Radiation heating furnace with external circulating device

A technology of radiation heating and external circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

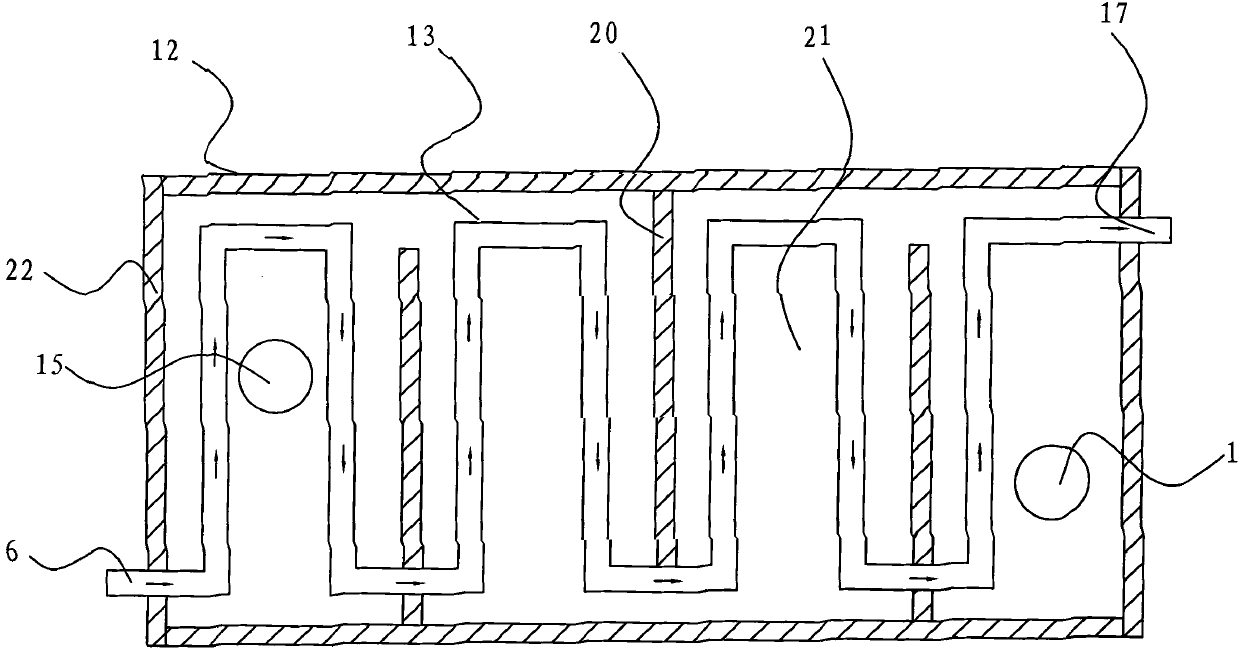

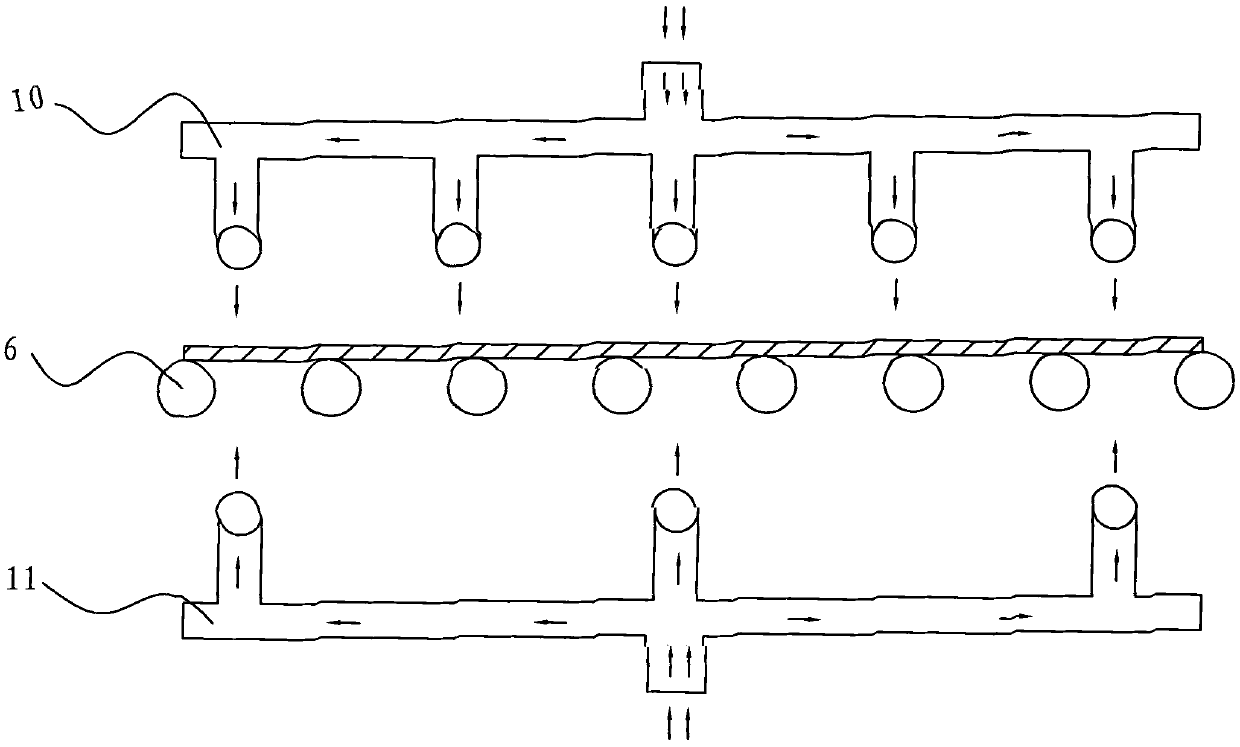

[0026] Such as figure 1 As shown, a radiation heating furnace with an extracorporeal circulation device includes a furnace body 1 and an extracorporeal circulation device located outside the furnace body 1. The furnace body 1 consists of a liftable upper furnace body 2 and a lower furnace body 3 fixed on the ground. The upper furnace body 2 and the lower furnace body 3 are respectively provided with an upper heating unit 4 and a lower heating unit 5, and a transmission roller table 6 for conveying LOW-E glass is arranged between the upper heating unit 4 and the lower heating unit 5; The circulation device includes a hot air compressor 18, an air storage tank 19, a heat exchanger 7, an induced draft fan 8, an air suction pipe 9, an upper air injection pipe 10, a lower air injection pipe 11 and connecting pipelines;

[0027] The heat exchanger 7 includes an inner chamber 12 and a heat exchange element 13 arranged in the inner chamber 12, the air inlet 14 of the inner chamber 12 ...

