Construction method of suspension type template support in high-position conjoined structure

A conjoined structure and formwork support technology, which is applied in the direction of building construction, construction, and building material processing, can solve problems such as unsatisfactory construction methods, and achieve the effects of ensuring the safety of high-altitude operations, saving construction costs, and increasing the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

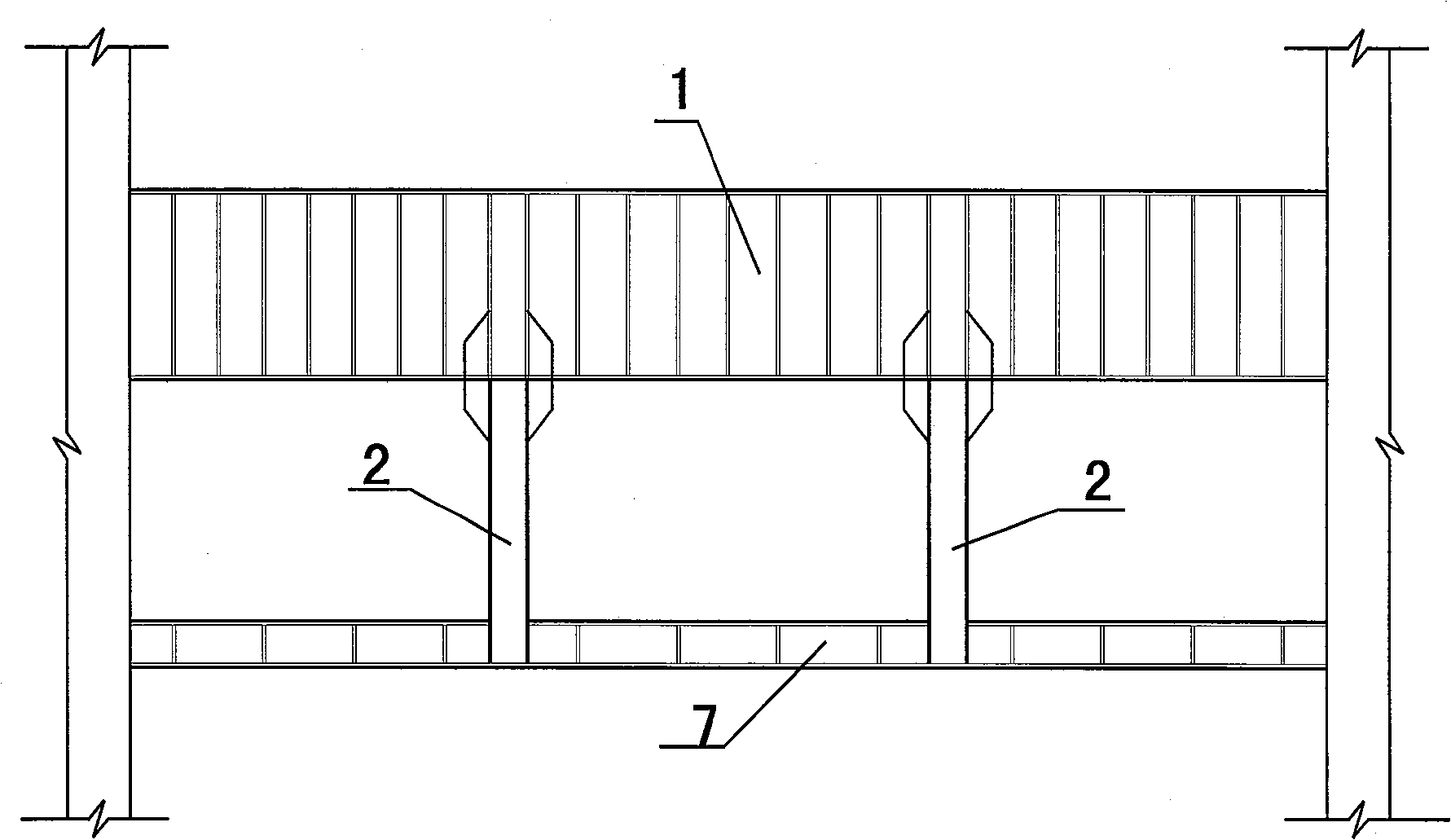

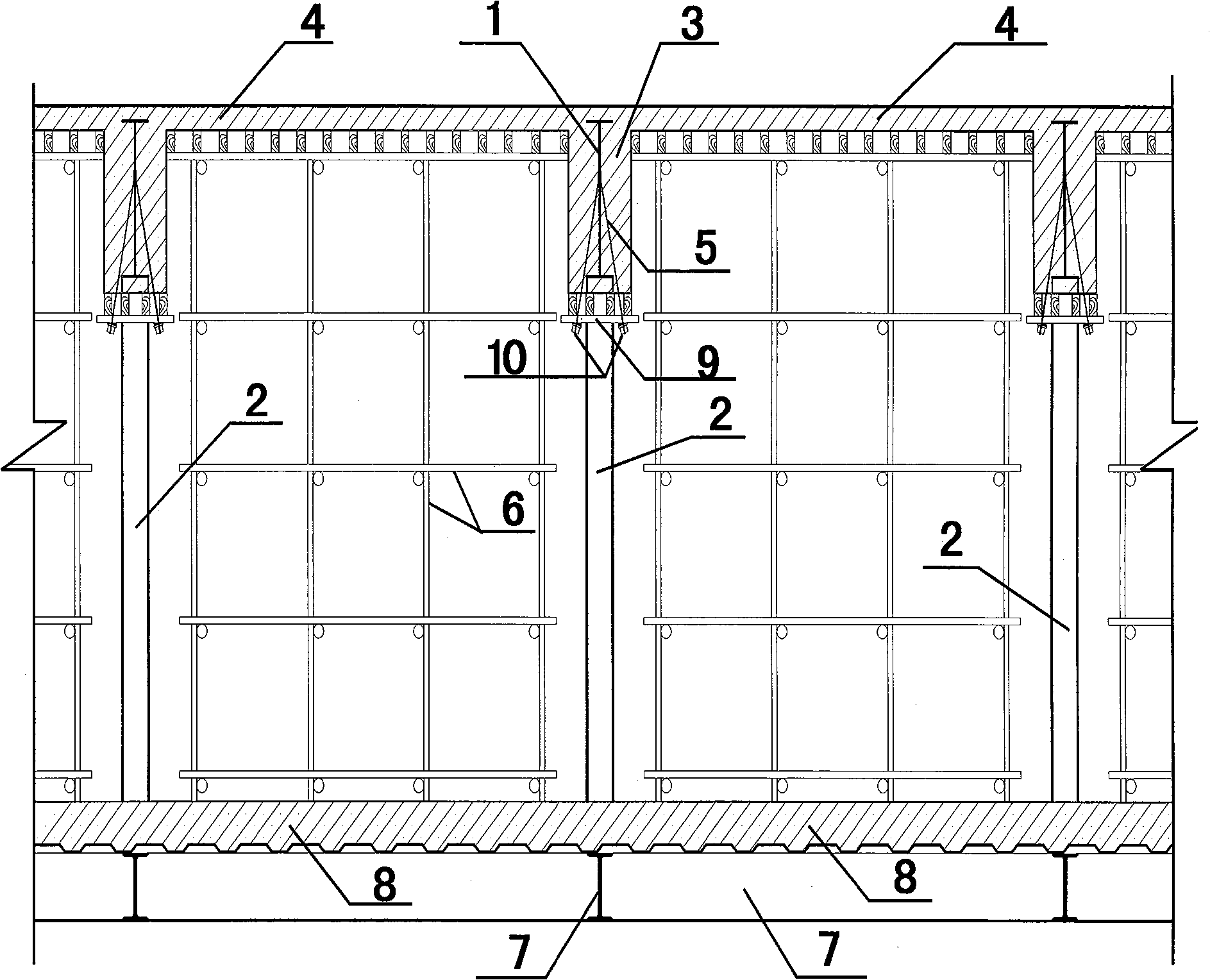

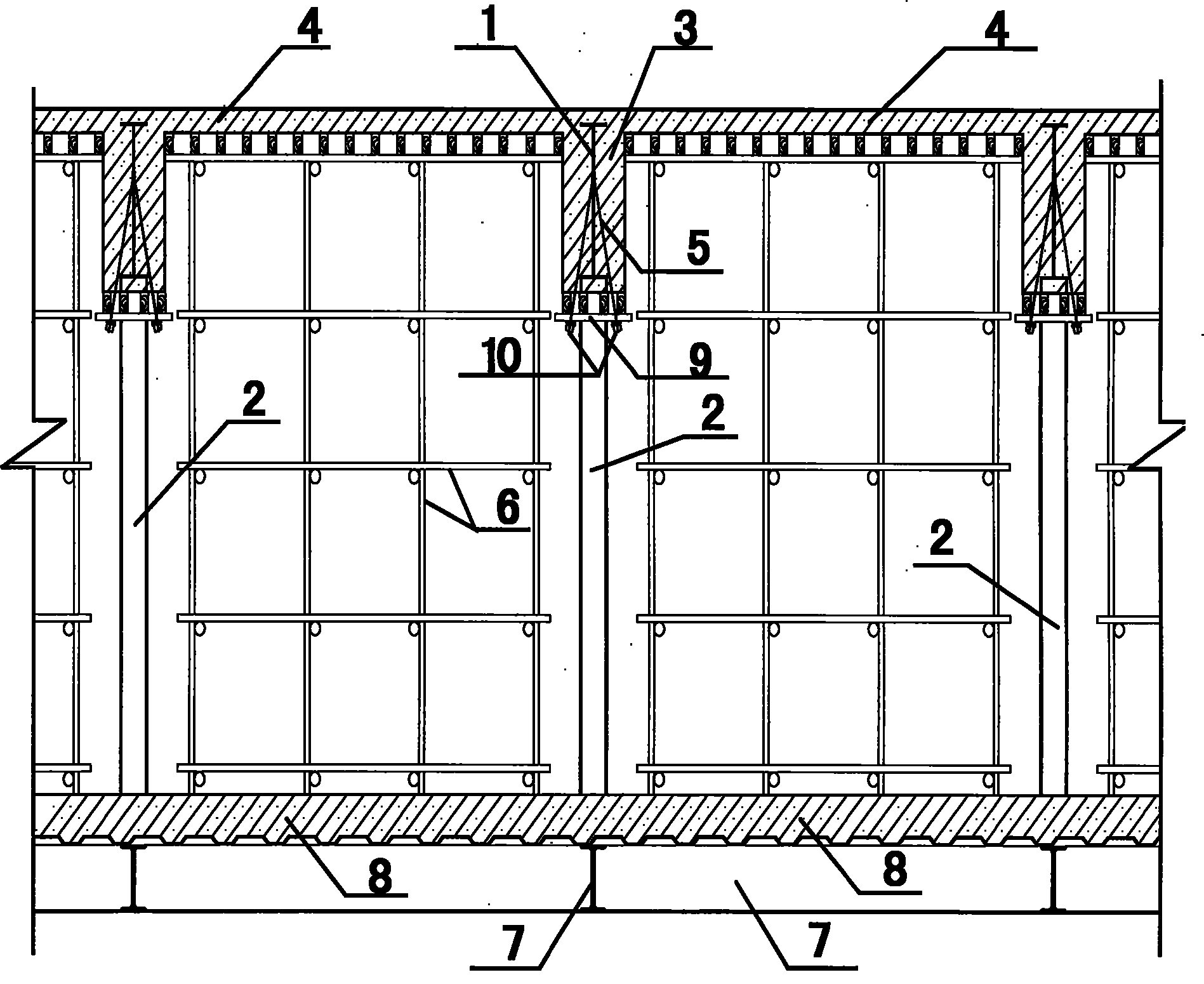

[0027] Such as figure 1 , figure 2 Shown:

[0028] The steel-reinforced concrete conjoined transfer layer suspended formwork support system consists of two parts:

[0029] 1) Steel-reinforced concrete conjoined transfer beam 3 (consisting of steel main beam 1 and concrete) adopts self-supporting formwork (consisting of steel main beam 1, steel tie rod 5, channel steel 9 and straight thread sleeve 10), the concrete, The weight of steel bar and formwork and construction live load are transferred to steel girder 1 through multiple pairs of evenly distributed steel tie rods 5;

[0030] 2) The concrete floor 4 of the transfer floor adopts the conventional floor formwork support 6, and the steel structure refuge floor 7 suspended by several steel suspenders 2 from the lower part of the transfer floor bears various loads of the floor formwork support 6.

[0031] 1. A conjoined load-bearing structure is composed of a steel-reinforced concrete conjoined transfer layer and a suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com