Quenching and temperingTempering heat treatment process for different-alloy high-chromium cast iron blow bars

A technology of quenching and tempering heat treatment and high-chromium cast iron, applied in the field of heat treatment of blow bars, can solve the problems of being unsuitable for excessive use and expensive, and achieve the effect of improving toughness and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The 1212 impact crusher of a crushing plant in Tongliao, the crushed stone is limestone, which is soft and has little impact. We design a blow bar with the following composition (wt%):

[0025] C Si Mn Cr Mo Cu P S Re

[0026] 3.40 0.38 0.96 15.50 0.51 0.86 ≤0.05 ≤0.04 0.2

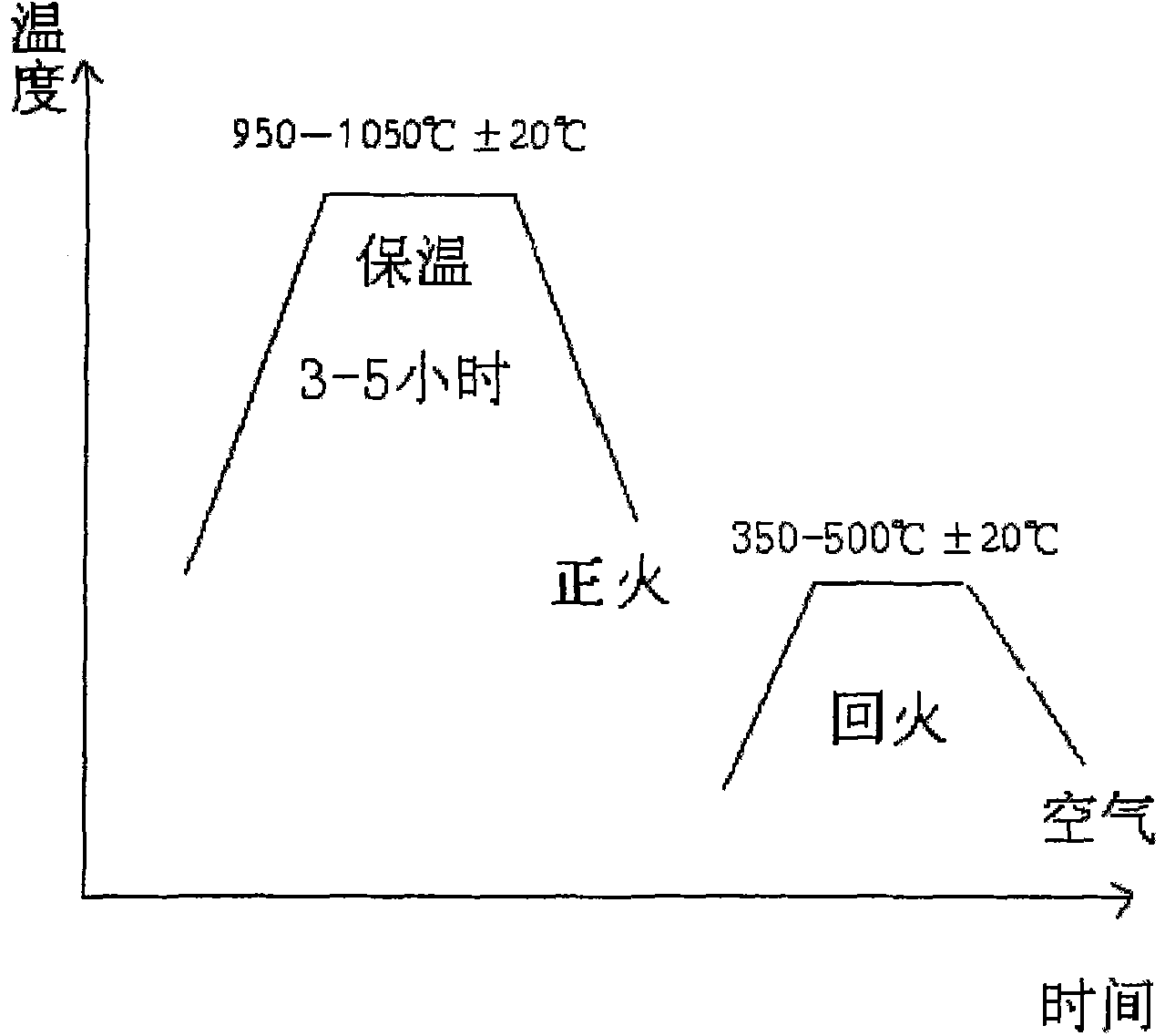

[0027] Heat the blow bar with the above alloy composition in a high-temperature electric furnace at 30°C / hour to 500°C (low temperature section), and then heat it to 950°C at a heating rate of 50°C / hour, and keep it warm for 4 hours. The temperature error is controlled as ±20°C, then quickly air-cooled and normalized under the direct blowing of the fan, and then tempered the blow bar after normalizing in a high-temperature tempering furnace at 350°C for 5 hours. The atmosphere is air;

[0028] After the quenched and tempered blow bar was used by Tongliao Crushing Plant for 3 months, the powdered limestone was 50,000 cubic meters, and the user was very satisfied. Compared with other blow bars with ...

Embodiment 2

[0030] In the Xinglong Crushing Plant in Chaoyang area, the 1414 impact crusher is also used to crush limestone. The input particle size is large, so the impact is relatively large. We have adjusted the strength and toughness, and the effect is very good. The composition is as follows (wt%):

[0031] C Si Mn Cr Mo Cu Ti V P S Re

[0032] 2.85 0.42 1.06 16.58 0.52 0.90 0.08 0.12 0.04 0.035 0.2

[0033] Heat the blow bar with the above alloy composition in a high-temperature electric furnace at 45°C / hour to 500°C (low temperature section), then heat to 1000°C at a heating rate of 70°C / hour, and keep it warm for 5 hours. The temperature error is controlled as ±20°C, and then quickly air-cooled and normalized under the direct blowing of a strong fan. In summer, it should be properly sprayed, and then the normalized blow bar should be tempered at 450°C for 4 hours in a high-temperature tempering furnace. The temperature is controlled at ±20°C, and the tempering atmosphere is air; ...

Embodiment 3

[0036] Inner Mongolia Jalut Banner Hongguang Crushed Stone Plant, 1070 counterattack broken, crushed granite, the stone is relatively hard, the particle size of the input material is not large, and the impact is small. We adjusted the composition structure and carried out the quenching and tempering treatment of the present invention. After the second test, we obtained Better effect, improve wear resistance 38% on the original basis, final determination composition is as follows (wt%):

[0037] C Si Mn Cr Mo Cu Ni Nd Re P S

[0038] 3.08 0.52 0.85 17.32 1.23 0.50 0.61 0.2 0.2 0.032 0.035

[0039] Heat the blow bar with the above alloy composition in a high-temperature electric furnace at 40°C / hour to 500°C (low temperature section), then heat at a heating rate of 80°C / hour to a temperature of 1050°C and keep it for 4 hours. The temperature error is controlled to ± 20°C, quickly air-cooled and normalized under the direct blowing of a strong fan, and then tempered the blow bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com