Net hauling machine

A technology of netting machine and frame, applied in fishing boats and other directions, can solve the problems of wear and tear of ropes, easy accidents, high pressure, etc., and achieve the effects of saving use costs, reducing labor intensity and large contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

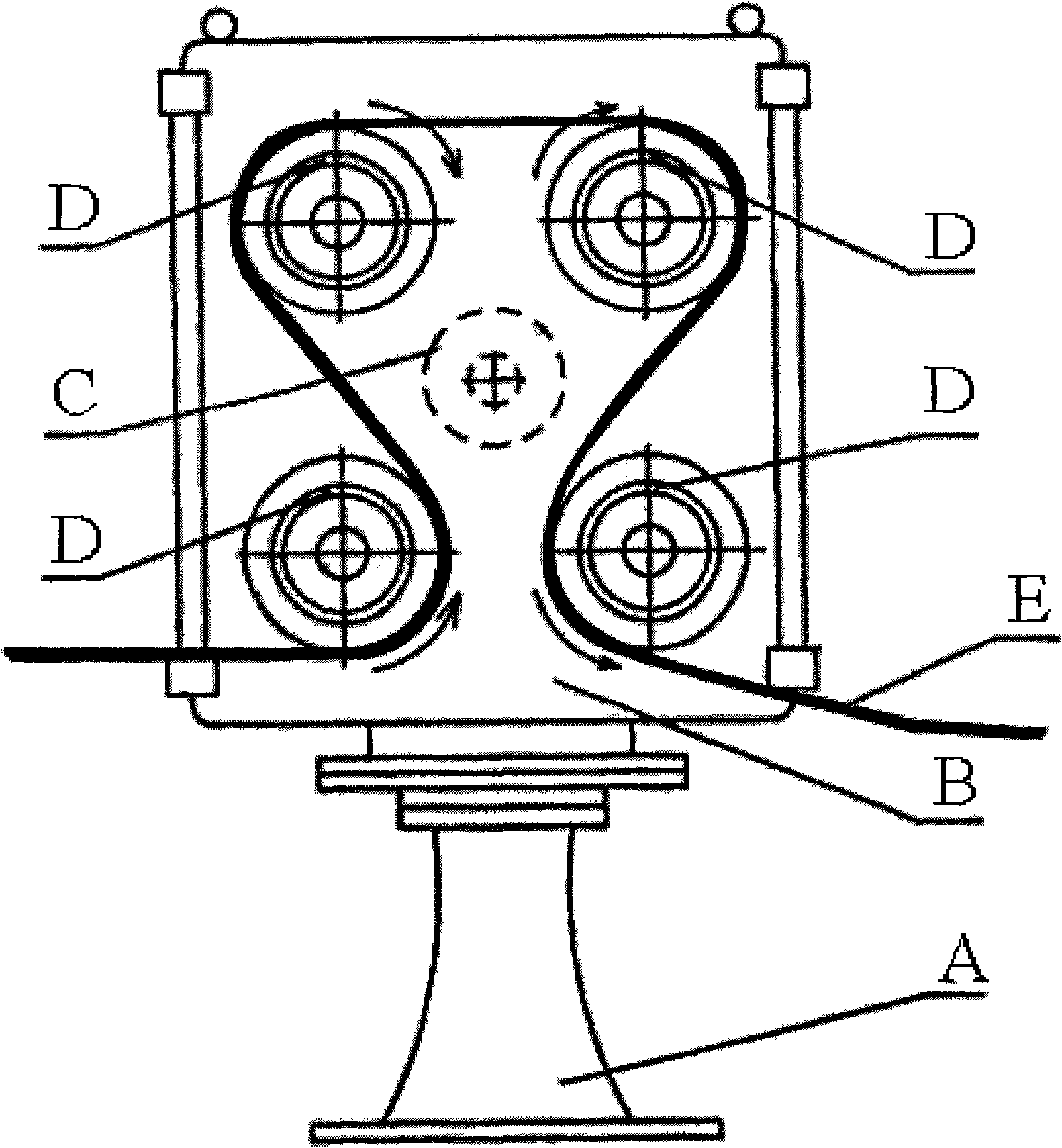

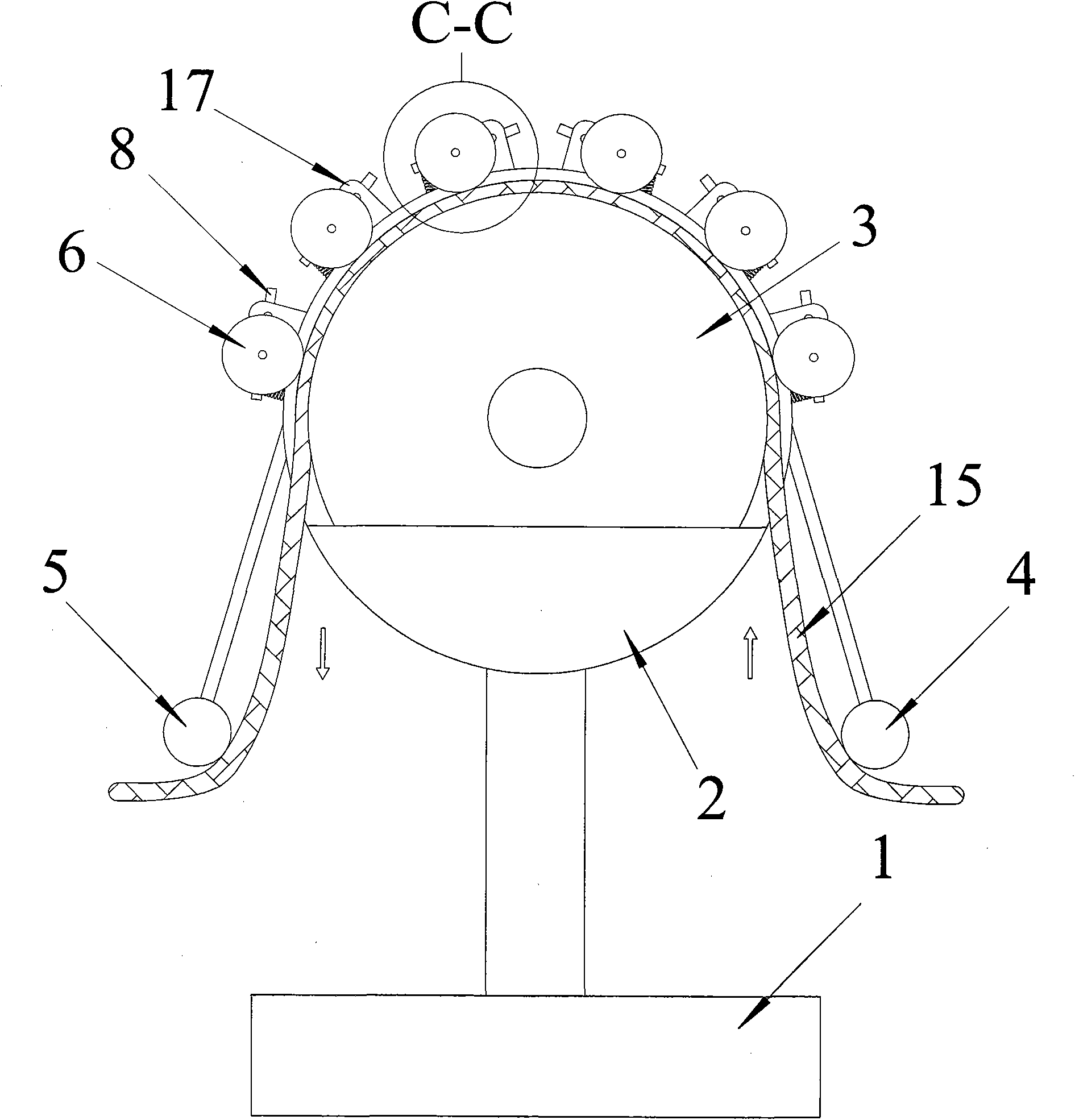

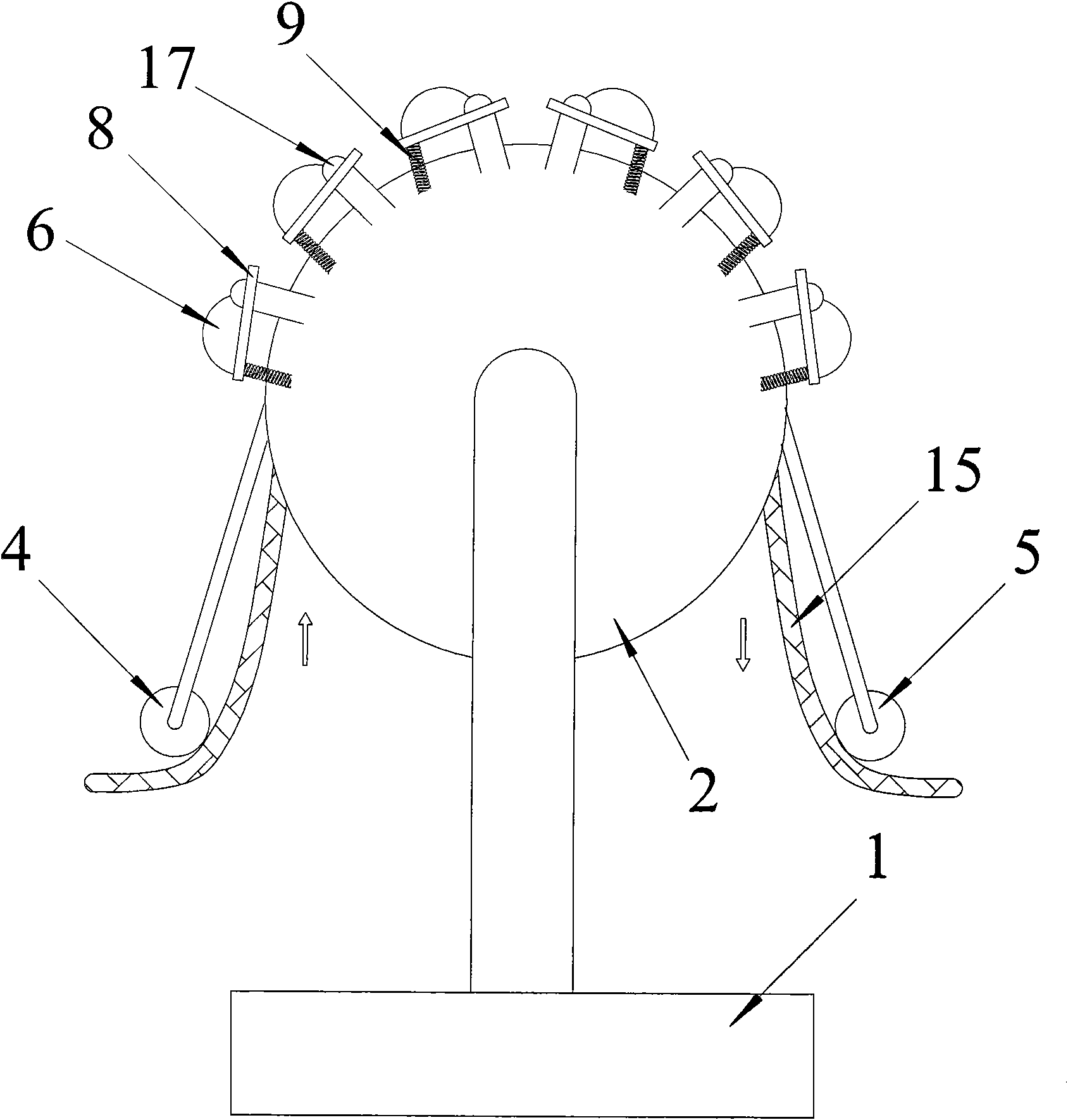

[0022] Such as figure 2 , image 3 , Figure 4 Shown, the present invention comprises frame 1, traction wheel 3, positioning wheel 4,5 and pressure wheel mechanism, and frame 1 side installs traction wheel 3, and traction wheel 3 is driven to rotate by the power unit installed in frame 1, A positioning wheel 4,5 is respectively set on both sides below the traction wheel, and the pinch wheel 6 on the pinch wheel mechanism is pressed on the traction wheel 3 . During work, the key line 15 of described fishing net walks around from one positioning wheel 4 to the traction wheel 3 top and then passes through another positioning wheel 5 below, and the pinch wheel 6 is pressed on the key line. Because the effect of pinch roller 6 makes key line 15 stick on the upper circumferential surface of traction wheel 3, key line 15 and traction wheel 3 contact area are big and produce enough frictional force, the phenomenon of traction wheel 3 idling and skidding can not take place. No need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com