Tailing treatment method and system

A treatment method and a treatment system technology, applied in the field of tailings treatment method and its treatment system, can solve the problems that tailings cannot meet the dry stacking conditions and the recovery rate of tailings wastewater is low, so as to achieve compact and reasonable process flow and reduce occupation , Eliminate the effect of dam break

Inactive Publication Date: 2010-12-08

TANGSHAN LUANHE XINFENG MINING

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problems of low recovery rate of tailings wastewater in the prior art and tailings not reaching the dry stacking conditions, the present invention provides a novel tailings treatment method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0034] Embodiment 1 is basically the same as Embodiment 2, except that the angle of the lower cone of the concentration pool is 70 degrees.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Login to View More

Abstract

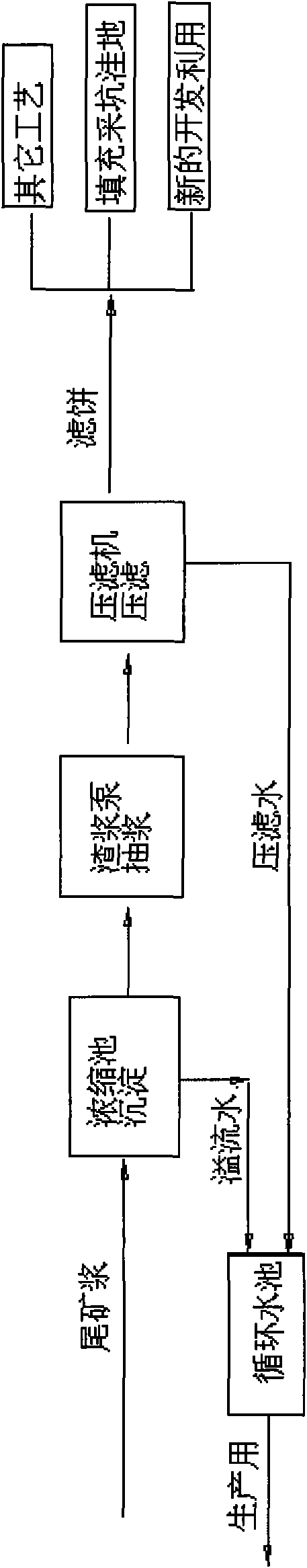

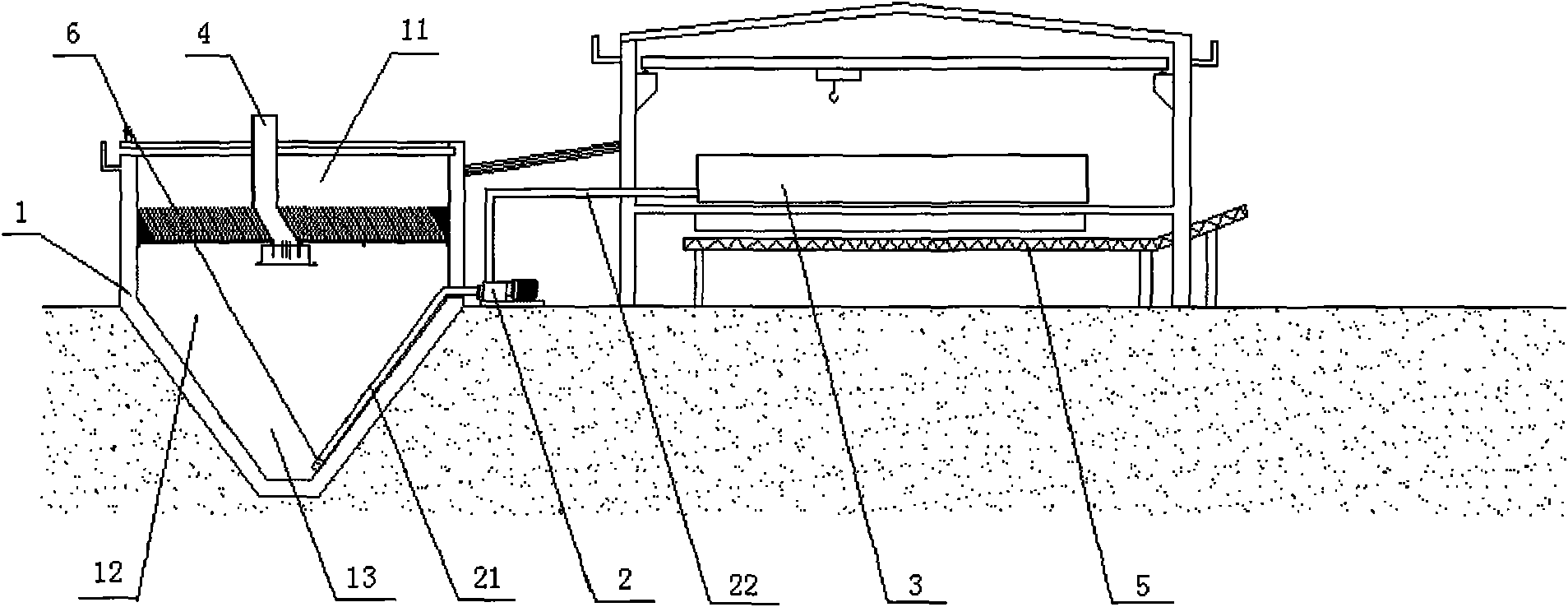

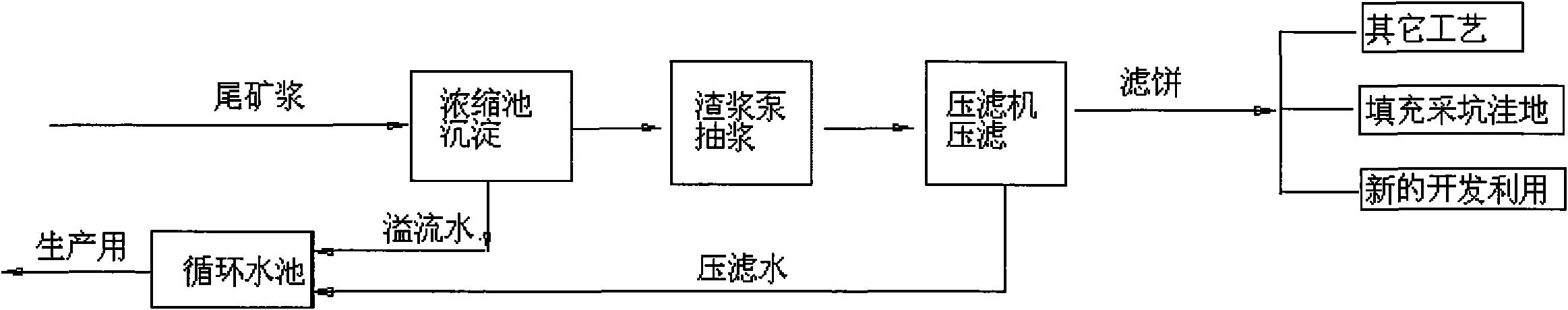

The invention relates to tailing treatment method and system. The tailing treatment method comprises the following steps of: conveying tailing slurry into a thickener to precipitate; recovering overflowing water; drawing underflow slurry in an underflow area of the thickener by a slurry pump through a suction tube; conveying the underflow slurry in a filter press for pressure filtration; recovering pressure filtration water; and obtaining the treated tailings as a filtration cake. The tailing treatment system comprises the thickener, the slurry pump and the filter press, wherein the thickenercomprises a clear water area, a precipitation area and an underflow area, and the slurry pump is arranged outside the thickener, communicated with the underflow area of the thickener through the suction tube, and connected with the filter press through a discharge tube for feeding the filter press. The method of the invention has compact and reasonable process flows, treated tailings can be used for filing a waste mining pit or can be used for new development and utilization as a building material, and the like so as to reduce the occupation of soil resources and eliminate the potential safety hazards, such as tailing dam break, and the like commonly existing in the mining industry.

Description

technical field [0001] The invention relates to a tailings treatment method and a treatment system thereof. Background technique [0002] For a long time, the tailings treatment of metal mine concentrators generally adopts the method of tailings ponds to store tailings. In this kind of tailings treatment project, after a large area of sedimentation tank is used to recover part of the circulating water, the underflow mud with relatively high concentration is still discharged to the tailings pond. Although with the development of technology, some large-scale dehydration equipment is gradually introduced to the mining industry, but there are still some difficulties in use, the degree of dehydration is not high enough, and the treatment of tailings does not meet the requirements of dry stacking, so it is still necessary to build tailings storage. Contents of the invention [0003] In order to solve the above problems in the prior art that the tailings wastewater recovery ra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D36/00B01D36/04B01D21/02B03B9/06

Inventor 陈少春张佐宏

Owner TANGSHAN LUANHE XINFENG MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com