Method for determining volatile flavor substance of egg yolk

A technology of volatile substances and flavor substances, which is applied in the field of determination of volatile flavor substances of egg yolk, and can solve problems such as non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

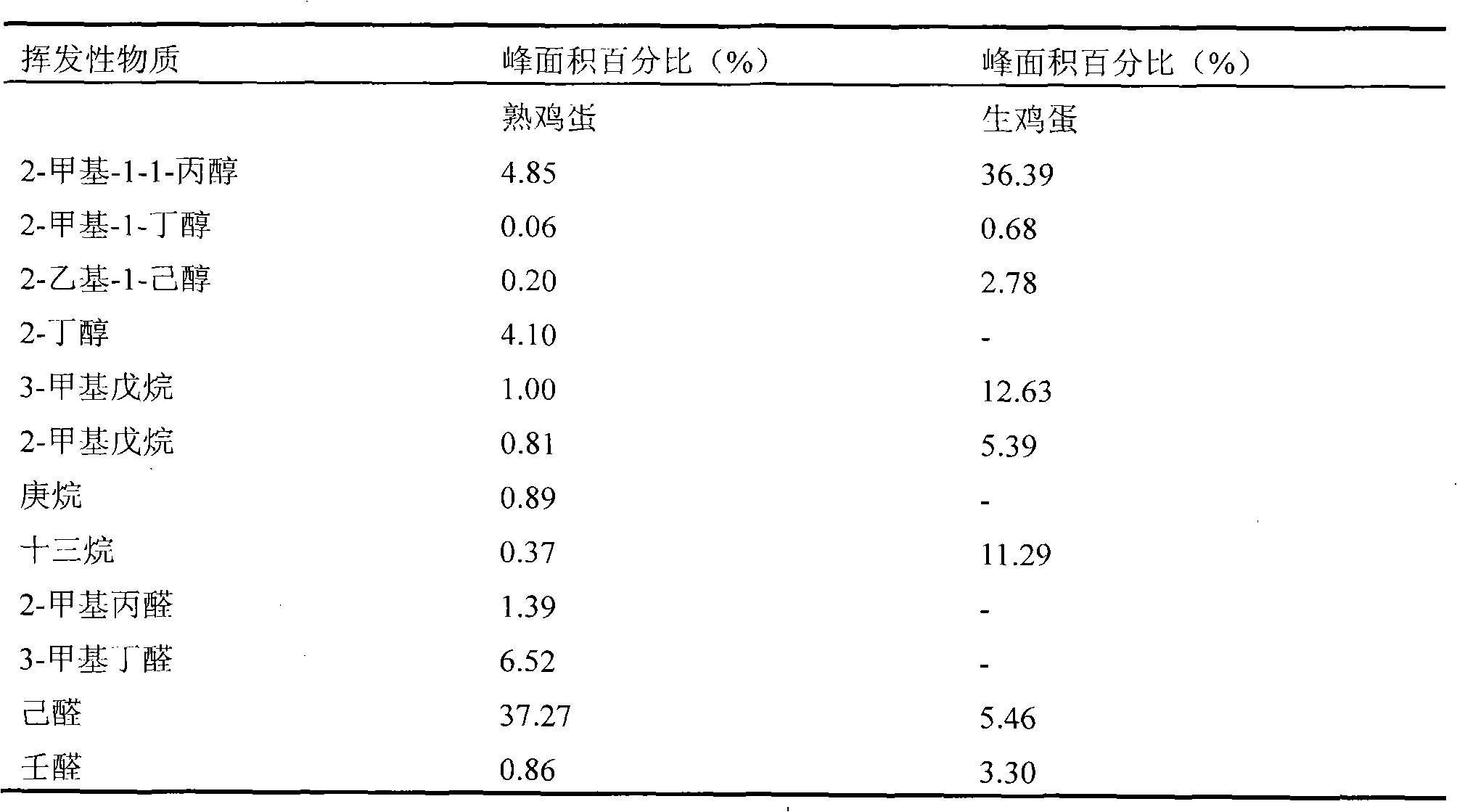

[0024] Crack the shell of a raw egg, carefully separate the yolk, then gently roll the yolk on a piece of absorbent paper to remove the egg white on the surface. Put the egg yolk in the flask and mix well with a glass rod. Then put a magnetic rotor in the flask, heat it in a water bath to 45°C, use a glass adsorption tube (15cm×0.3cmID) equipped with 0.14g TenaxTA to dynamically capture volatile substances, absorb for 30min, and then remove the TA tube. Backflush with high-purity nitrogen for 30 minutes (10ml / min). Then set the working conditions of GC-MS as follows: TCT system pressure 20kPa; inlet temperature 260°C; cold trap temperature -120°C; . The temperature was programmed to rise to 40°C and held for 3 minutes, then raised to 270°C at a rate of 6°C / min and held for 3 minutes, and the post-column temperature was raised to 280°C and held for 5 minutes. The EI source of MS is 70eV; its mass range is 19-420amu, the interface temperature is 250°C, the source temperature ...

