Double-sided waterproof insulation quilt

A thermal insulation, double-sided technology, applied in greenhouse cultivation, horticulture, climate change adaptation and other directions, can solve the problems of high cost, non-waterproof surface, disproportionate cost to farmers, etc., to save construction costs, low bearing capacity requirements, and solve The effect of incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

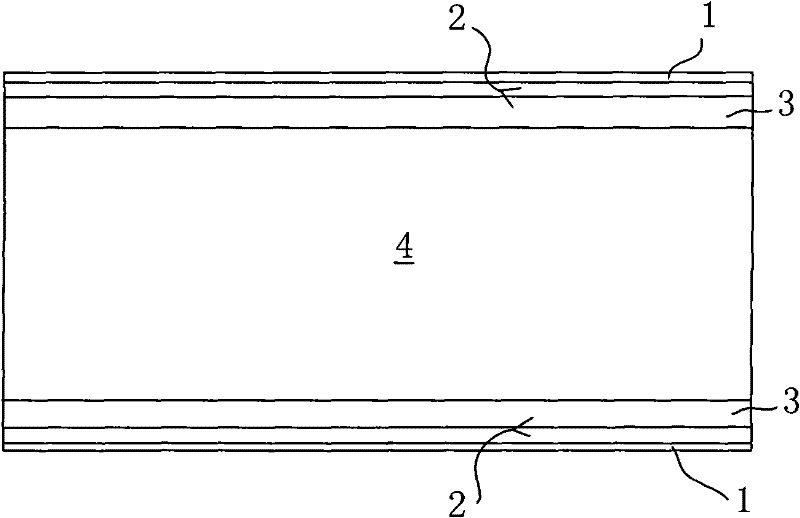

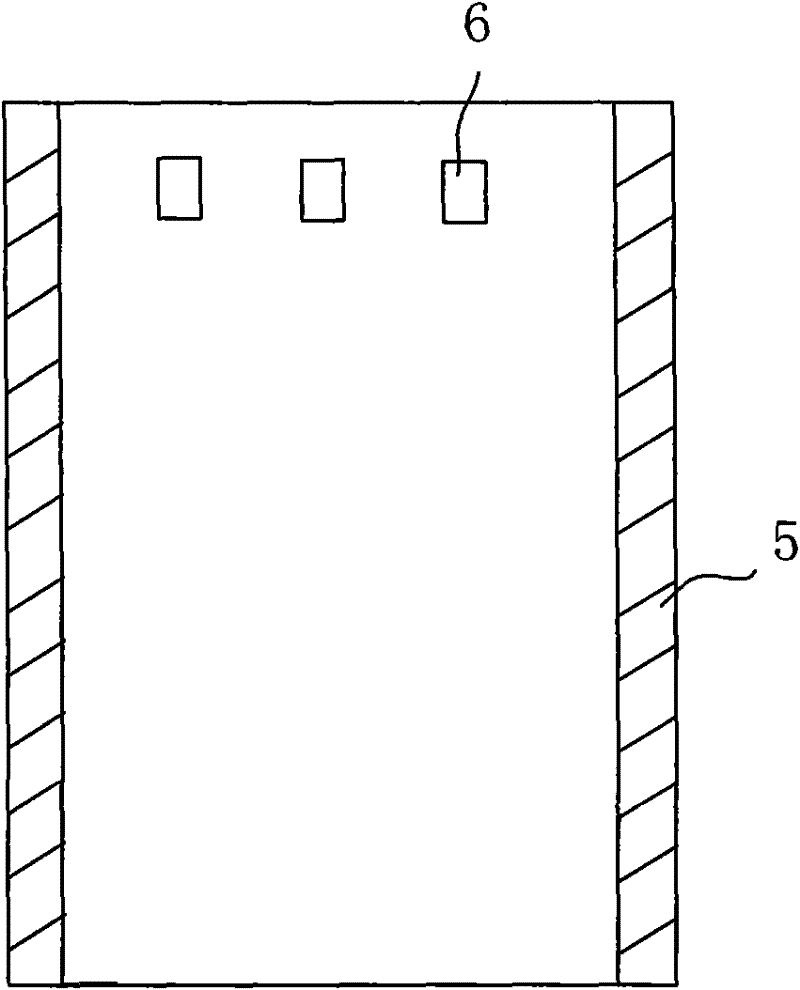

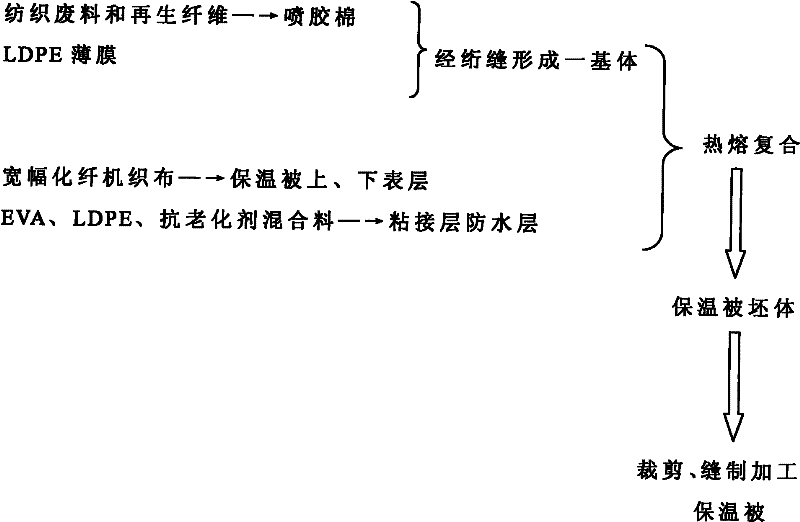

[0022] Such as Figure 1-3 As shown, the key point of the double-sided waterproof solar greenhouse insulation quilt is that the chemical fiber sprayed cotton 4 with a weight of 300-600 grams per square meter is used as the main body of the thermal insulation quilt, and the chemical fiber sprayed cotton 4 is made of polyester, acrylic or nylon. One or several kinds are used as raw materials. In order to reduce costs, the chemical fiber spray-bonded cotton 4 is made of leftovers from textile or garment factories after flowering, carding and mixing with polyester or acrylic fibers and nylon staple fibers. The leftovers are mixed with polyester or acrylic fibers , the mass ratio of nylon staple fiber is 75: 25 parts, utilizes the glue-sprayed cotton processing technology, makes the wide glue-sprayed cotton of 2-3 meters, the upper and lower surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com