Embodiment 2

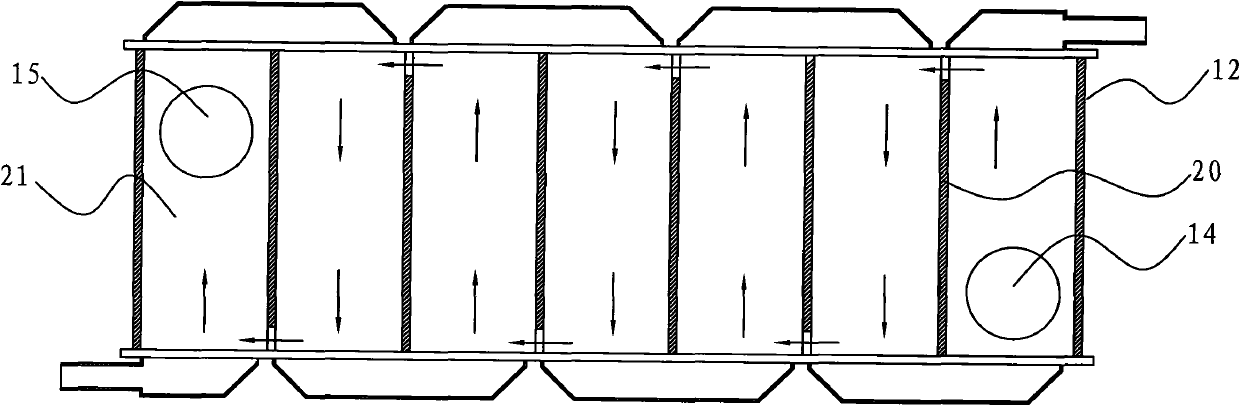

[0034] The heat exchanger in the radiation heating furnace with extracorporeal circulation device of the present invention can also be another structural device.

[0035] Such as Figure 5 As shown, the inner wall of the heat exchanger 7 is closely attached to an insulation layer 22, so as to reduce the heat loss of the gas inside the heat exchanger 7;

[0036] The heat exchanger 7 includes an inner cavity 12 and a heat exchange element 13 arranged in the inner cavity 12, the air inlet 14 of the inner cavity 12 communicates with the suction pipe 9 inserted into the upper furnace body 2, and the air outlet 15 of the inner cavity 12 It communicates with the induced draft fan 8; the air intake pipe 16 of the heat exchange element 13 communicates with the air storage tank 19, and the air outlet pipe 17 of the heat exchange element 13 communicates with the upper gas injection pipe 10 inserted into the upper furnace body 2;

[0037] Such as Figure 6 As shown, the inner cavity 12 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com