High-temperature axial-flow type tail gas turbine

An exhaust turbine and axial flow technology, which is applied in non-variable engines, leakage prevention, blade support components, etc., can solve the problems of high-speed turbines that cannot use medium with solid particles, blade tip air leakage loss, and strength margins. In order to reduce deformation, reduce air leakage loss and improve thermal insulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

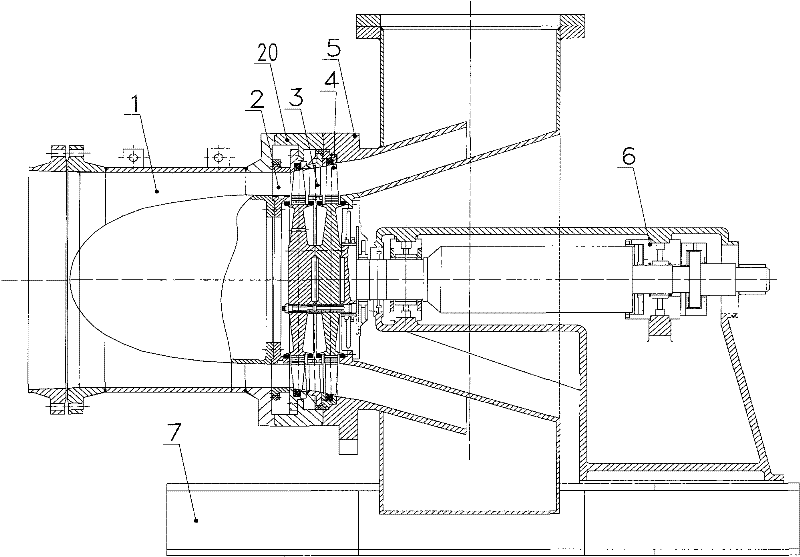

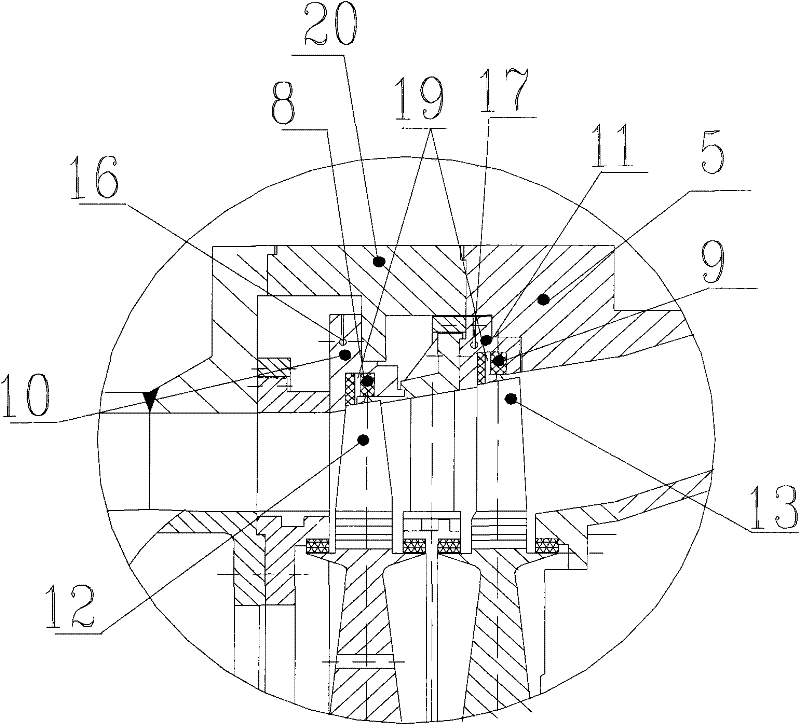

[0026] Such as figure 2 , image 3 with Figure 4 As shown, a high-temperature axial-flow exhaust gas turbine adopts the structural form of axial intake and radial upward or downward exhaust, including an intake casing 1, a first-stage guide vane 2, a second-stage guide vane 3, Rotor 4, transition housing [20], exhaust casing 5, bearing system 6 and base 7.

[0027] Moving blades are installed on the rotor 4;

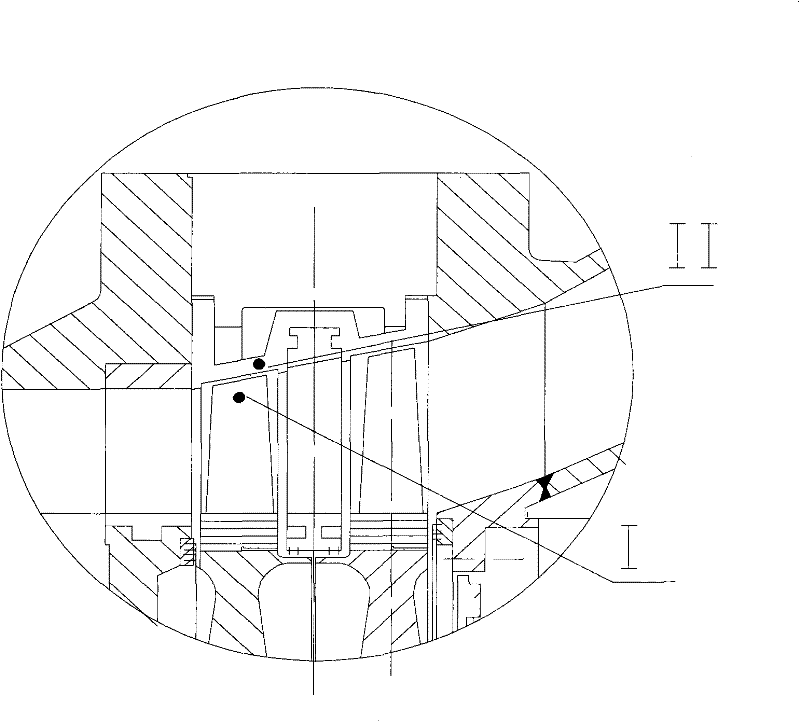

[0028] Each blade of the moving blade includes a crown 14, a blade body [18] and a blade root 15; each crown 14 is a V-shaped structure.

[0029] The moving blades include primary moving blades 12 and secondary moving blades 13 .

[0030] The blade tip shroud of the moving blade adopts a honeycomb seal of the whole ring structure, specifically, the first-level moving blade honeycomb seal 8 is on the outside of the first-level moving blade 12, and the second-level moving blade honeycomb seal is on the outside of the second-level moving blade 13. Leaf honeycomb seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com