Method and devices for handling rod-like pieces in drilling and bolting

A technology for drilling rods and rock bolts, applied in the field of slender rods, can solve problems such as insufficient operational reliability and complex structures, and achieve the effects of easy control and automation, simple operation, and reduced swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

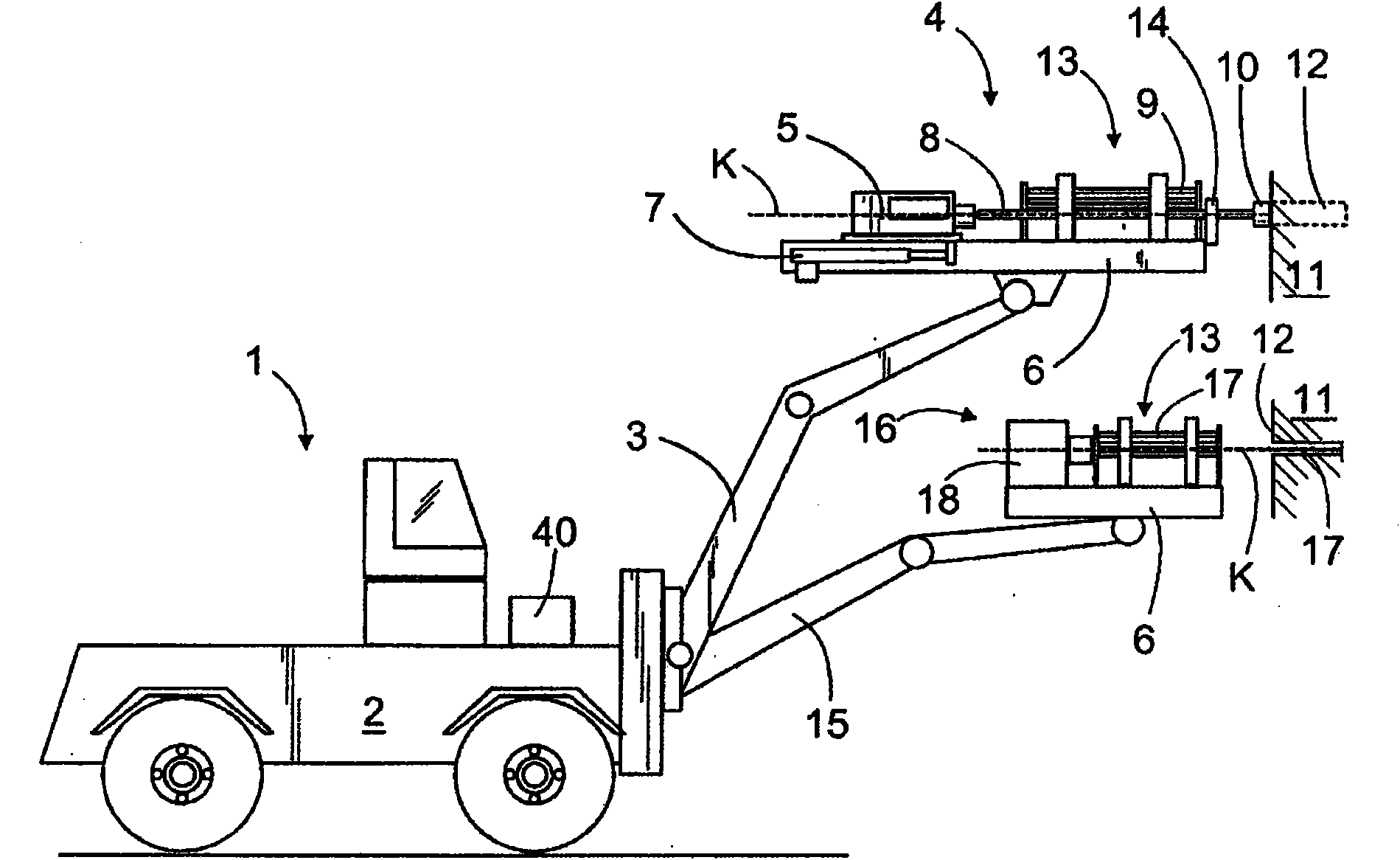

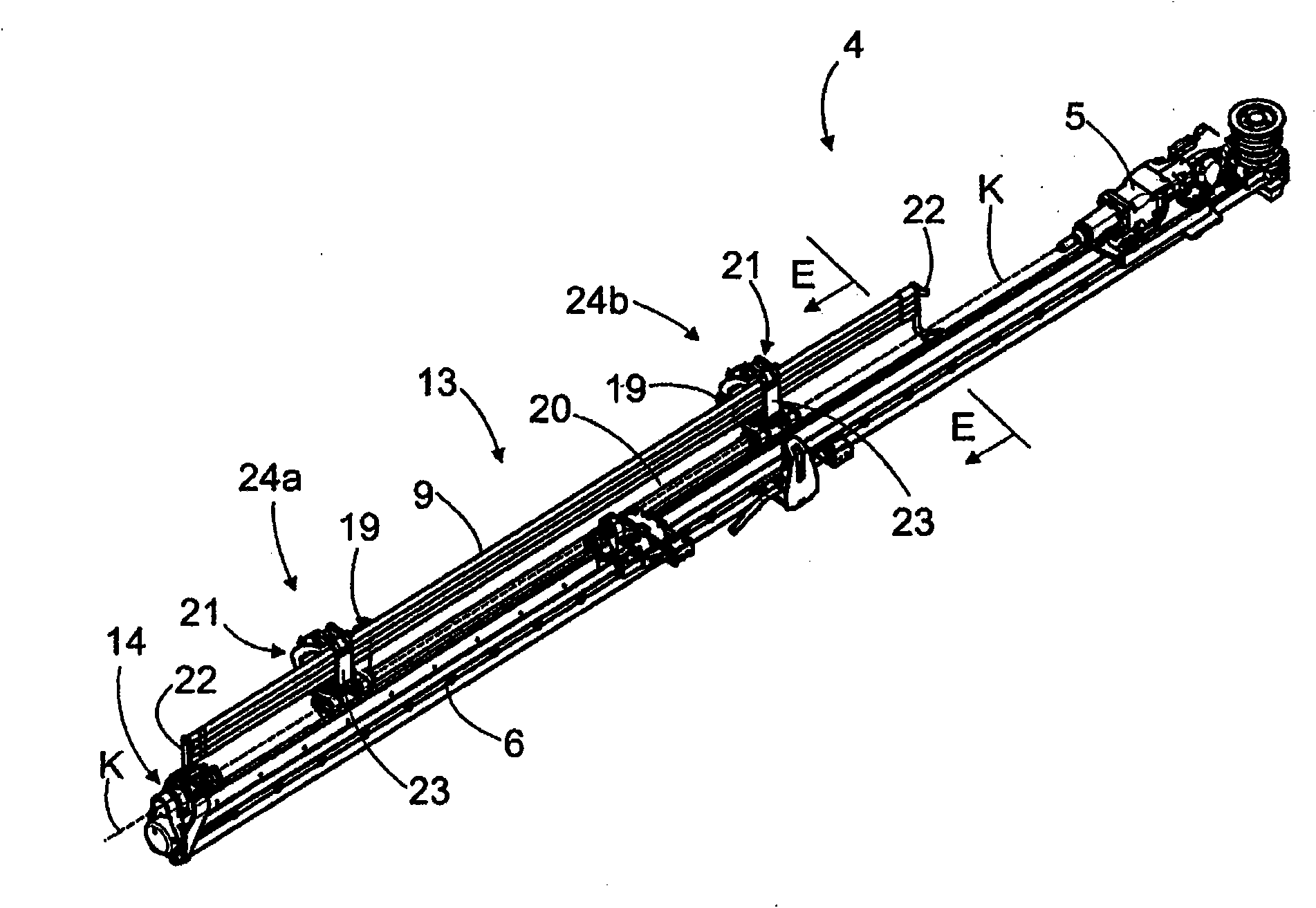

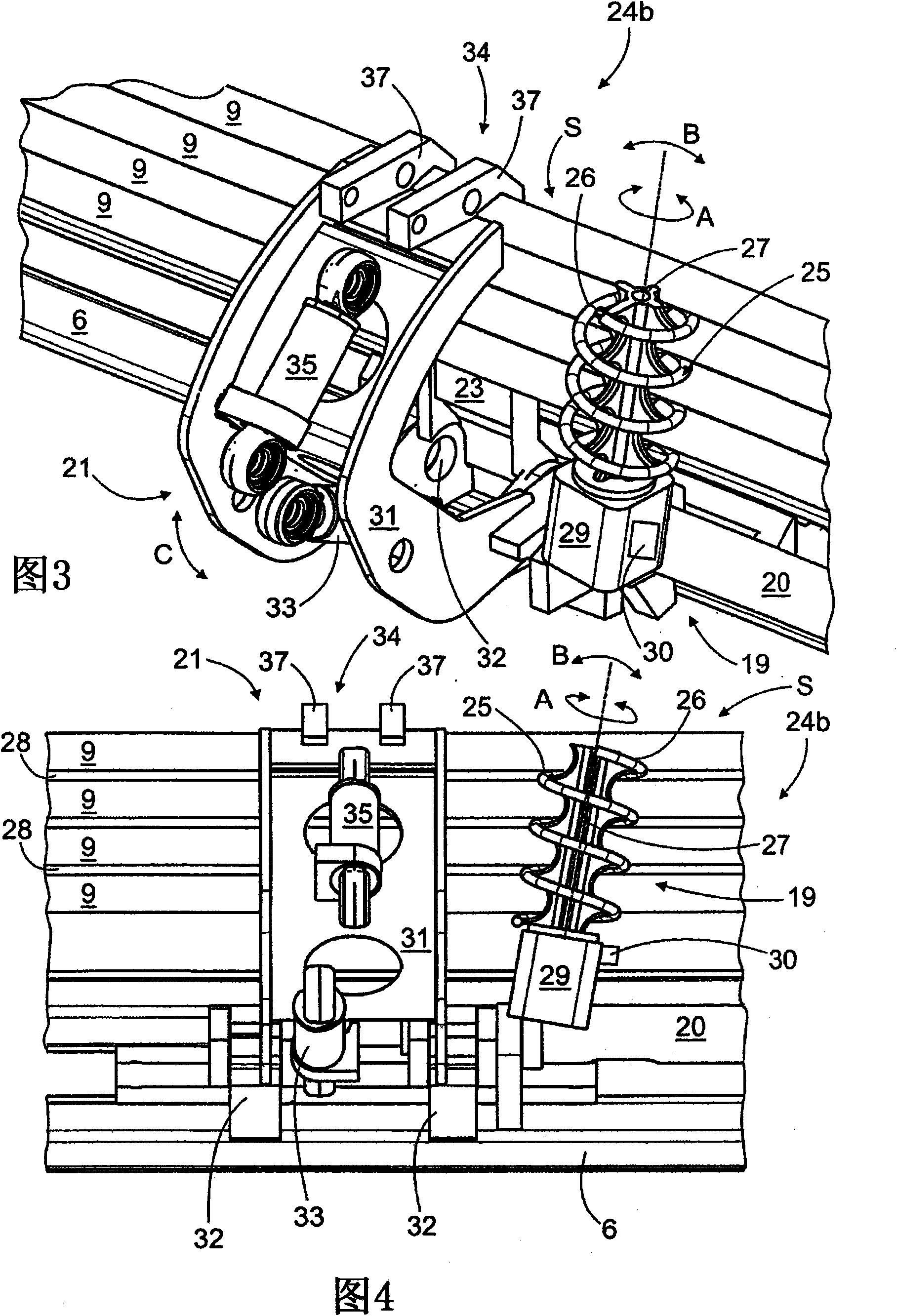

[0043] figure 1 A rock drilling apparatus 1 is shown comprising a movable carrier 2 arranged with one or more drilling arms 3 provided with a rock drilling unit 4 . The rock drilling unit 4 comprises a rock drilling machine 5 movable along a feed beam 6 by means of a feed device 7 . The rock drilling machine 5 may have connected thereto a drilling tool 8 which may comprise a plurality of continuous drilling rods 9 connected to each other by connecting members such as screw joints. Furthermore, the outermost end of the outermost drill rod 9 is provided with a drill bit 10 having a drill button that creates a drill hole 12 into the rock 11 . The rock drilling machine 5 may comprise percussion means for supplying percussion pulses to the drilling tool 8 which transmits percussion pulses to the drill bit 10 and further to the rock 11 to be broken. The rock drilling machine 5 may also comprise rotation means allowing the drilling tool 8 to rotate about its longitudinal axis durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com