Process for producing boron-containing glass product and method for purifying waste gas generated in production of boron-containing glass product

A manufacturing method and boron glass technology, applied in glass manufacturing equipment, manufacturing tools, separation methods, etc., can solve problems such as adverse environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0137] The production method of the present invention will be described more specifically based on examples. However, the present invention is not limited to the following examples. In addition, in the following description, the description of the part related to the process with which the manufacturing method of a glass product is comprised normally, such as a forming process, an annealing process, and a cutting process in the manufacturing method of this invention, is abbreviate|omitted.

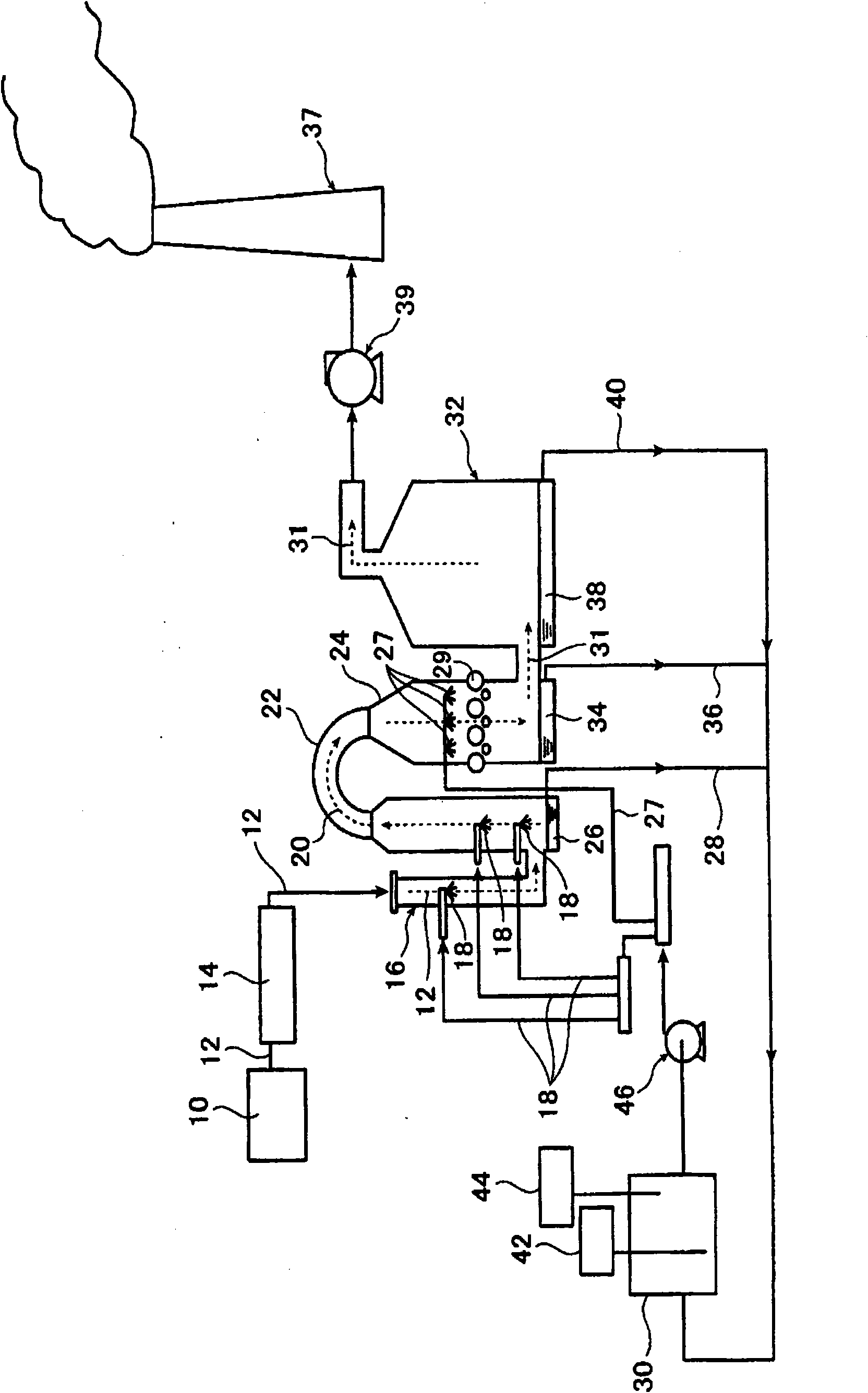

[0138] figure 1 is a schematic diagram of the production method of the present invention. figure 1 In the melting process, the exhaust gas 12 generated from the glass melting furnace 10 is supplied to the cooling tower 16 at a gas temperature of 135 to 155° C. through the bag filter 14 .

