Broadband all-dielectric multilayer-film reflective diffraction grating and design method thereof

A reflection-diffraction, all-dielectric technology, applied in the field of gratings, can solve problems such as limiting the ability of gratings to resist laser damage and destroying beam wavefronts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

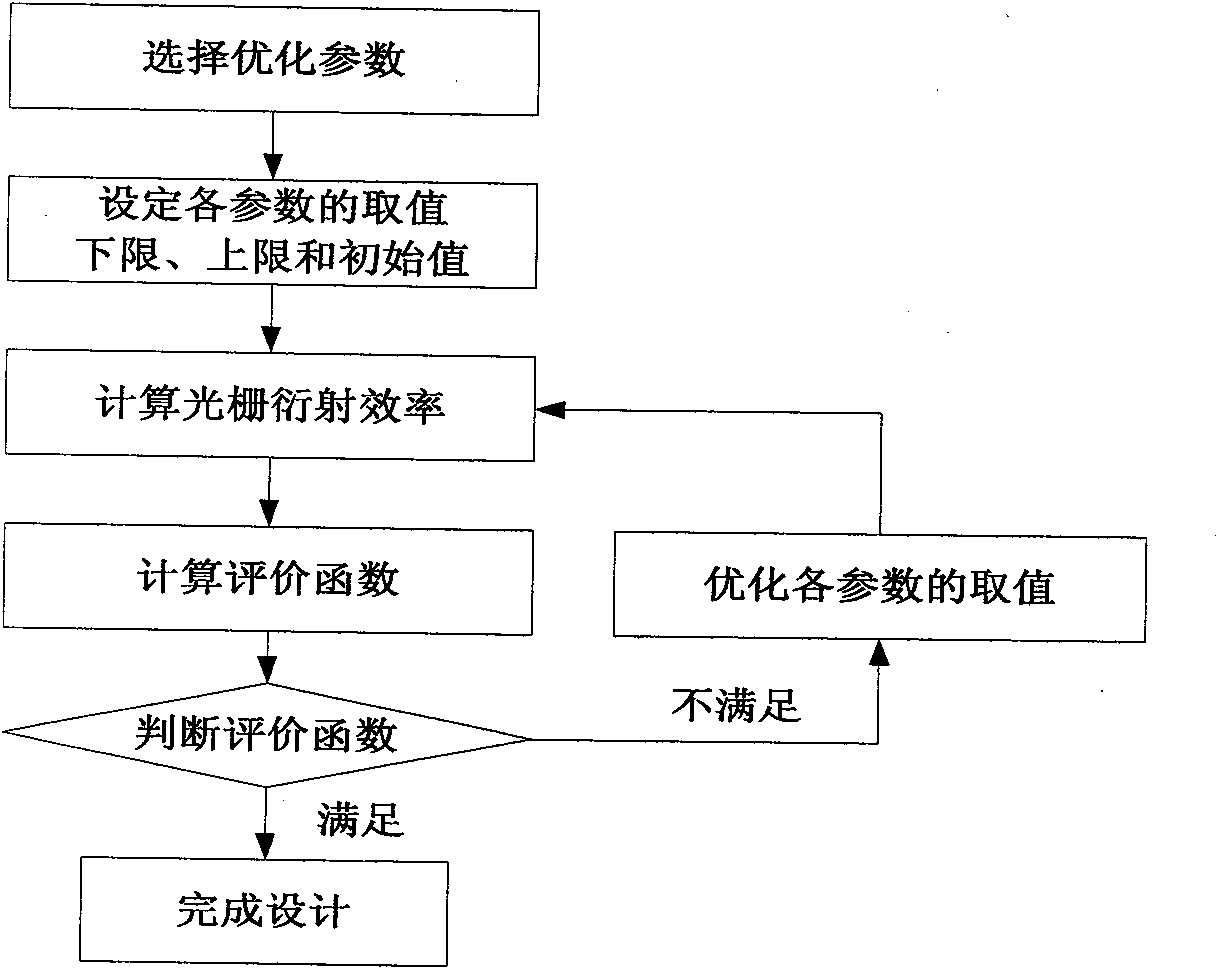

Method used

Image

Examples

example 1

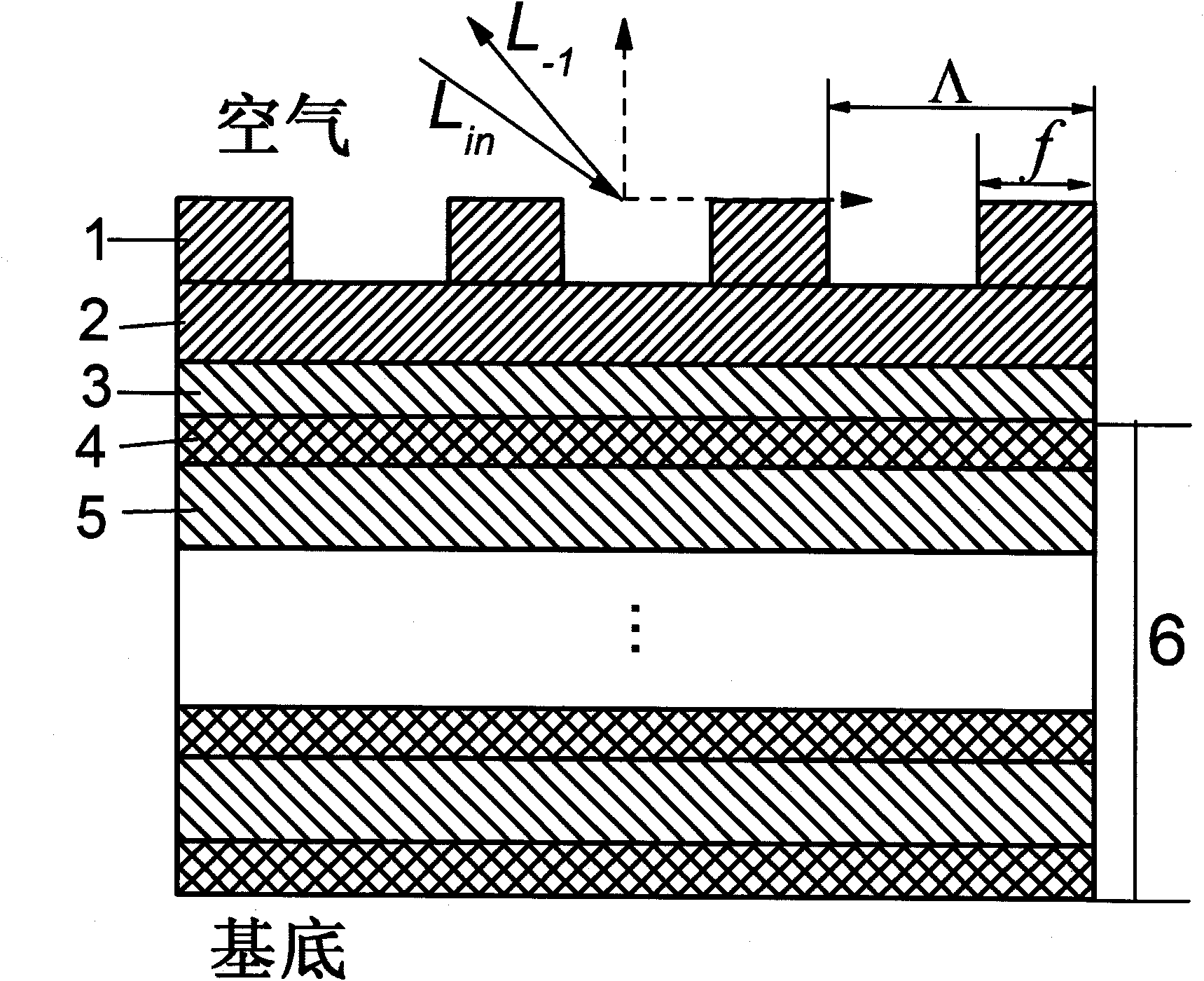

[0086] The grating uses an angle of 57 degrees. The structure of the multilayer dielectric film used for the broadband all-dielectric multilayer film reflection diffraction grating of the present invention is: S(HL) 9 H M R G A. H and L are the high-refractive index material film layer and the low-refractive index material film layer with the thickness of a quarter of the reference wavelength, respectively, and the HL basic film system is repeated 9 times; M is the matching layer, and G and R are the top-layer etched grating structure layer and the top layer etch the remaining film layers. S is the K9 substrate, and A is the incident air layer. The materials and corresponding refractive indices of each layer are as follows:

[0087]

[0088] In this example, the grating period ranges from 480nm to 510nm. The duty cycle ranges from 0.25 to 0.5. The upper and lower limits of grating etching thickness, top layer remaining thickness and matching layer thickness are 300nm,...

example 2

[0095] The grating structure and usage conditions are the same as those in Design Example 1, and the Ta in Design Example 1 2 o 5 Replaced with TiO 2 (refractive index 2.31), other materials remain unchanged. When optimizing the design, the value range of each parameter and the optimization steps are also consistent with the design example one. After multiple optimizations and designs, the minimum rating function value is 1.4358, the corresponding grating period is 510nm, and the duty ratio is 0.25. The etching thickness of the grating, the remaining thickness of the top layer and the thickness of the matching layer are 210nm, 11nm and 18nm, respectively. The reference wavelength is 834nm.

