Non-destructive inspection using laser- ultrasound and infrared thermography

A thermal imaging and inspection technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, optical testing of flaws/defects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention are shown in the drawings, and like numerals are used to refer to like and corresponding parts of the various drawings.

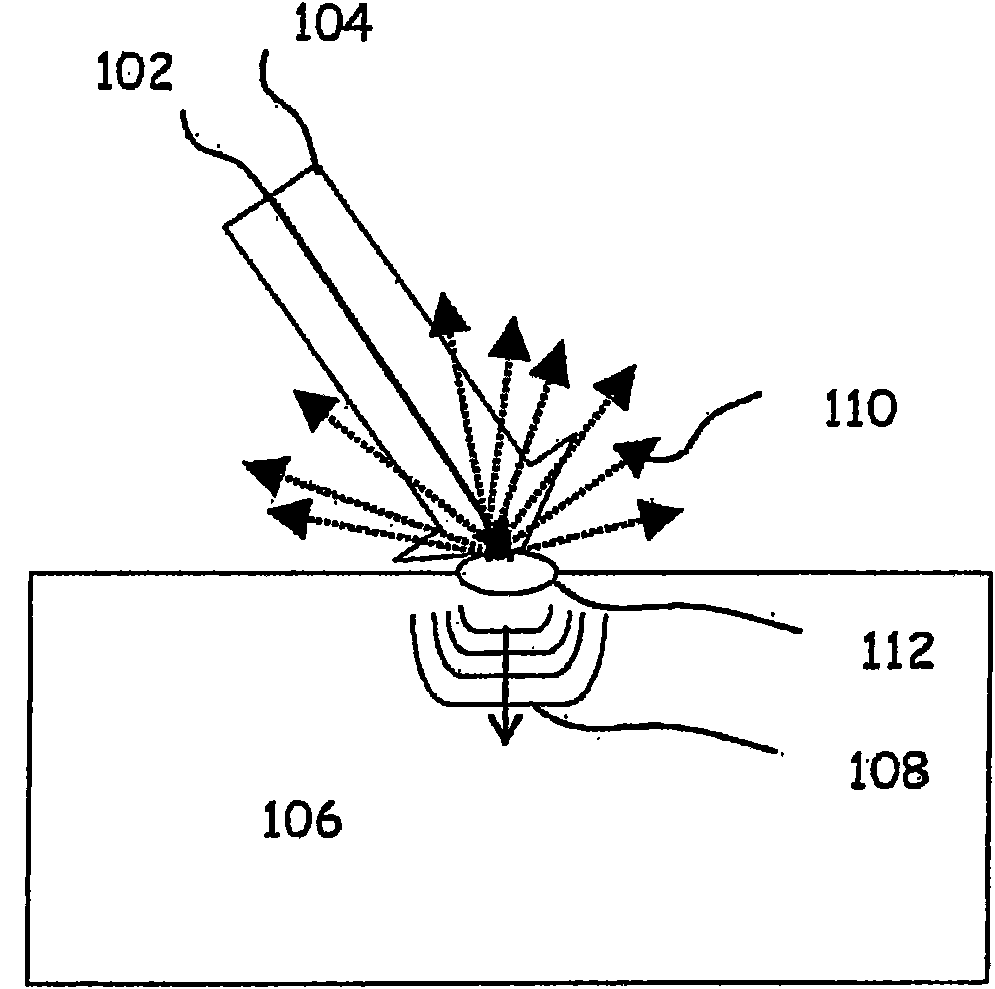

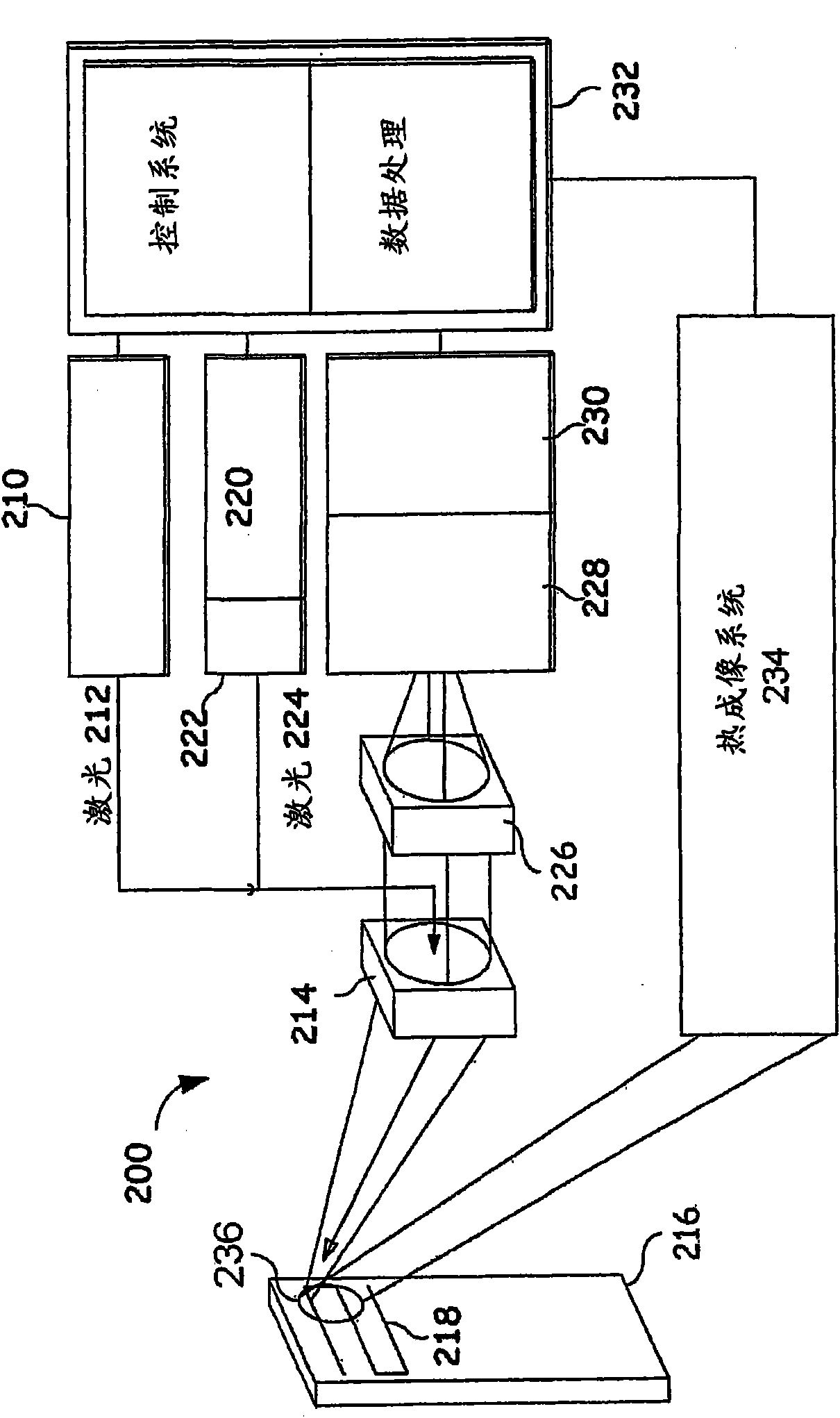

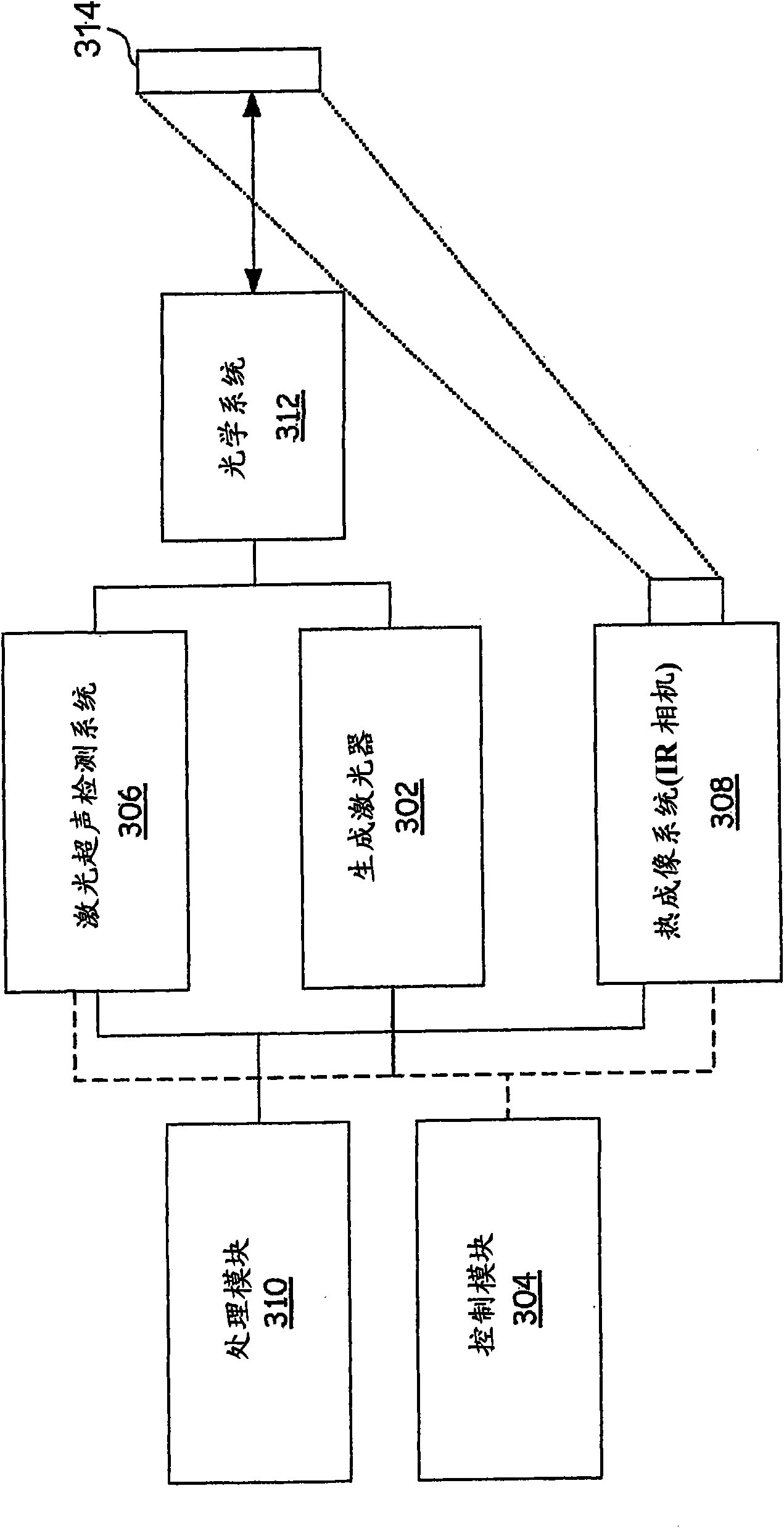

[0020] Embodiments of the present invention combine laser ultrasound and thermal imaging techniques to provide a more complete non-destructive inspection of target materials such as, but not limited to, polymeric matrix components (ie, composite materials). One embodiment provides an inspection system operable to inspect the internal structure of a target material. The inspection system includes a laser generator, an ultrasonic inspection system, a thermal imaging system, and a processor / control module. A generating laser generates a pulsed laser beam operable to induce ultrasonic displacement and thermal transients in a target material. Ultrasonic inspection systems detect ultrasonic surface displacements in target materials. Thermal imaging systems detect thermal transients in target materials. A pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com