Galvanized greenblack passivation solution and preparation method thereof

A passivation solution, dark green technology, applied in the coating process of metal materials, etc., can solve the problems of coating darkening, white corrosion, and the preparation method of galvanized dark green passivation solution that has not yet been seen, achieving soft luminosity, Good adhesion and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

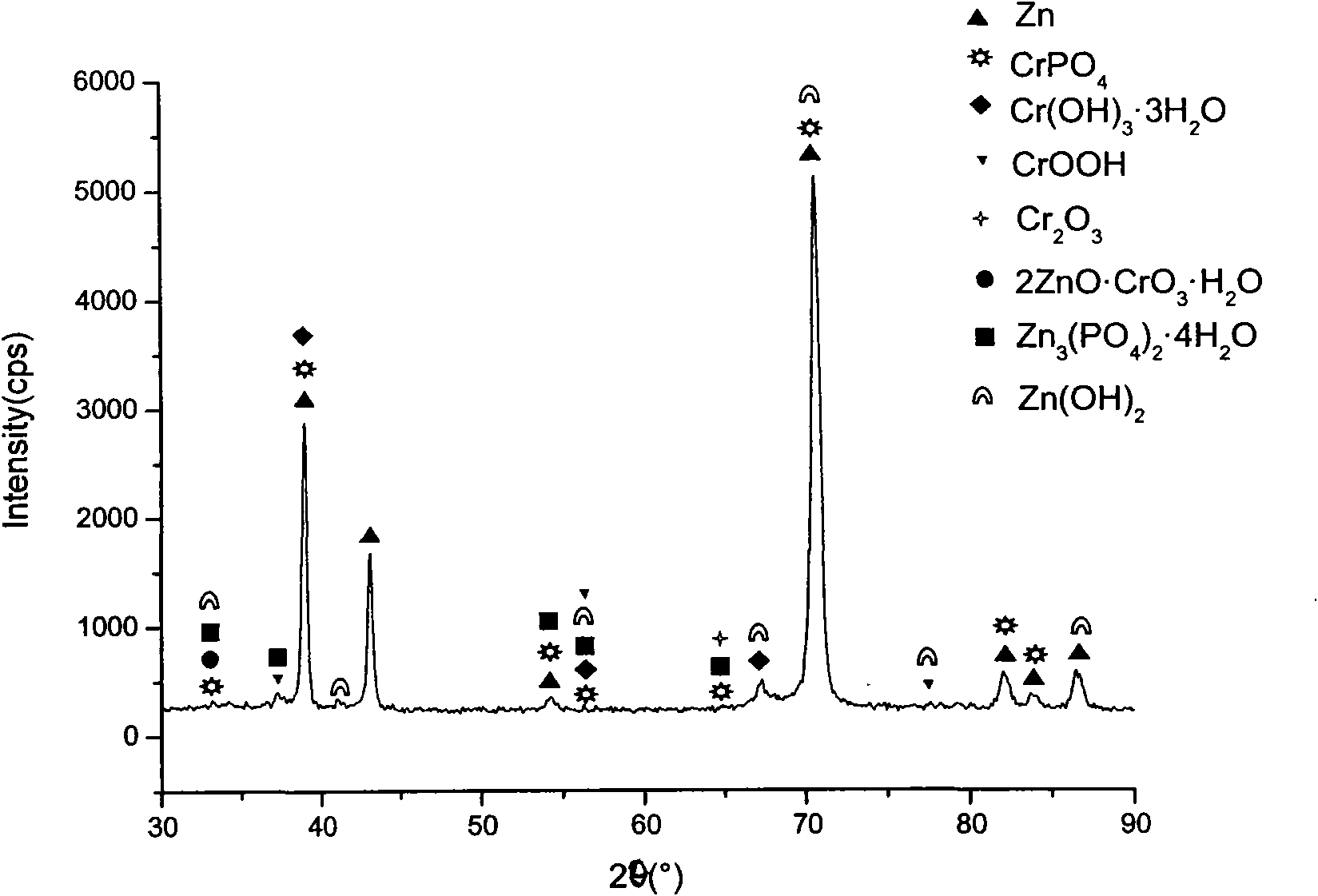

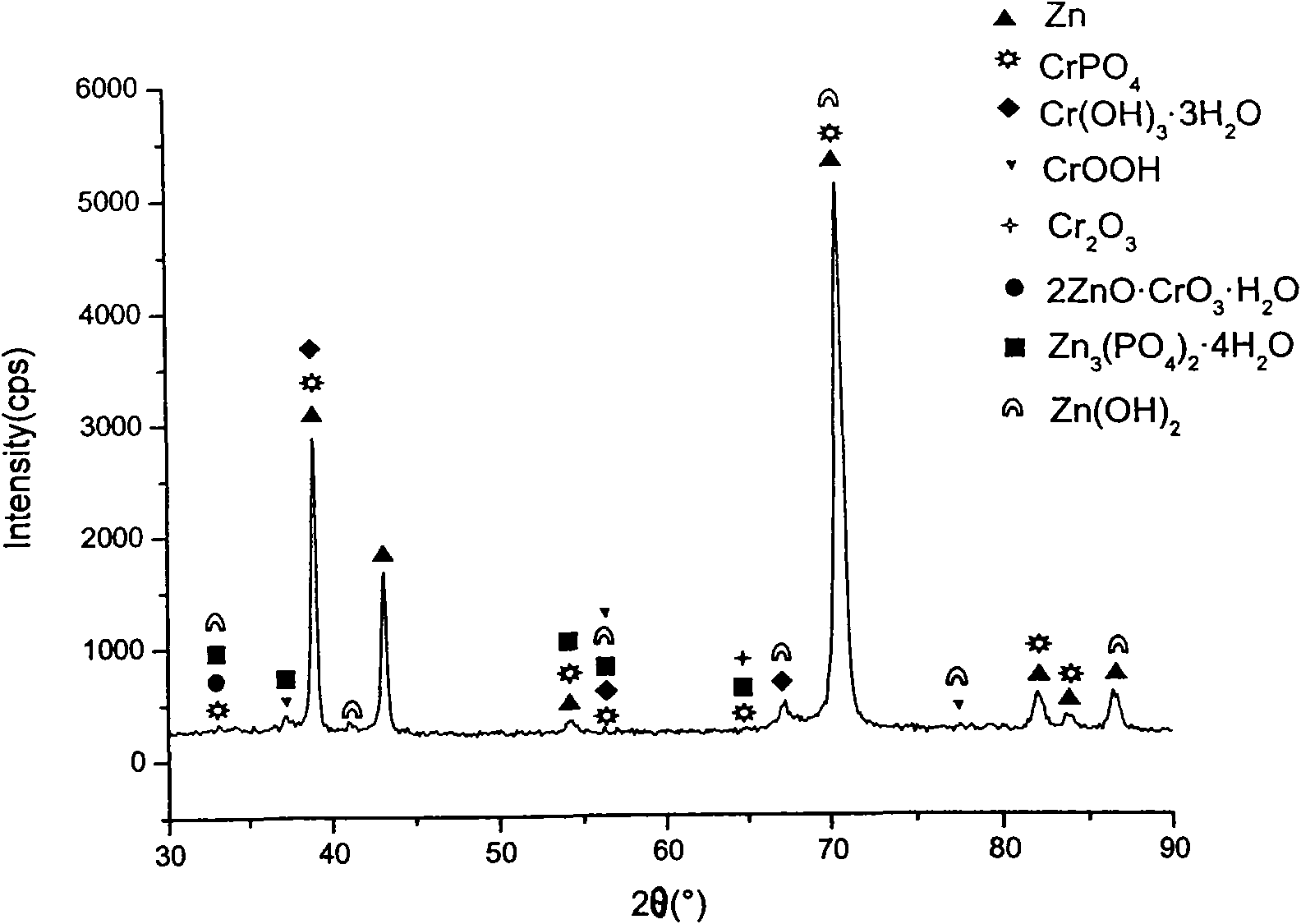

Image

Examples

Embodiment 1

[0024] Embodiment 1, the component of every liter of passivation solution in the present embodiment is:

[0025] Chromic anhydride 20(g / L);

[0026] Phosphoric acid / (d=1.7) 11(ml / L);

[0027] Nitric acid / (d=1.4) 2.5(ml / L);

[0028] Sulfuric acid / (d=1.84) 2.5(ml / L);

[0029] Glacial acetic acid 4-5(ml / L);

[0030] Silver nitrate 0.008(g / L);

[0031] The balance is deionized water.

[0032] According to the amount of preparing 2000L passivation solution in this embodiment, its preparation method is as follows:

