Plastic bracket structure of quadrupole motor

A technology for plastic brackets and motors, which is applied in the direction of structural connection, casing/cover/support, electrical components, etc., can solve the problems of limited internal space of the motor, inconvenient motor assembly, too long and loose wires, etc., to reduce the internal space. , The effect of simple assembly and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0024] A preferred embodiment is given below:

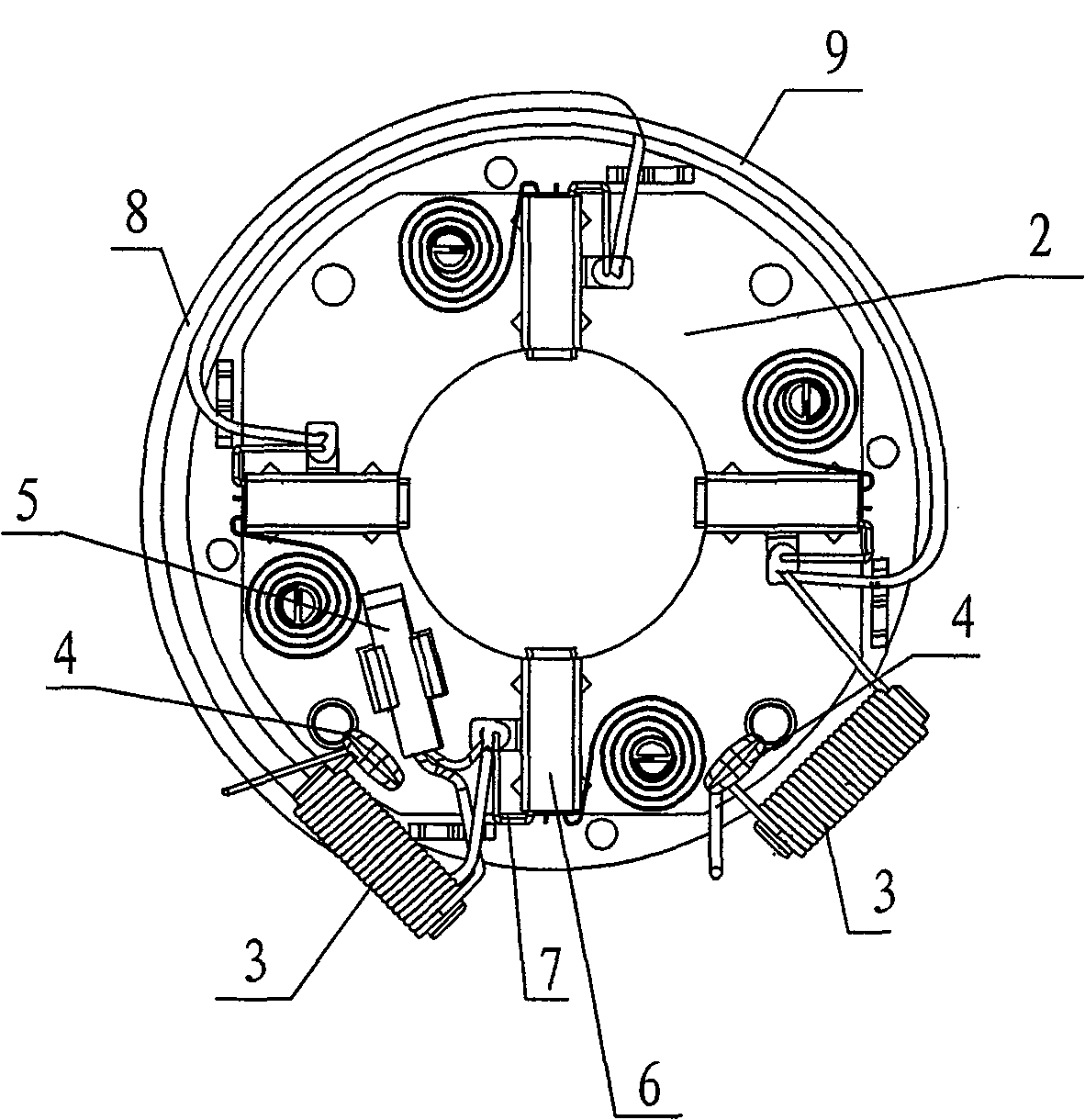

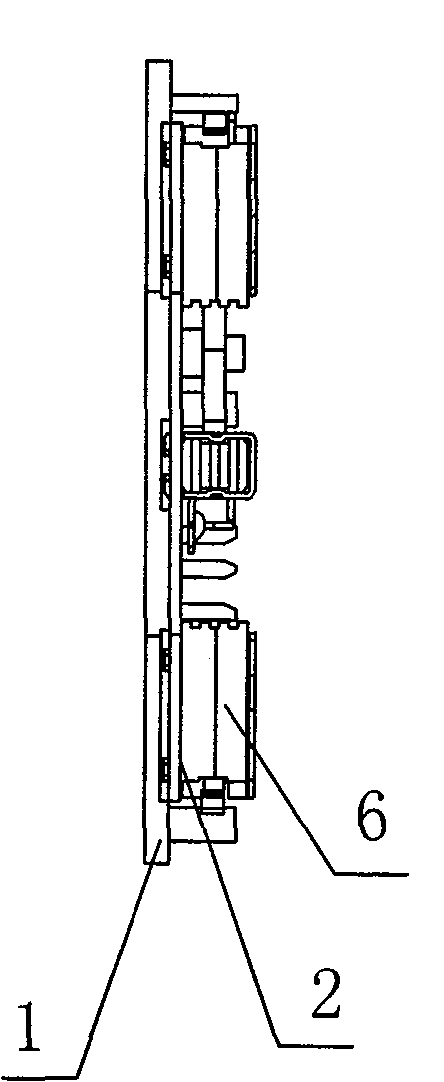

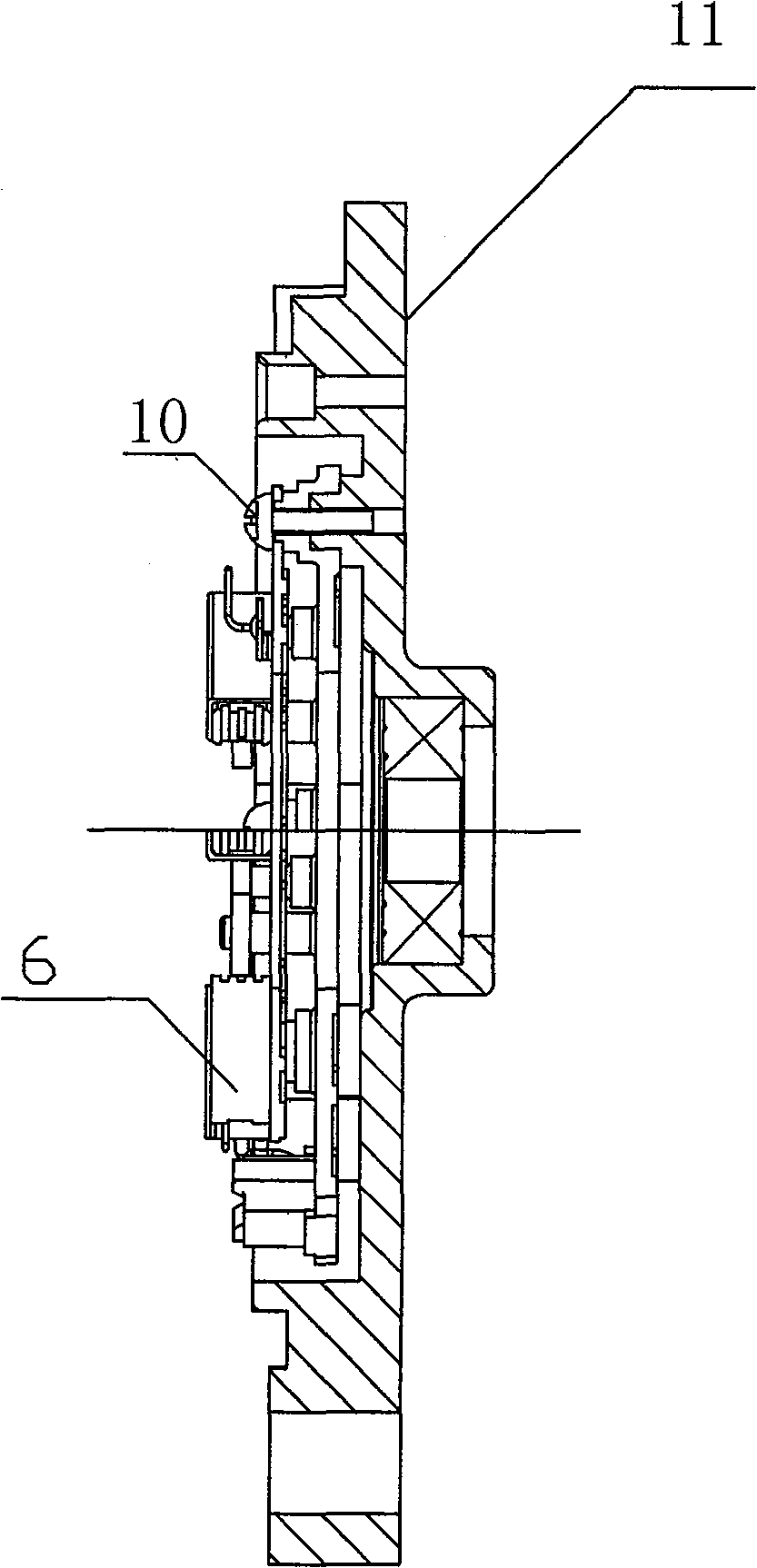

[0025] according to Figure 1 to Figure 4 As shown, a plastic bracket structure of a four-pole motor includes a plastic bracket 1, a circuit board 2 is arranged above the plastic bracket 1, an inductor 3, a capacitor 4 and a thermal protector 5 are fixed on the circuit board 2, and A brush box 6 is riveted, and a carbon brush wire 7 is welded on the brush box 6. The capacitor 4 is respectively connected to the inductor 3 and the thermal protector 5, and the circuit board 2 is also respectively connected to a positive connecting wire 8 and a negative connecting wire. Wire 9.

[0026] There are two inductors 3, which are respectively connected to the positive connection wire 8 and the negative connection wire 9.

[0027] The outside of the plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com