Sealing gasket for cylinder head cover

A technology for cylinder head covers and gaskets, which is applied in the direction of engine sealing, engine sealing devices, engine components, etc. It can solve the problems of reduced life of gaskets, crooked installation of gaskets, twisting and deformation, etc., so as to improve service life and benefit Assembling, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

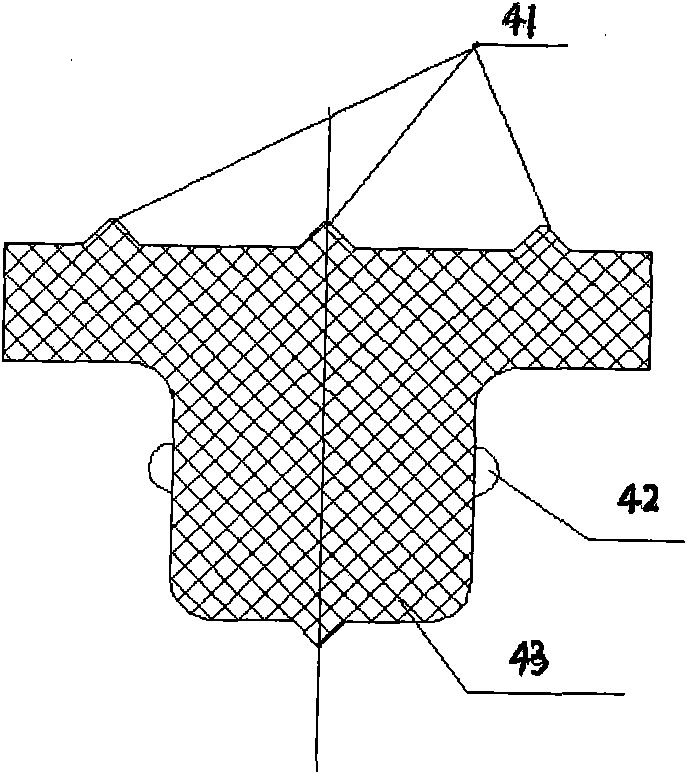

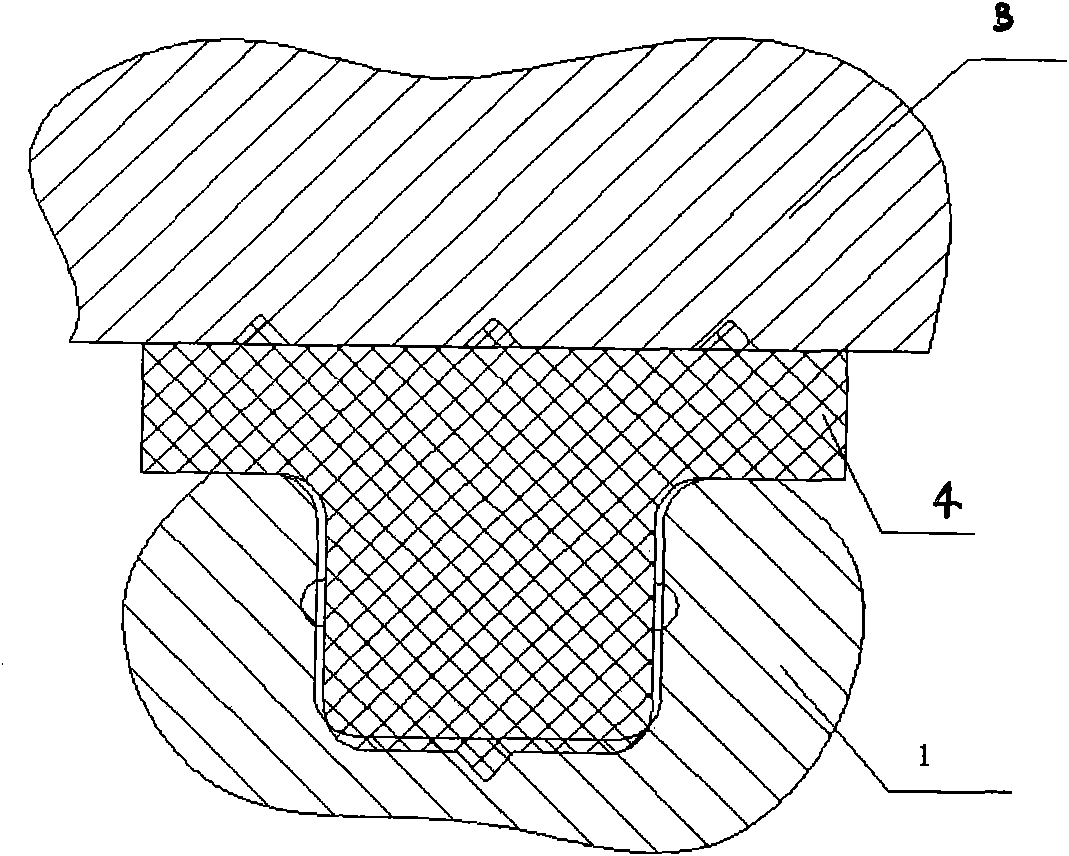

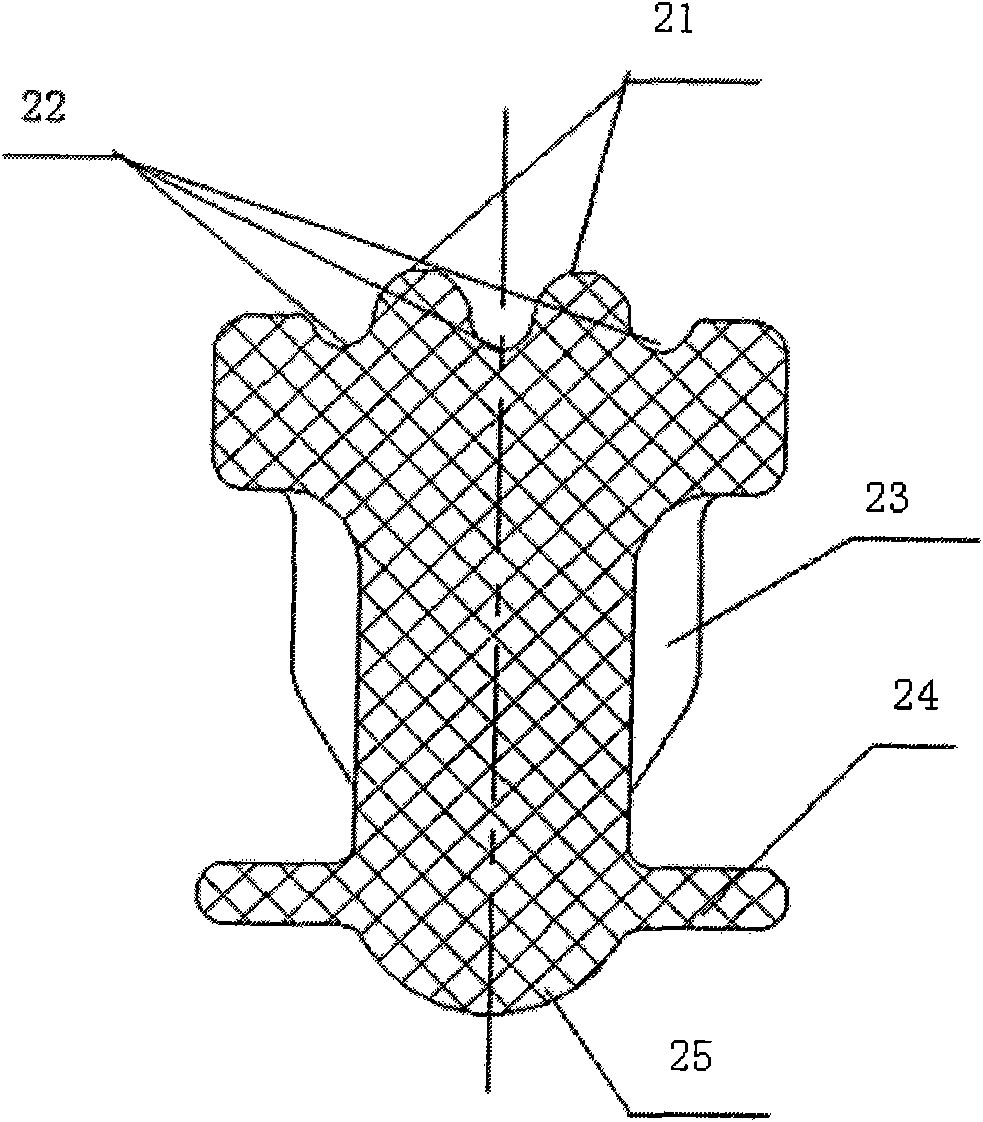

[0022] Such as image 3 As shown, the section upper portion of the improved gasket 1 of the present invention is "T"-shaped, and two parallel closed semicircular sealing ribs 21 and three parallel sealing ribs 21 are arranged on the joint surface between the upper part of the gasket and the cylinder head. The oil storage tank 22 is located on both sides of the sealing rib 21 and between them. Long arc strip bosses 23 are arranged vertically on both sides of the waist-shaped part of the section of the gasket, which are arranged at intervals along the length direction of the gasket. A pair of wing-like edges 24 protruding to both sides are designed at the middle and lower part of the "T" section, and the lower end of the gasket is designed as a semicircular structure 25.

[0023] The gasket adopts ethylene acrylate rubber material with a Shore hardness of 60, high temperature resistance and low compression set, which improves the service life and sealing performance of the gask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com