CNC elbow processing-oriented coding control system and decoding control system

A coding system and pipe bending technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of repeated development, waste of resources, incompatibilities, and high development costs, so as to achieve easy learning and Promote, avoid repeated development, and reduce development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

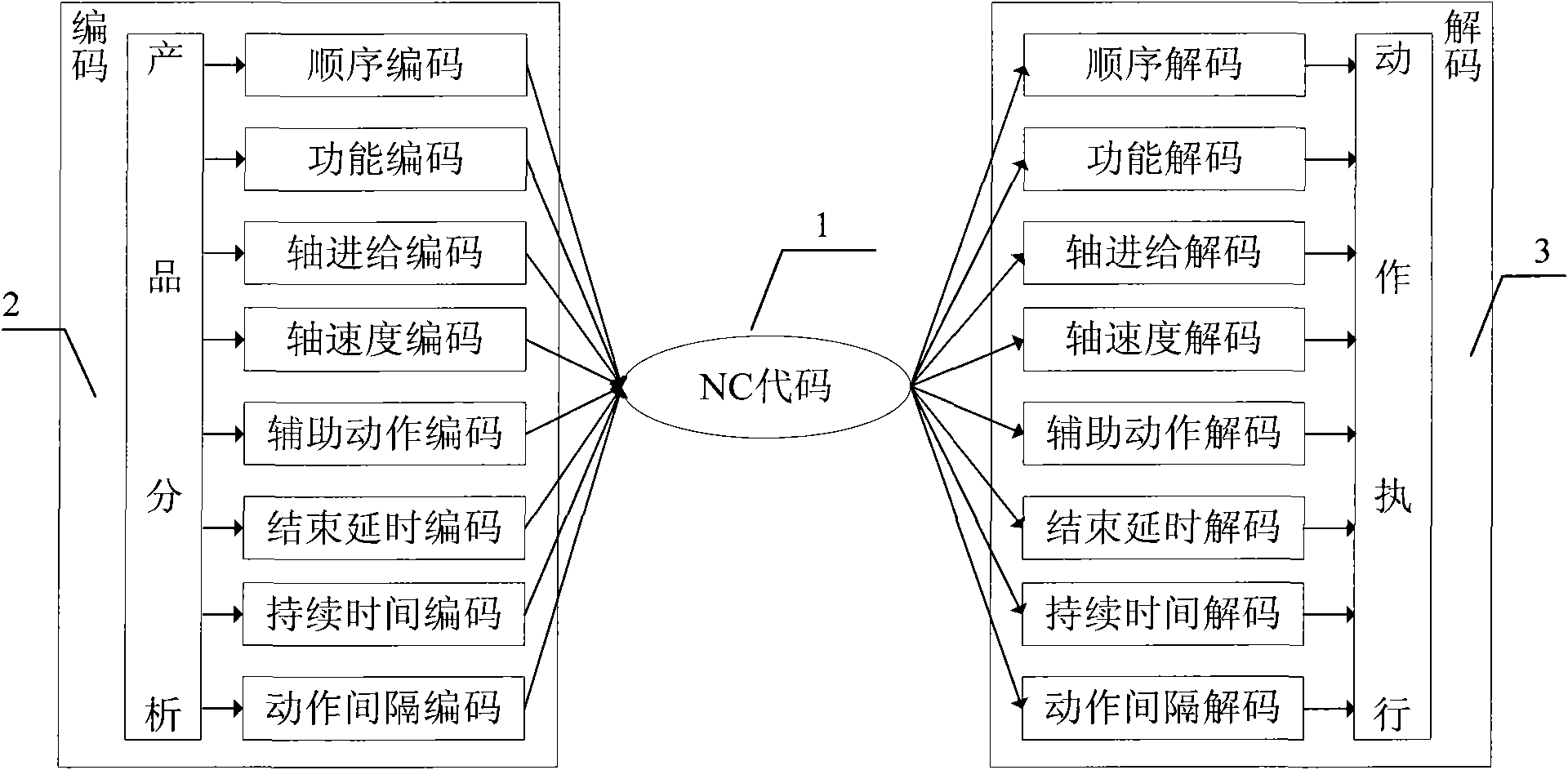

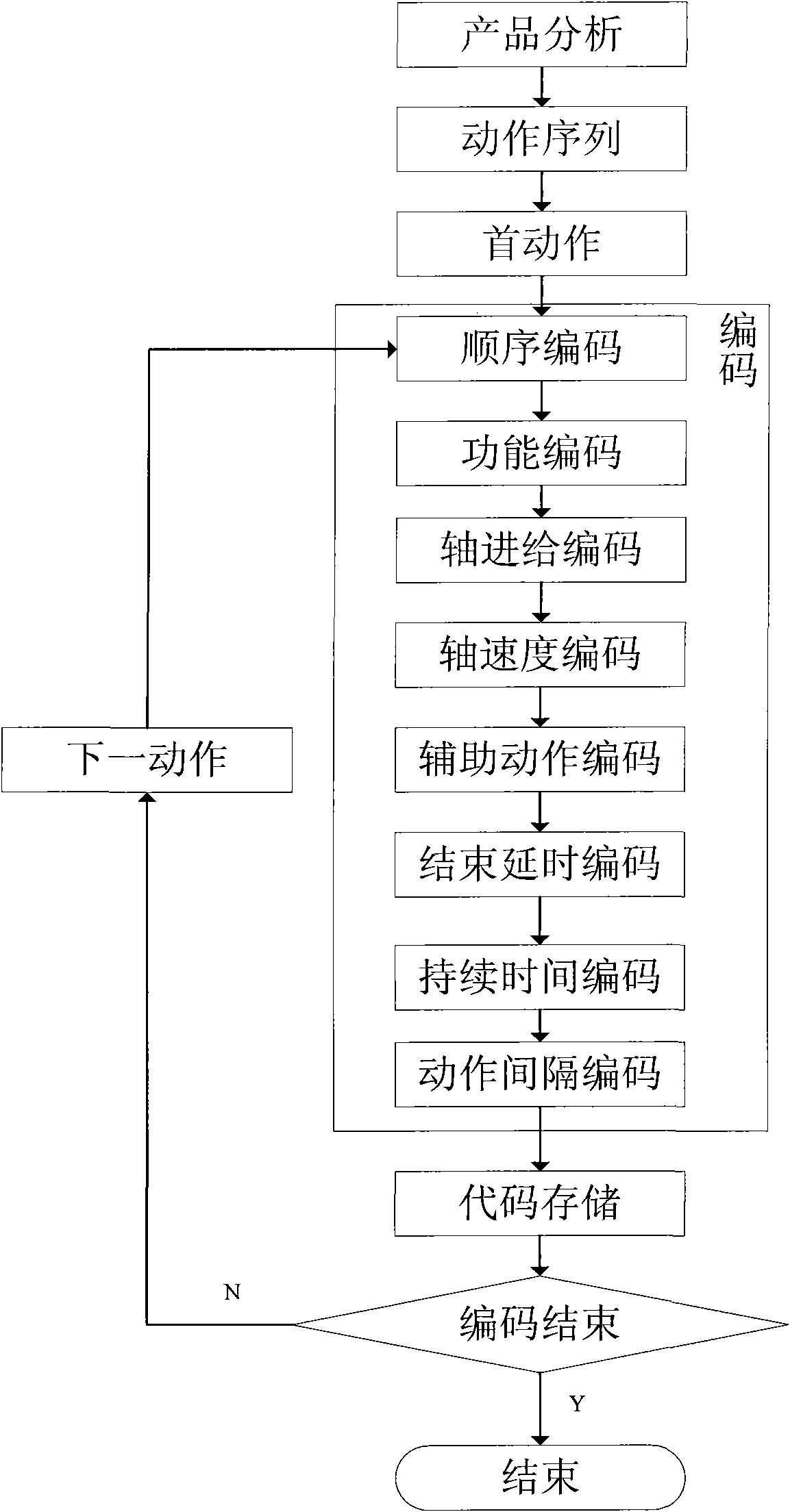

[0056] refer to figure 1 and figure 2 , a coding control system oriented to CNC pipe bending, the coding control system includes NC code rules and a coding module, and the NC code rules include:

[0057] Sequence code N, used to describe the position of the current NC code in the entire action sequence;

[0058] Function code G, used to describe the basic functions realized by the current NC code;

[0059] Axis feed code, used to describe the feed amount of a specific axis;

[0060] Axis speed code, used to describe the feed speed or rotational speed of a specific axis;

[0061] Auxiliary action code M, used to describe specific auxiliary actions for processing;

[0062] End delay code D, used to describe the delay waiting time after the current action ends;

[0063] The continuous delay code T is used to describe the holding time of the current action;

[0064] Action interval code I, which is used to describe the interval between the opening times of different axes du...

