Fault diagnosis method of large-sized photovoltaic array

A photovoltaic array and fault diagnosis technology, applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of difficult to achieve online fault diagnosis and alarm, inability to distinguish whether the temperature difference is not obvious, accuracy and efficiency depend on, etc. The effect of accurate and reliable measurement results, fast measurement and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

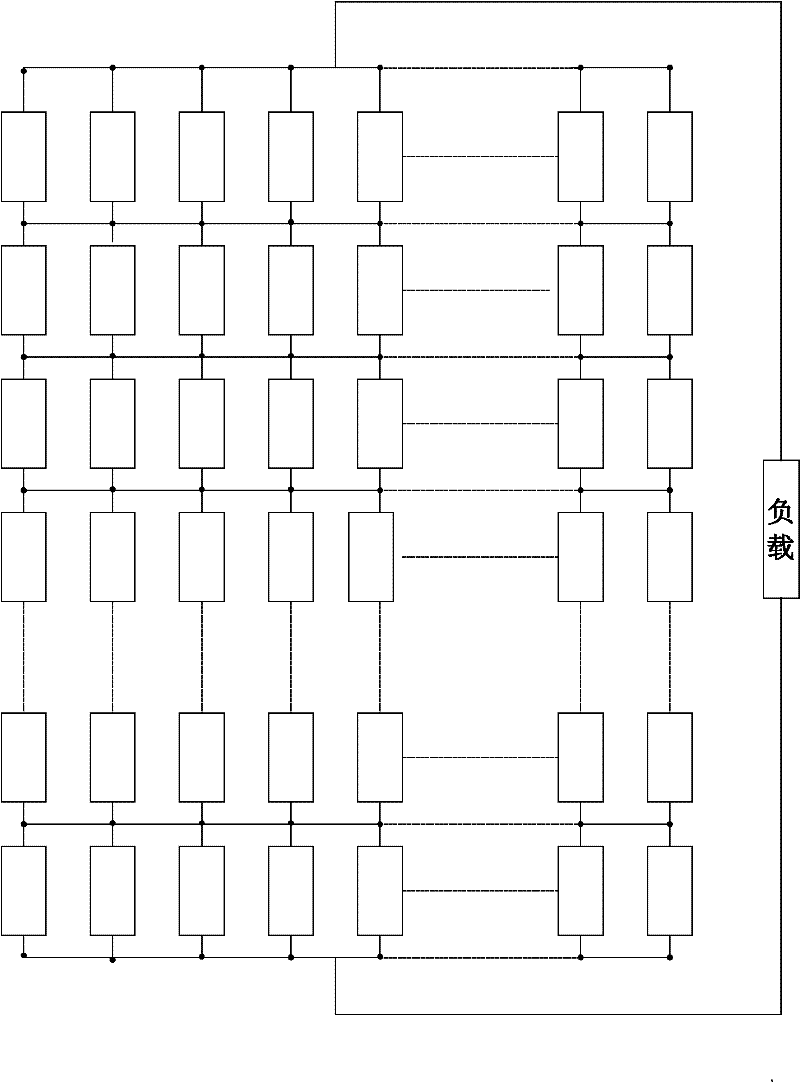

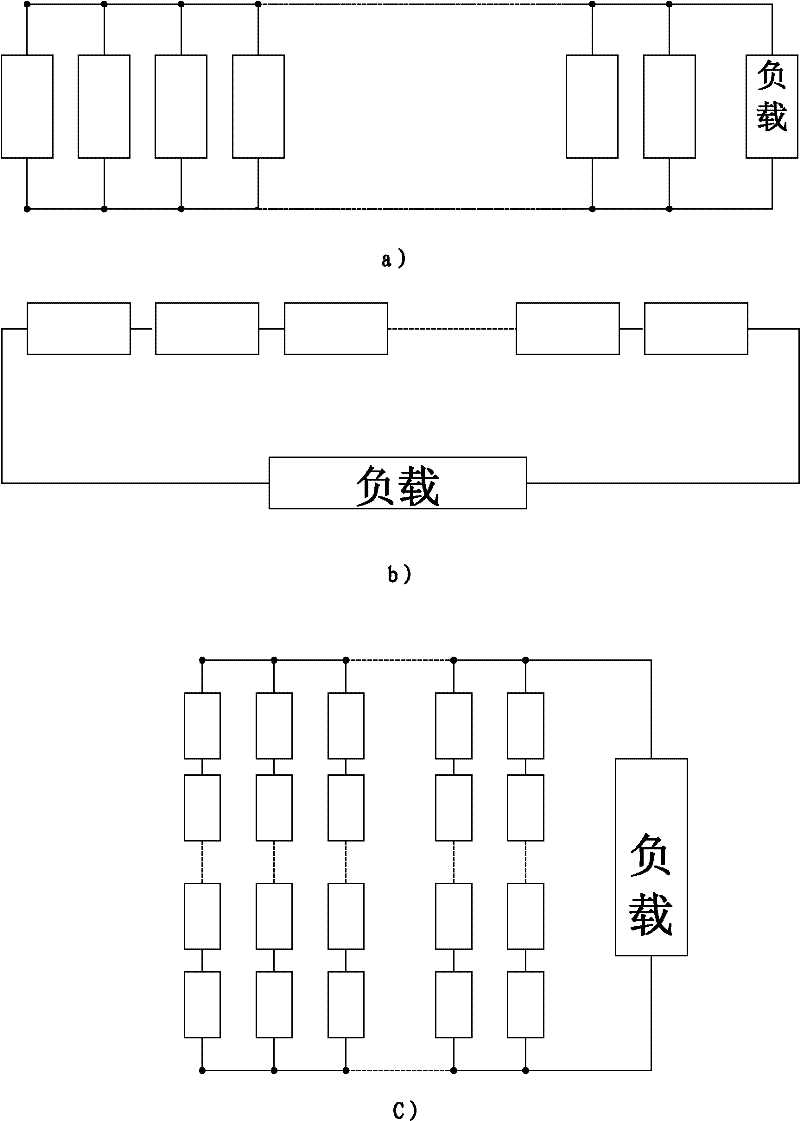

[0020] In the present invention, the battery panels are connected in parallel first and then in series, and the photovoltaic array structure formed by the battery panels in this way is called a TCT structure. figure 1 It is a schematic diagram of a photovoltaic array with a TCT structure. Compared with the other three connection methods of battery panels (series connection, parallel connection, first series connection and then parallel connection), this connection method is easy to detect the location of a faulty photovoltaic cell. figure 2 It is a schematic diagram of the other three connection methods of the battery board.

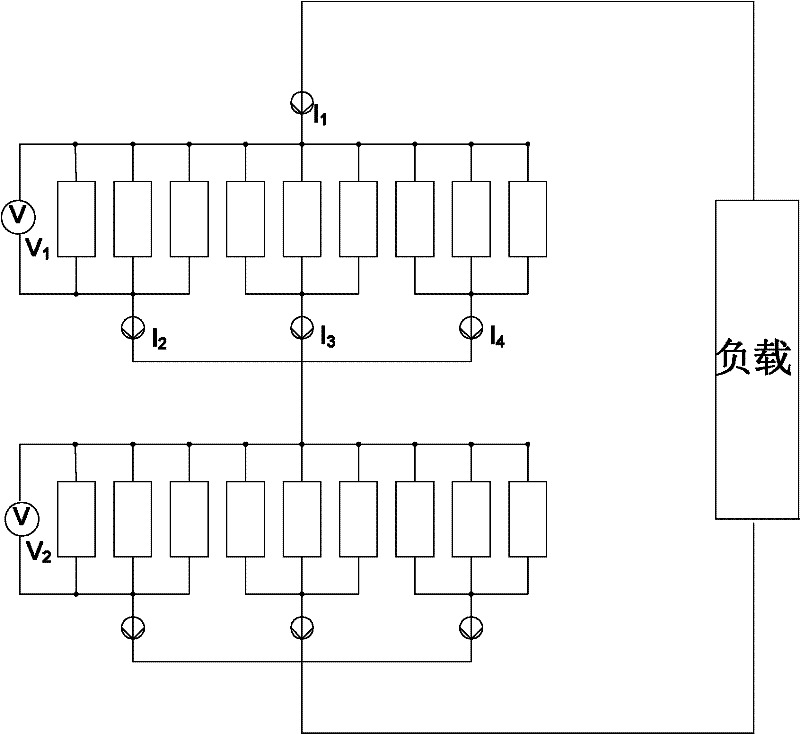

[0021] The connection mode of the sensor in the present invention is as follows: the current sensor should be connected in series in the circuit under test to measure the current. Since the internal resistance of the current sensor is very small, the connection mode of the battery boards in parallel first and then in series remains unchanged. The voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com