[0139] In the cooling tower 16, the cooling water 18 is sprayed with 1-3m 3 / h, three total 3 ~ 9m 3 / h Spray and contact the exhaust gas 12.

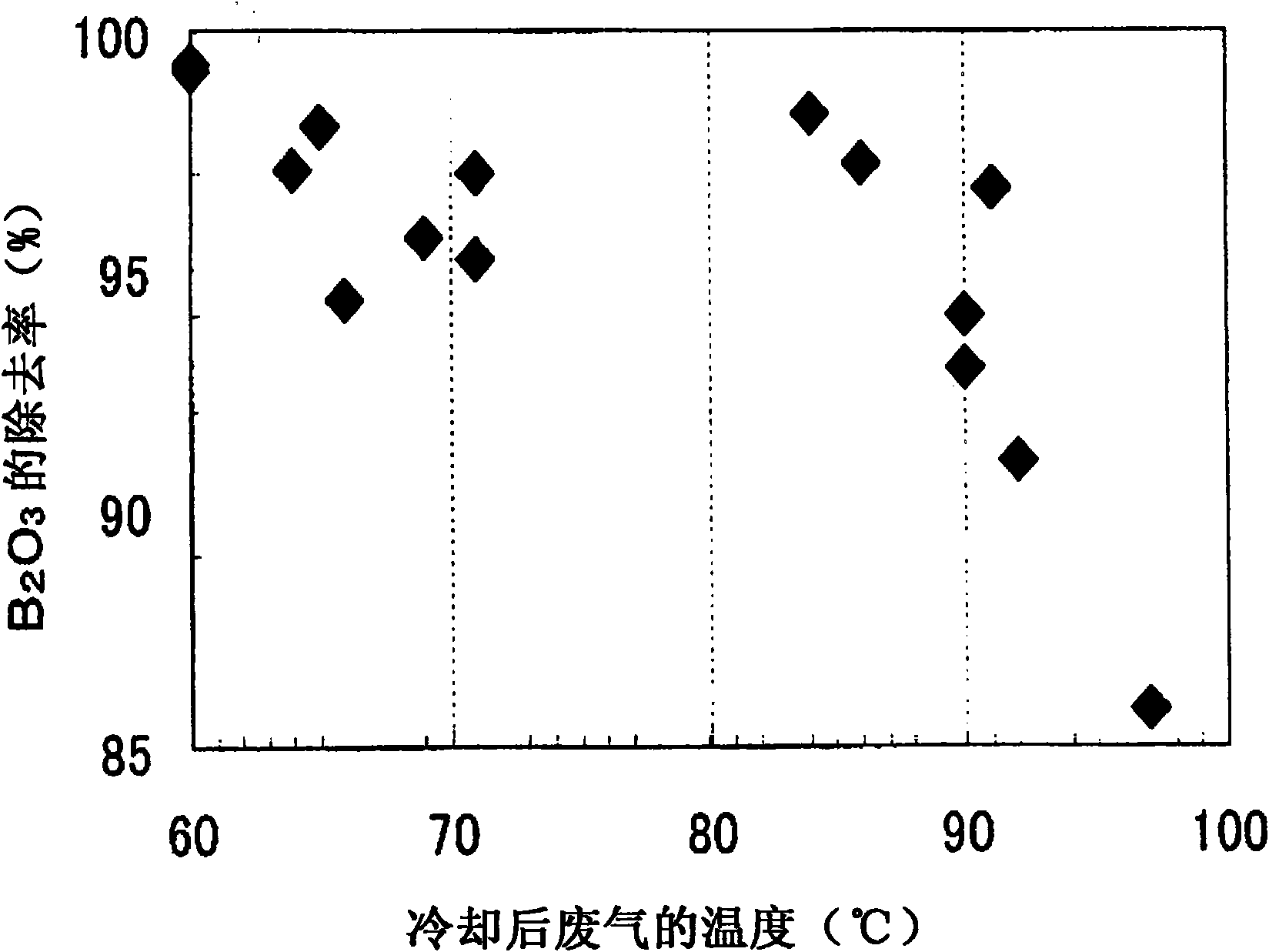

[0140] Also, the cooled exhaust gas 20 cooled to 65˜90...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap