Vacuum pump without pressure difference

A vacuum pump and differential pressure technology, which is applied in the field of vacuum pumps, can solve the problems of increased motor power loss, increased pump body load, and noise pollution in the surrounding environment, achieving the effects of reducing power loss, isolating mechanical noise, and prolonging the life of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

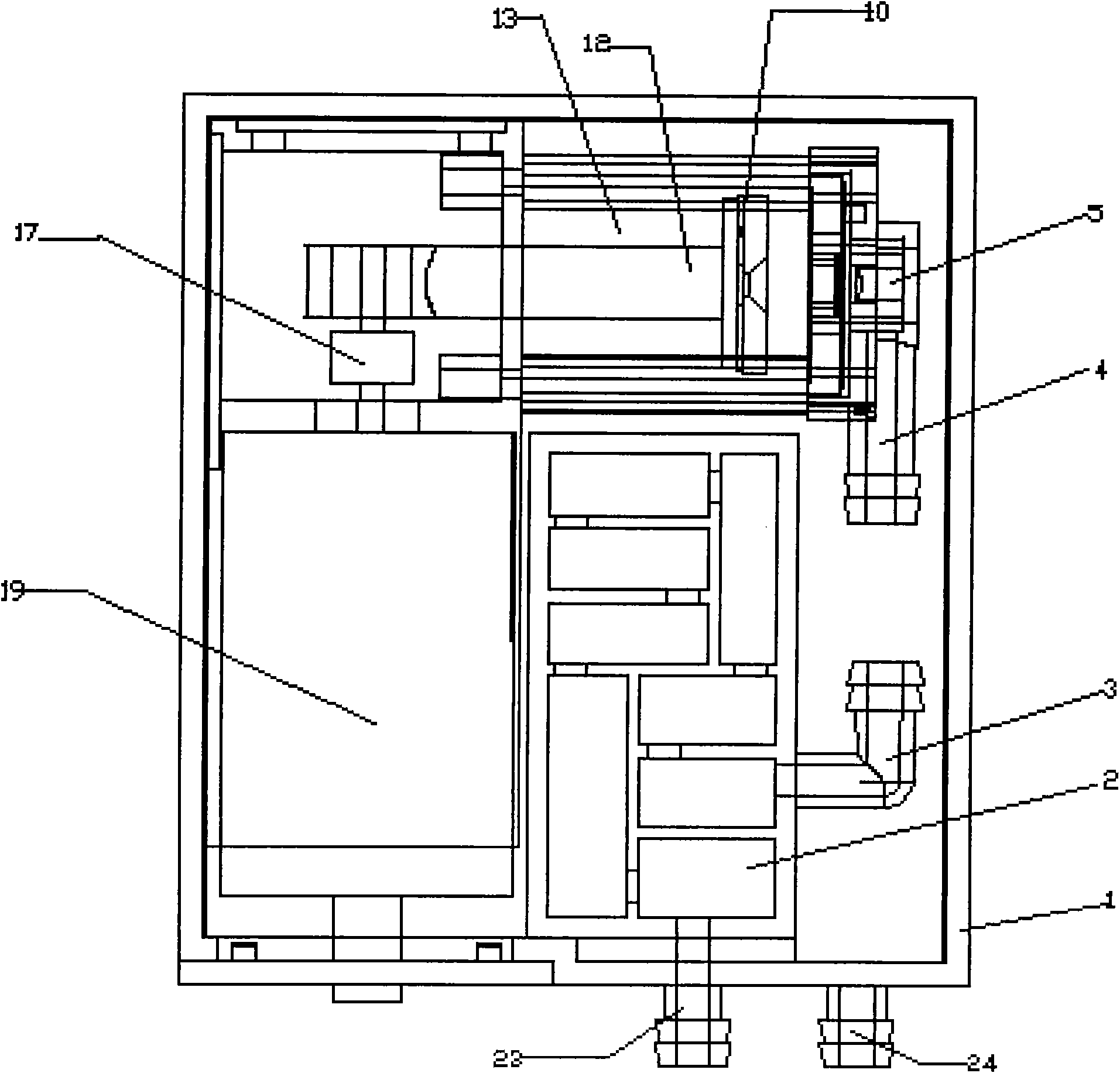

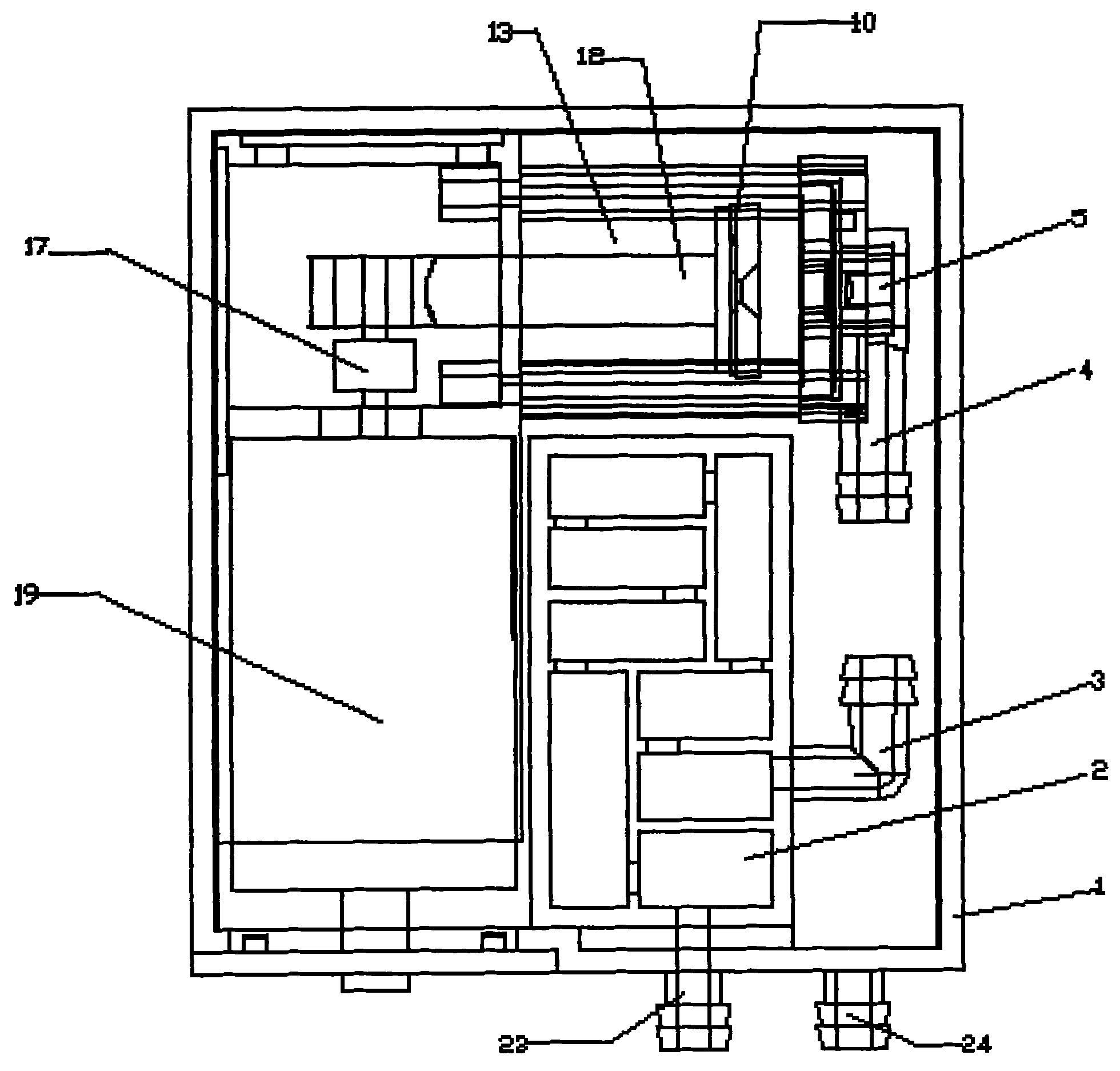

[0014] Such as figure 1 As shown, the pressure-free vacuum pump includes a vacuum pump main body, the vacuum pump main body is a slide valve pump, which includes a motor 19, a cylinder 13 and a piston 10, the piston 10 is located in the cylinder 13, and one end of the piston 10 is provided with a connecting rod 12 , the output shaft of the motor 19 is connected with the connecting rod 12 through an eccentric wheel 17 . The motor 19 drives the piston 10 to reciprocate in the cylinder 13 through the eccentric wheel 17, so that the volume in the cylinder changes to realize outward air extraction. The cylinder 13 is provided with a vacuum pump exhaust hole 5 and a vacuum pump exhaust hole 4 . The main body of the vacuum pump is sealed in a housing 1. The housing 1 is provided with an air inlet 24 and an air outlet 23. The housing 1 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com