Pulverized coal fired boiler wall type oscillating low NOx over-fire air device

A pulverized coal boiler and burn-out air technology, which is applied to combustion equipment, lighting and heating equipment, etc., can solve the problems of increasing system complexity and operating costs, failing to reach burn-out air, affecting boiler efficiency, etc. The effect of improving the penetration capacity, strengthening the burnout and ensuring the efficiency of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

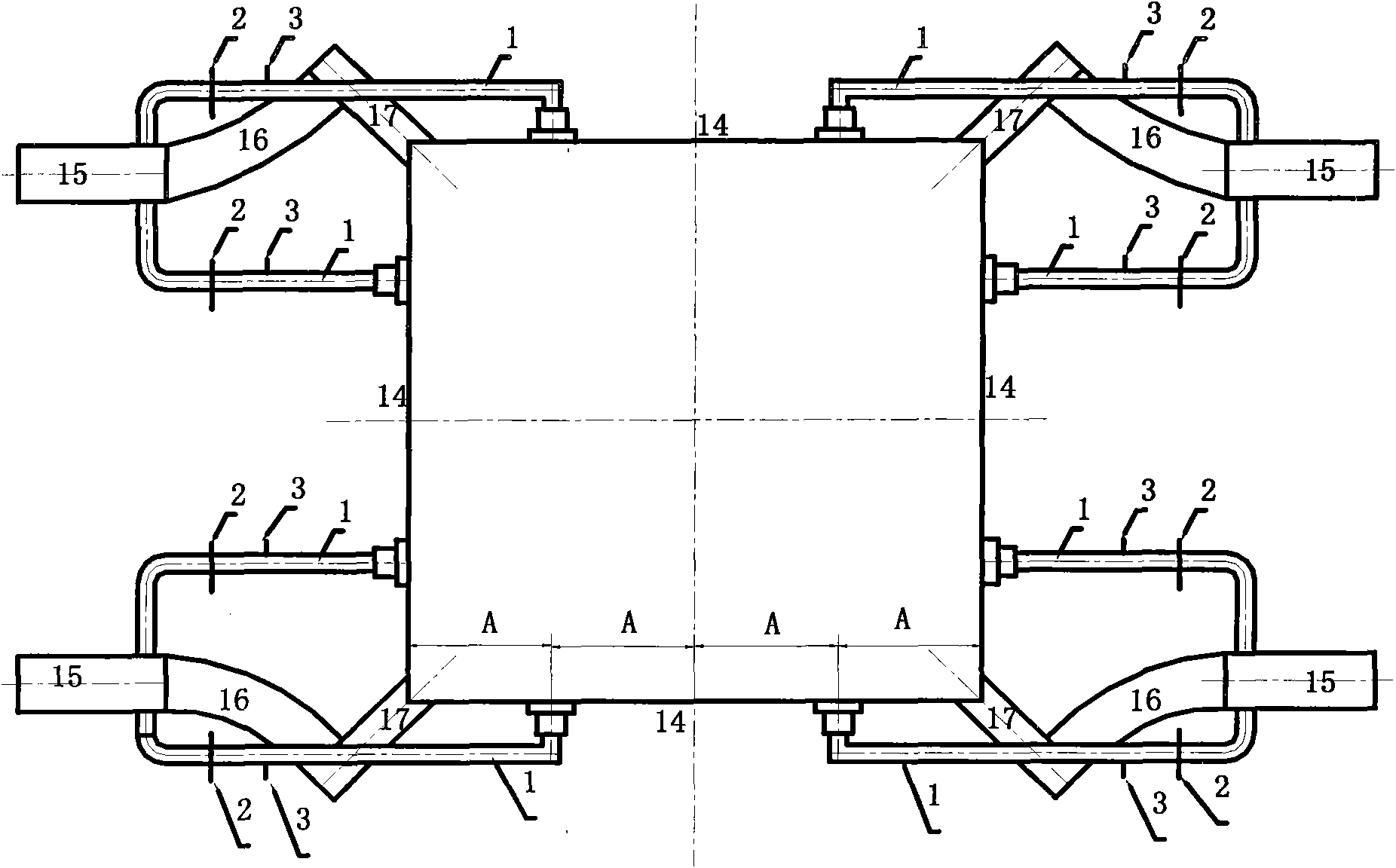

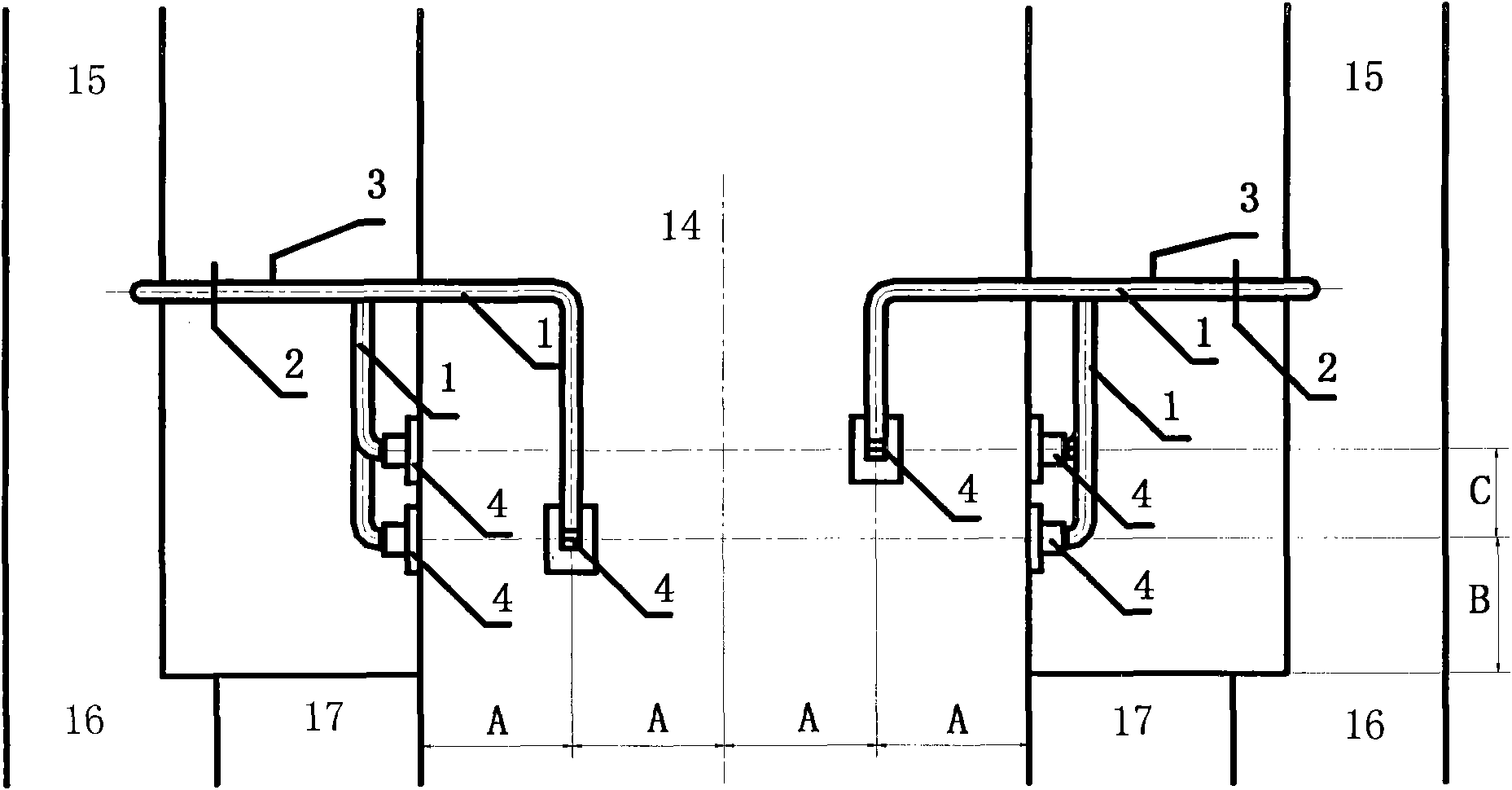

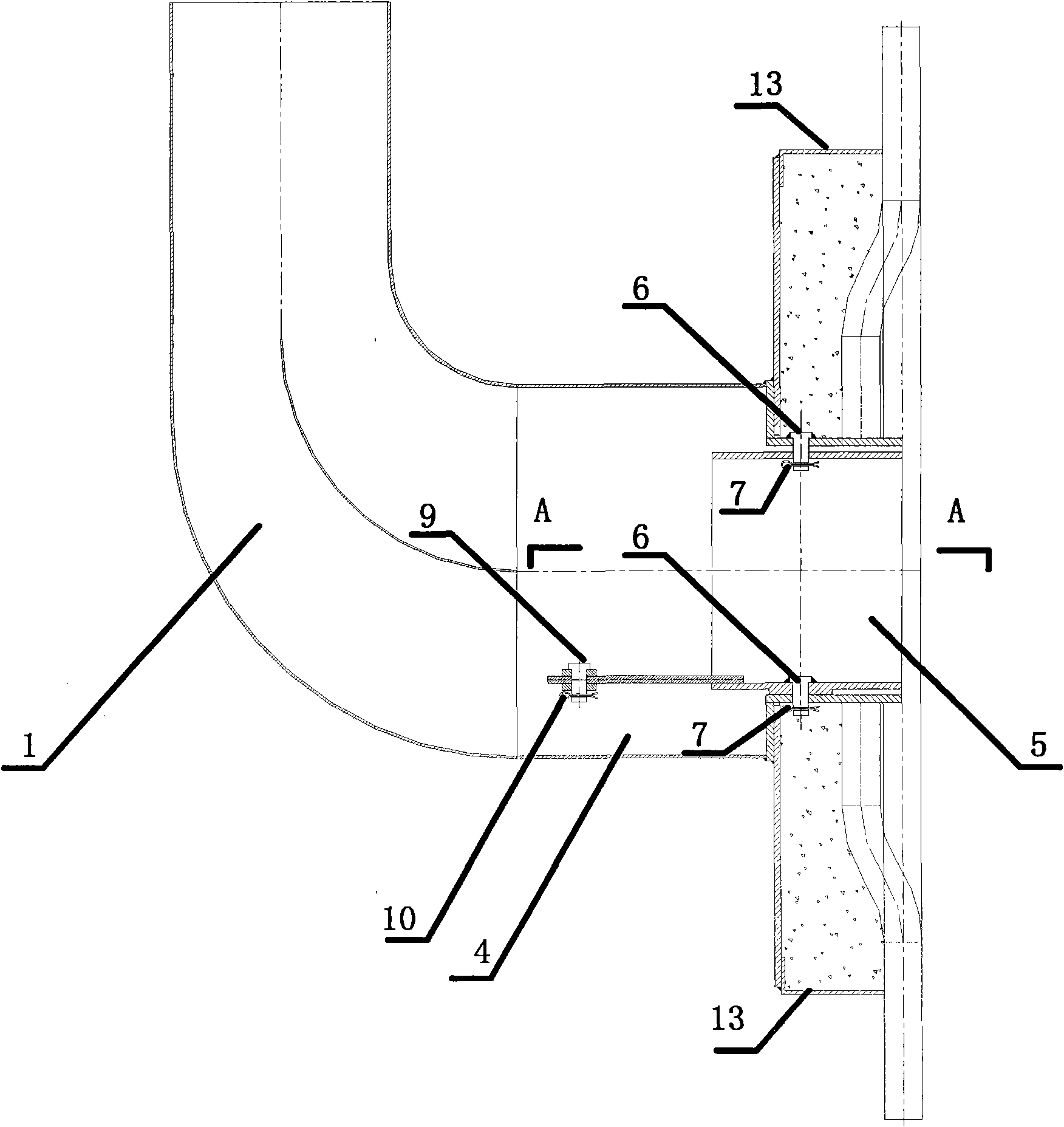

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the outer wall of the square furnace wall 14 of the present invention is provided with a group of overfire air devices respectively. The upper part of the burner area; each overburning air component includes the overburning air pipe 1, the overburning damper 2, the overburning air speed measuring back pipe 3, the overburning air bellows 4, the swing type overburning air nozzle 5, the nozzle shaft pin 6, Nozzle shaft cotter pin 7, swing adjustment mechanism 8, swing transmission pin 9, swing cotter pin 10, furnace wall cover plate 11, side wall plate 12 and comb plate 13; a hole is opened in the furnace wall 14 on the upper part of the burner area, and the furnace wall 14 Rectangular side wall panels 12 are arranged on the left and right sides of the upper water cooling wall hole, and one long side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap