Lens dyeing machine and dyeing method thereof

A dyeing machine and lens technology, which is applied in the field of dyeing machines, can solve the problems of complex operation, time-consuming, heavy color, etc., and achieve the effect of simple and convenient operation, simple and reasonable structure, and good dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

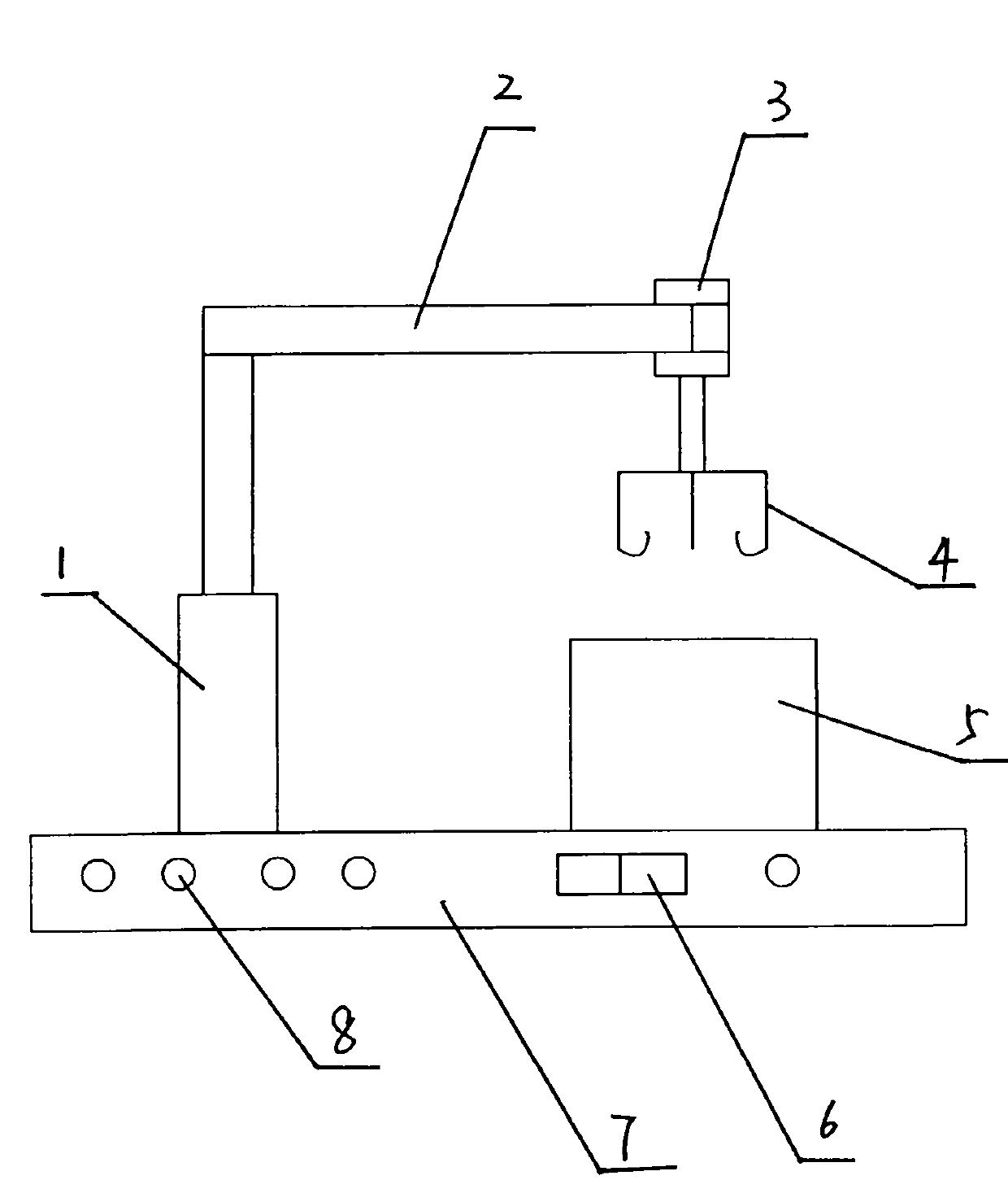

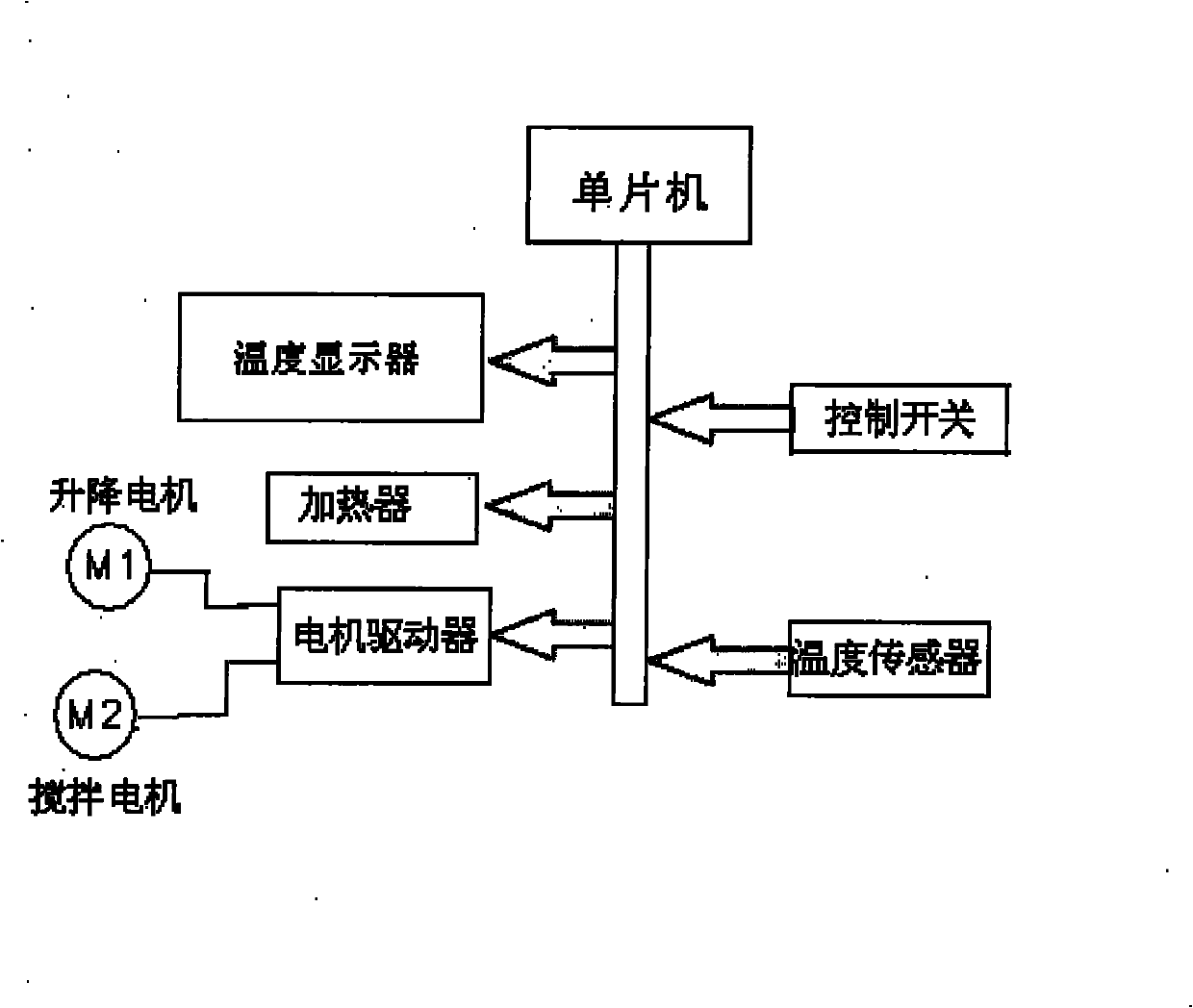

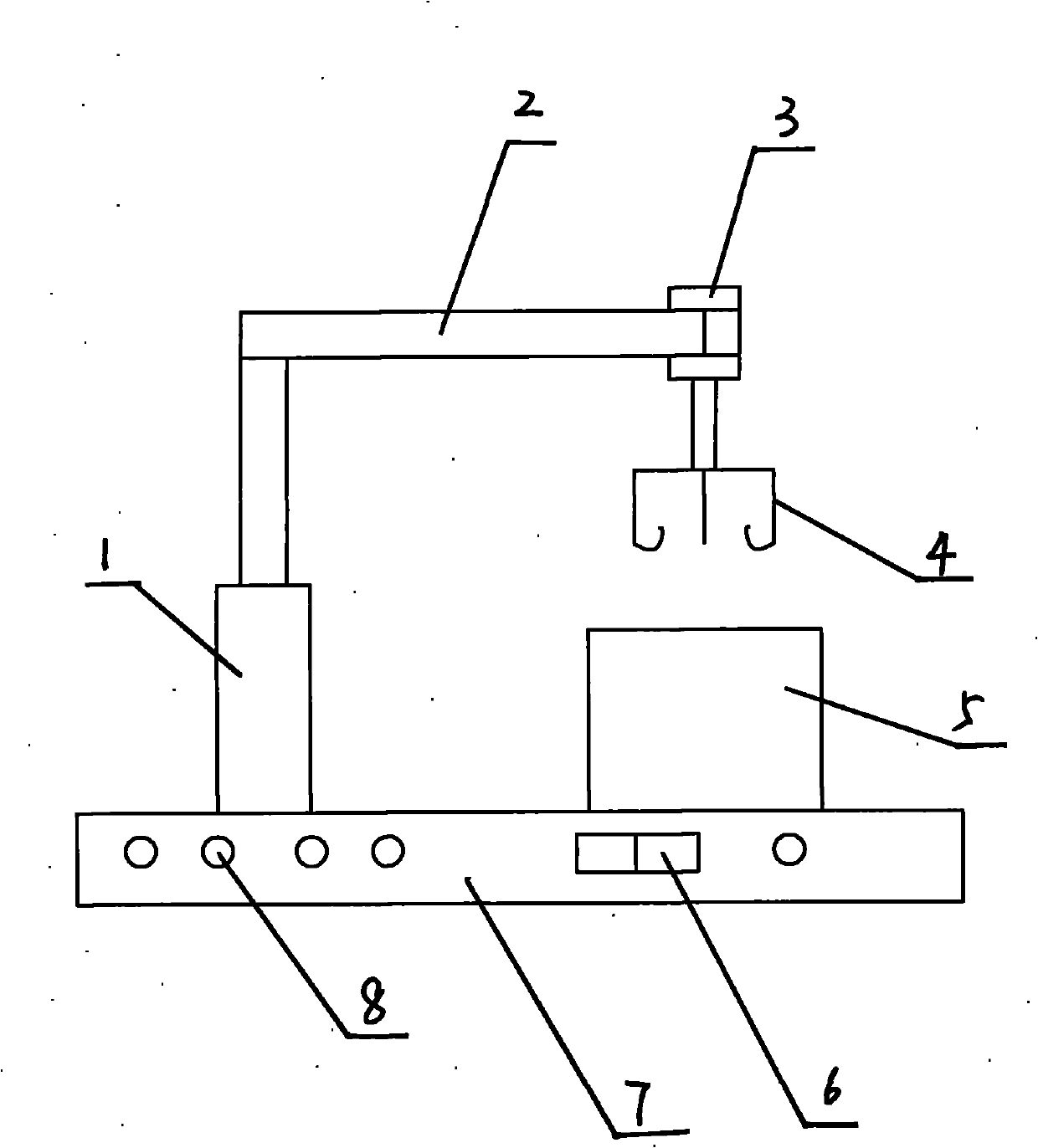

[0019] Example 1. refer to Figure 1-2 . A lens dyeing machine, which comprises a base 7, a control switch 8, a liquid crystal temperature display 6 and a heater are arranged on the base 7, a dyeing solution container 5 is arranged on the heater, and a temperature sensor is arranged on the dyeing solution container 5; 7 is also provided with a lifting frame 2 connected with the lifting motor 1, the lifting frame 2 is provided with a stirring motor 3, and the power output end of the stirring motor 3 is connected with a lens clamping mechanism 4, and the lens clamping mechanism 4 is above the dyeing solution container 5; the lifting motor 1 and the stirring motor 3 are all connected with the motor driver; it is also provided with a single-chip microcomputer for control, the liquid crystal temperature display, the heater, the control switch, the temperature sensor and the motor driver All are connected with the microcontroller.

Embodiment 2

[0020] Example 2. A method for dyeing lenses using the lens dyeing machine described in Embodiment 1, the steps are as follows:

[0021] (1) configure the dyeing solution as required and pour it into the dyeing solution container 5, and the liquid level height is 1 / 3 of the dyeing solution container 5;

[0022] (2) start the heater by the control switch 8, heat the dyeing solution container 5, detect the temperature of the dyeing solution in the dyeing solution container 5 by the temperature sensor, and keep the temperature of the dyeing solution between 40 ℃;

[0023] (3) Start the elevating motor 1 to raise the elevating frame 2, clamp the lens to be dyed on the lens clamping mechanism 4, then lower the elevating frame 2, immerse the lens in the dyeing solution to the required height, and carry out full dyeing, half dyeing Dyeing or gradient dyeing; when dyeing, start the stirring motor 4 to drive the lens to rotate in the dyeing solution, and the dyeing time is 3 minutes; ...

Embodiment 3

[0025] Example 3. A method for dyeing lenses using the lens dyeing machine described in Embodiment 1, the steps are as follows:

[0026] (1) configure the dyeing solution as required and pour it into the dyeing solution container 5, and the liquid level height is 3 / 4 of the dyeing solution container 5;

[0027] (2) start the heater by the control switch 8, heat the dyeing solution container 5, detect the temperature of the dyeing solution in the dyeing solution container 5 by the temperature sensor, and keep the temperature of the dyeing solution between 80 °C;

[0028] (3) Start the elevating motor 1 to raise the elevating frame 2, clamp the lens to be dyed on the lens clamping mechanism 4, then lower the elevating frame 2, immerse the lens in the dyeing solution to the required height, and carry out full dyeing, half dyeing Dyeing or gradient dyeing; when dyeing, start the stirring motor 4 to drive the lens to rotate in the dyeing solution, and the dyeing time is 8 minutes;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap