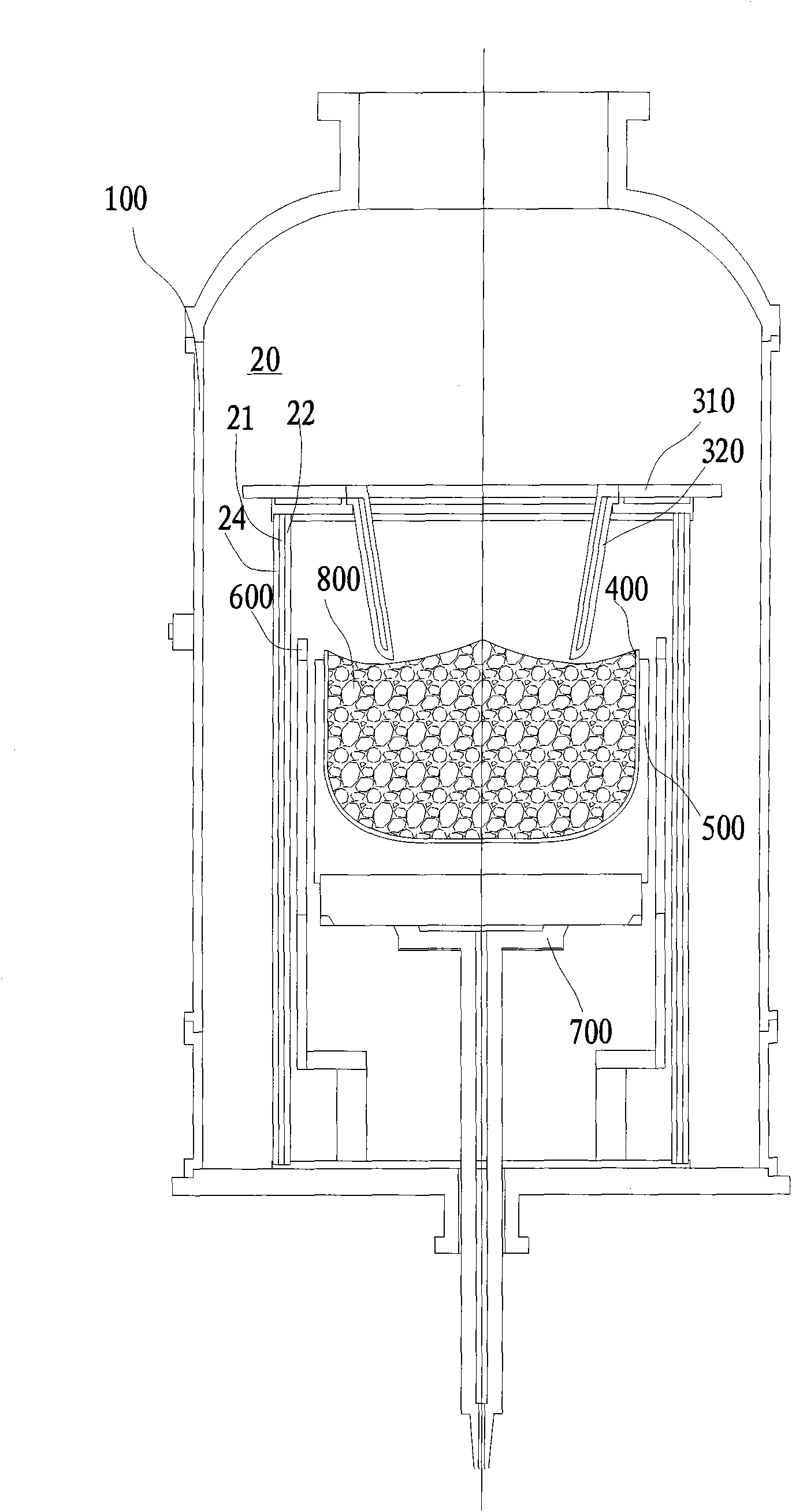

[0021] The insulation cylinder usually used for single crystal furnace is composed of carbon felt material or carbon fiber insulation layer and graphite material support layer, and the insulation layer can be located inside or outside the support layer; The first layer is the insulation layer and the outer layer is the insulation cylinder of the support layer. In addition, there is a thermal insulation cylinder that integrates graphite material and thermal insulation material. For the sake of simplicity, in the present invention, the layers located inside the thermal insulation cylinder in the above-mentioned structure are collectively referred to as "inner layers", and the layers located on the outside are collectively referred to as "outer layers". In the case of a cartridge, it is also referred to as an "inner layer". It should be noted that the present invention can be applied no matter in the structure in which the thermal insulation layer is located on the inside or out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com