Embodiment 2

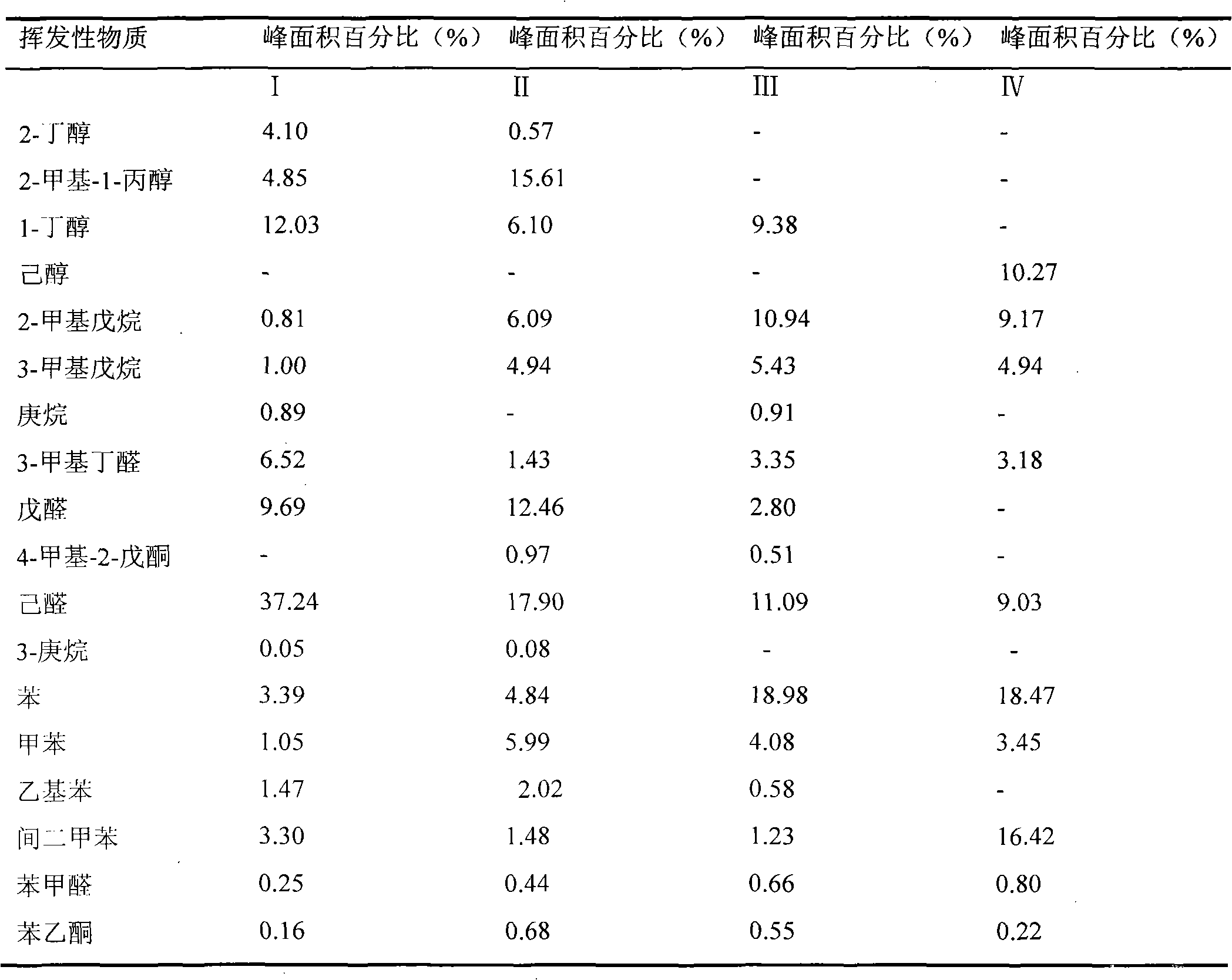

[0026] Boil the eggs in boiling water at 100°C for 15 minutes, take them out, let them cool, break them, take out the egg yolks, put the two egg yolks into a flask, grind them, heat the sample to 65°C for adsorption, and heat in a water bath without adding a rotor At 45°C, use a glass adsorption tube (15cm×0.3cmID) equipped with 0.14gTenax TA to dynamically trap volatile substances, absorb for 45min, then remove the TA tube, and backflush with high-purity nitrogen for 30min (10ml / min). The working conditions of GC-MS were set as follows: TCT system pressure 20kPa; inlet temperature 260°C; cold trap temperature -120°C; pre-cooling 5min desorption temperature 250°C (10min), cold trap injection temperature 260°C. The temperature was programmed to rise to 40°C and held for 3 minutes, then raised to 270°C at a rate of 5°C / min and held for 3 minutes, and the post-column temperature was raised to 280°C and held for 5 minutes. The EI source of MS is 70eV; its mass range is 19-420amu, ...

Embodiment 3

[0028]Boil the eggs in boiling water at 100°C for 20 minutes, take them out, let them cool, break them, take out the egg yolks, put the two egg yolks in a group into a flask, grind them, heat the sample to 65°C for adsorption, and heat in a water bath without adding a rotor At 50°C, use a glass adsorption tube (15cm×0.3cmID) equipped with 0.14gTenax TA to dynamically trap volatile substances, absorb for 30min, then remove the TA tube, and backflush with high-purity nitrogen for 60min (10ml / min). The working conditions of GC-MS are set as follows: TCT system pressure 20kPa; inlet temperature 260°C; cold trap temperature -120°C; The temperature was programmed to rise to 40°C and held for 3 minutes, then raised to 270°C at a rate of 6°C / min and held for 3 minutes, and the post-column temperature was raised to 280°C and held for 5 minutes. The EI source of MS is 70eV; its mass range is 19-420amu, the interface temperature is 250°C, the source temperature is 200°C, and the filament...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com