Ultra-pure self-adaptive nonlinear control system and method for internal thermally coupled distillation column

An internal thermal coupling, nonlinear control technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as poor interference suppression ability and poor control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

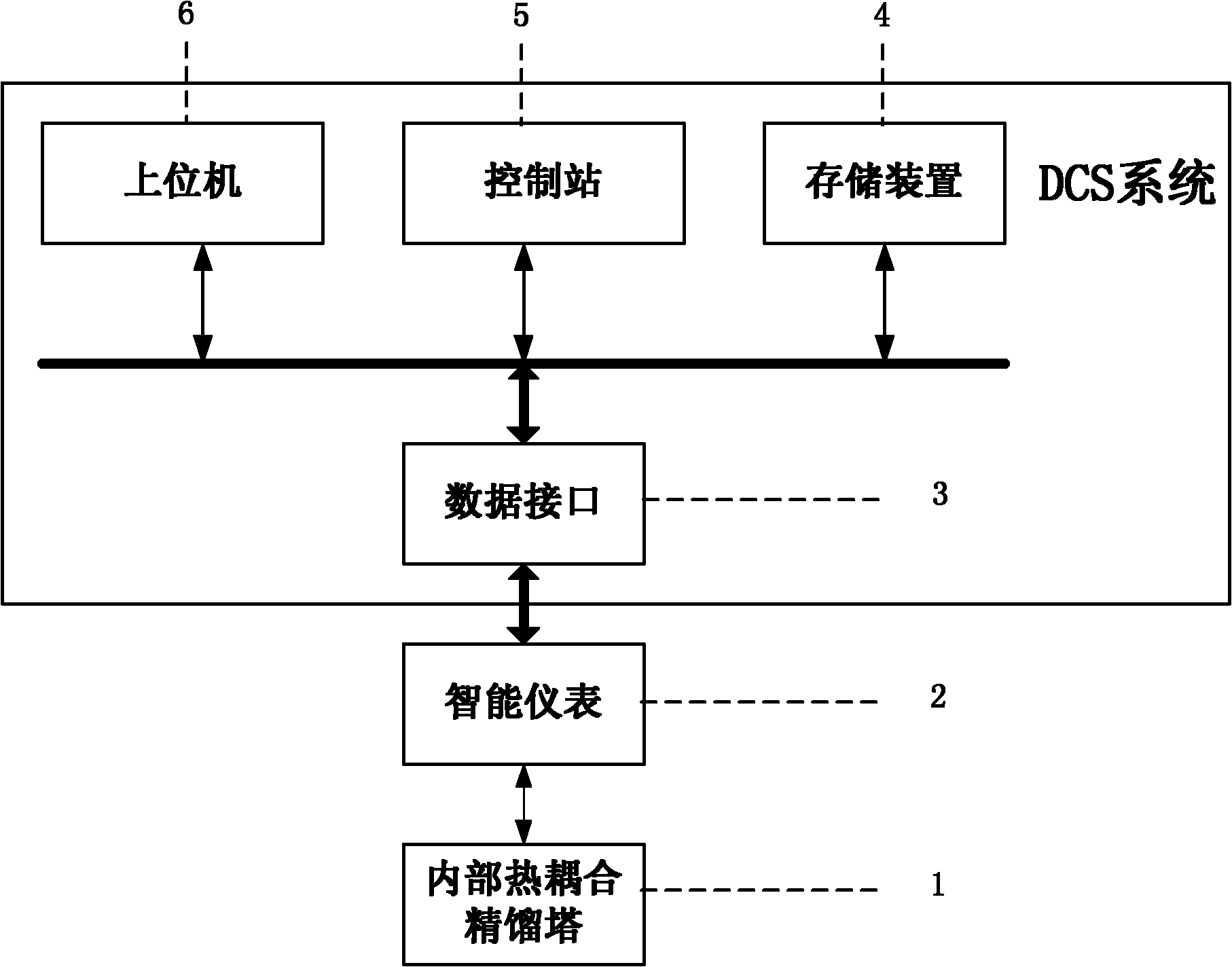

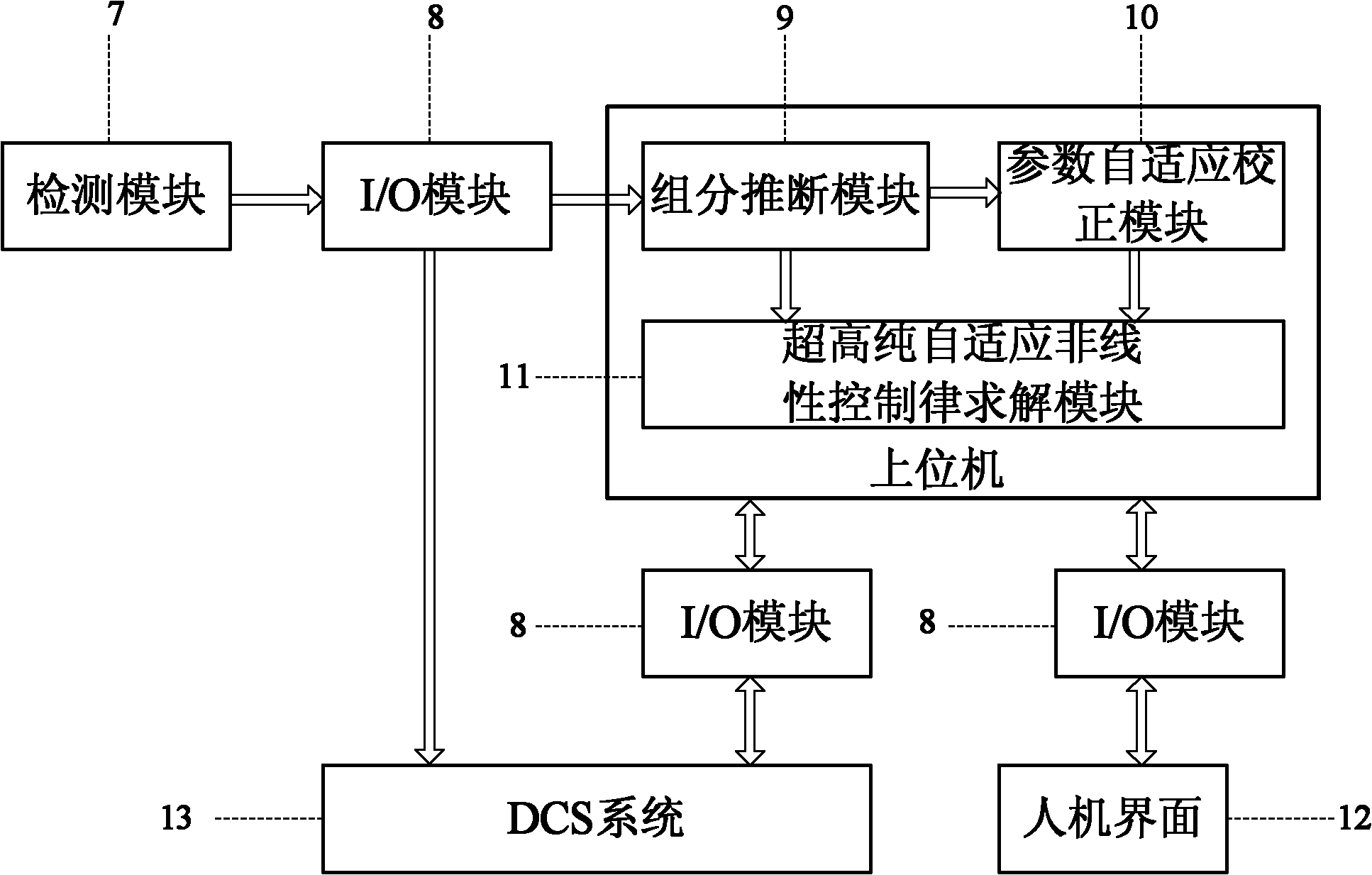

[0074] refer to figure 1 , figure 2 , an internal heat-coupled rectification tower ultra-high-purity self-adaptive nonlinear control system, the control system includes field intelligent instruments 2 and a DCS system directly connected to the internal heat-coupled rectification tower, and the DCS system includes a storage device 4, a control Station 5 and host computer 6, wherein the on-site intelligent instrument is connected with the storage device 4, the control station 5 and the host computer 6 through the field bus and the data interface 3; the intelligent instrument is used to realize the function of the detection module 7, that is, to detect the internal The temperature and pressure data of the thermally coupled rectification tower, the data interface is used to realize the function of the I / O module 8, that is, the input and output of data; the host computer includes the internal thermally coupled rectification tower control variable for calculating the output An ul...

Embodiment 2

[0105] refer to figure 1 with figure 2 , an ultra-high-purity self-adaptive nonlinear control method for an internal thermally coupled rectification column, the control method comprising the following steps:

[0106] 1) Determine the sampling period, and compare the relative volatility α, the pressure of the stripping section P s , Antonie constants a, b, c are stored in the historical database;

[0107] 2) Set the control law parameter k j1 , k j2 and the set value of the concentration of light components in the liquid phase at the top and bottom of the tower X 1 * , X n * ;

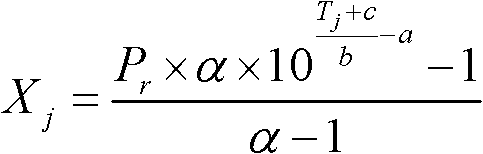

[0108] 3) Obtain the pressure P of the rectification section from the smart instrument r Pressure in the stripping section P s , and each tray temperature T j , to calculate the concentration of light components in the liquid phase, and use formula (1) (2) to get:

[0109] X j = P r ×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com