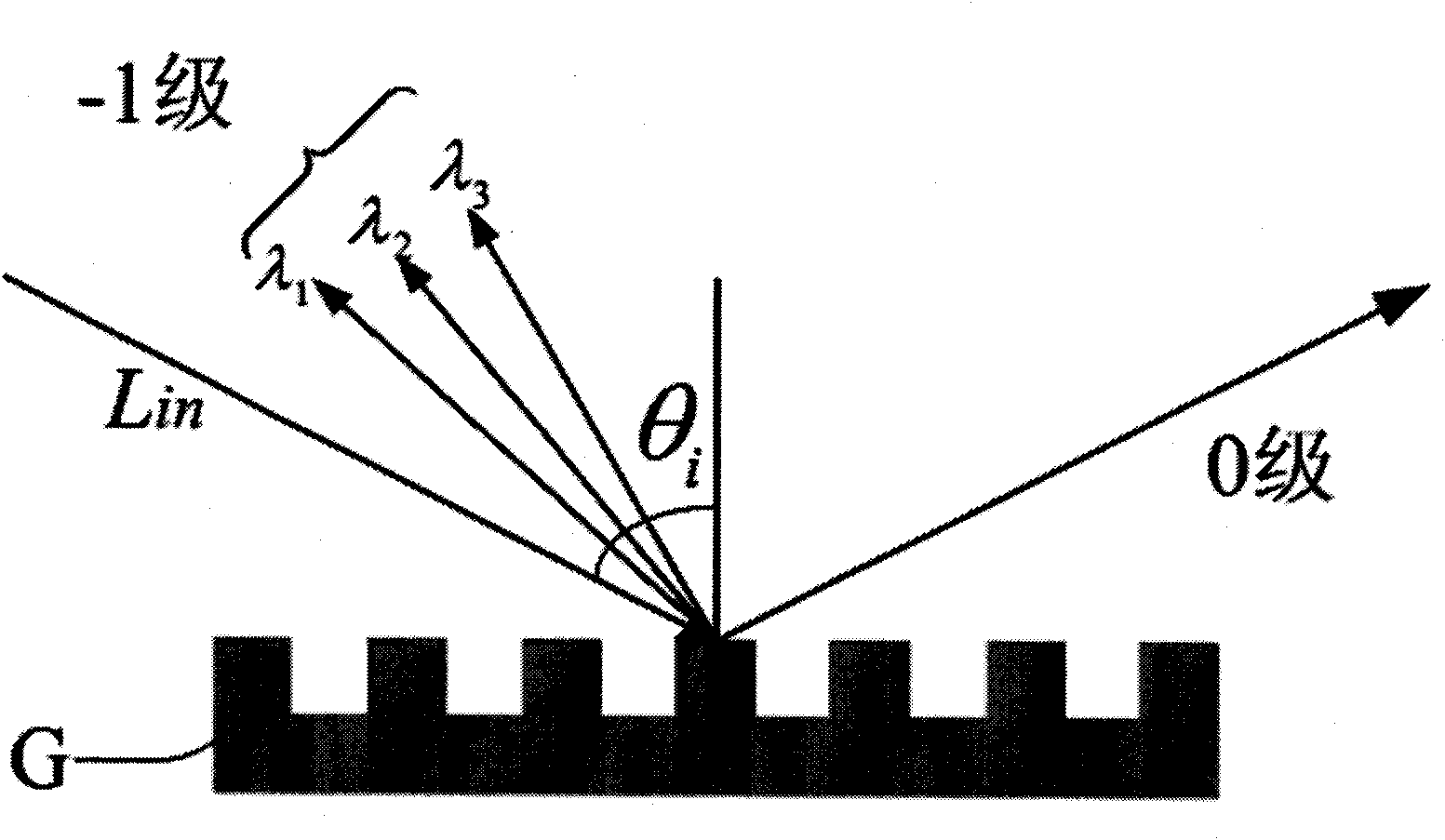

[0096] Figure 4 It is the broadband diffraction spectrum of the broadband all-dielectric multilayer reflection diffraction grating of the present invention. With 800nm as the center wavelength, the diffraction efficiency of the grating exceeds 98% and the bandwidth exceeds 100nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com