Method for producing autoclaved aerated concrete from double siliceous raw materials

A technology for autoclaving and production methods, which is applied in the production of ceramic materials, climate sustainability, sustainable waste treatment, etc., can solve the problems of high production cost, low compressive strength, instability, etc., and achieve stable product quality. , the effect of reducing production costs and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

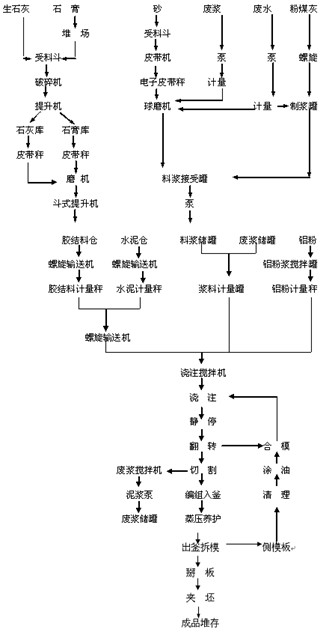

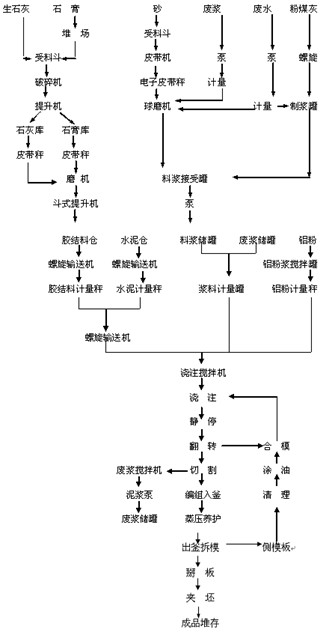

Method used

Image

Examples

Embodiment 1

[0029] Example 1. The invention discloses a production method for producing autoclaved aerated concrete from double siliceous raw materials. Two siliceous materials, quartz sand and fly ash, cement, quicklime, and gypsum powder are used as main raw materials, and aluminum powder paste air-generating agent is added to make autoclaved aerated concrete according to the conventional autoclaved aerated concrete preparation process; The weight percentage of raw materials is: quartz sand: fly ash: cement: quicklime: gypsum powder = 33%: 35%: 10%: 19%: 3%; aluminum powder paste dosage: 0.7‰, water-material ratio: 0.55. The water-material ratio refers to the ratio of the amount of water added to the powder. SiO in the two siliceous materials of quartz sand and fly ash in raw materials 2 The total content of ingredients is between 60% and 70%. Quartz sand complies with JC / T622-1996 "Sand for Silicate Building Products" standard, its SiO 2 ≥80%, K 2 O+NaO≤5%, organic matter: qualifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com