[0033] a. Pre-inject 1000L deionized water into the passivation tank with a volume of 3m3, then add the required amount of chromic anhydride according to the proportion of the above components, stir fully to dissolve it, and then add the required amount of phosphoric acid, nitric acid, Sulfuric acid, glacial acetic acid and silver nitrate, among which silver nitrate should be dissolved in deionized water in a beaker before adding to the passivation tank;

[0034] ...

Embodiment 2

[0039] Embodiment 2, the component of every liter of passivation solution of the present embodiment is:

[0040] Chromic anhydride 25(g / L);

[0041] Phosphoric acid / (d=1.7) 10(ml / L);

[0042] Nitric acid / (d=1.4) 2 (ml / L);

[0043] Sulfuric acid / (d=1.84) 2 (ml / L);

[0044] Glacial acetic acid 4-5(ml / L);

[0045] Silver nitrate 0.007(g / L);

[0046] The balance is deionized water.

[0047] Other technical features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0048] Embodiment 3, the component of every liter of passivation solution in the present embodiment is:

[0049] Chromic anhydride 23(g / L);

[0050] Phosphoric acid / (d=1.7) 10(ml / L);

[0051] Nitric acid / (d=1.4) 2.2(ml / L);

[0052] Sulfuric acid / (d=1.84) 2.3(ml / L);

[0053] Glacial acetic acid 4-5(ml / L);

[0054] Silver nitrate 0.008(g / L);

[0055] The balance is deionized water.

[0056] Other technical features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com