Embodiment 2

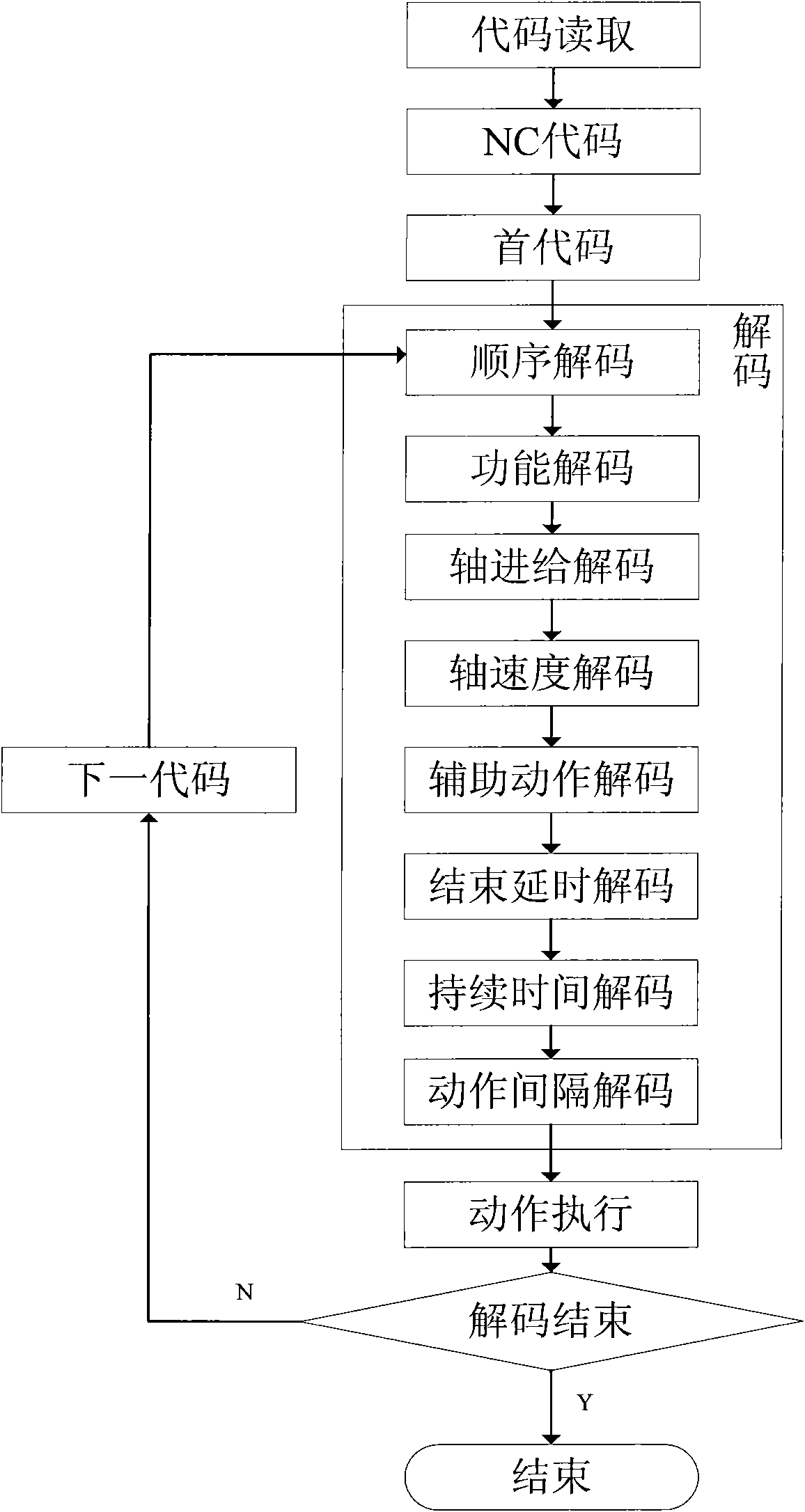

[0152] refer to figure 1 and image 3 , a decoding control system oriented to CNC pipe bending, the decoding control system includes NC code rules and a decoding module, and the NC code rules include:

[0153] Sequence code N, used to describe the position of the current NC code in the entire action sequence;

[0154] Function code G, used to describe the basic functions realized by the current NC code;

[0155] Axis feed code, used to describe the feed amount of a specific axis;

[0156] Axis speed code, used to describe the feed speed or rotational speed of a specific axis;

[0157] Auxiliary action code M, used to describe specific auxiliary actions for processing;

[0158] End delay code D, used to describe the delay waiting time after the current action ends;

[0159] The continuous delay code T is used to describe the holding time of the current action;

[0160] Action interval code I, which is used to describe the interval between the opening times of different ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com