Novel balanced type water inlet and outlet valve group of ultrahigh pressure supercharger

A technology of ultra-high pressure and supercharger, which is applied in the direction of machines/engines, variable displacement pump components, pump components, etc. It can solve the problems of less than 2000 hours, material fatigue damage and working life, and reduce the manufacturing process and material requirements. , Reduce system pressure fluctuations, large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Such as Figure 2-3 shown.

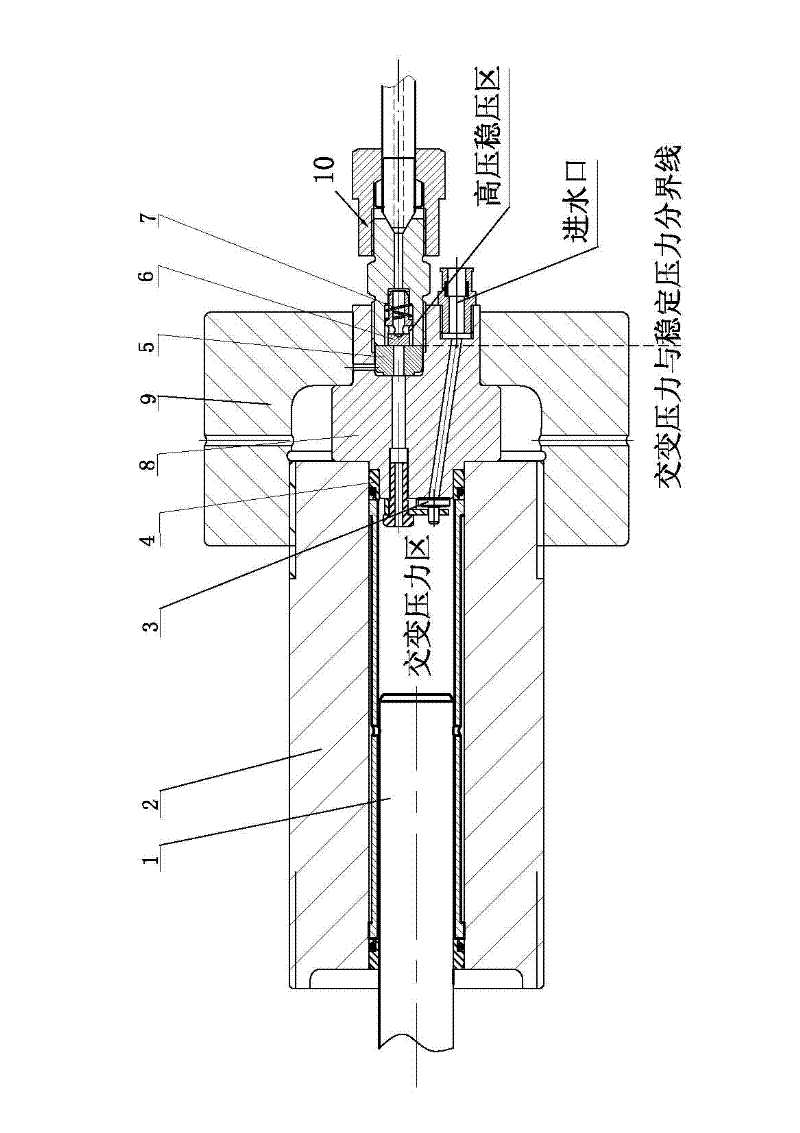

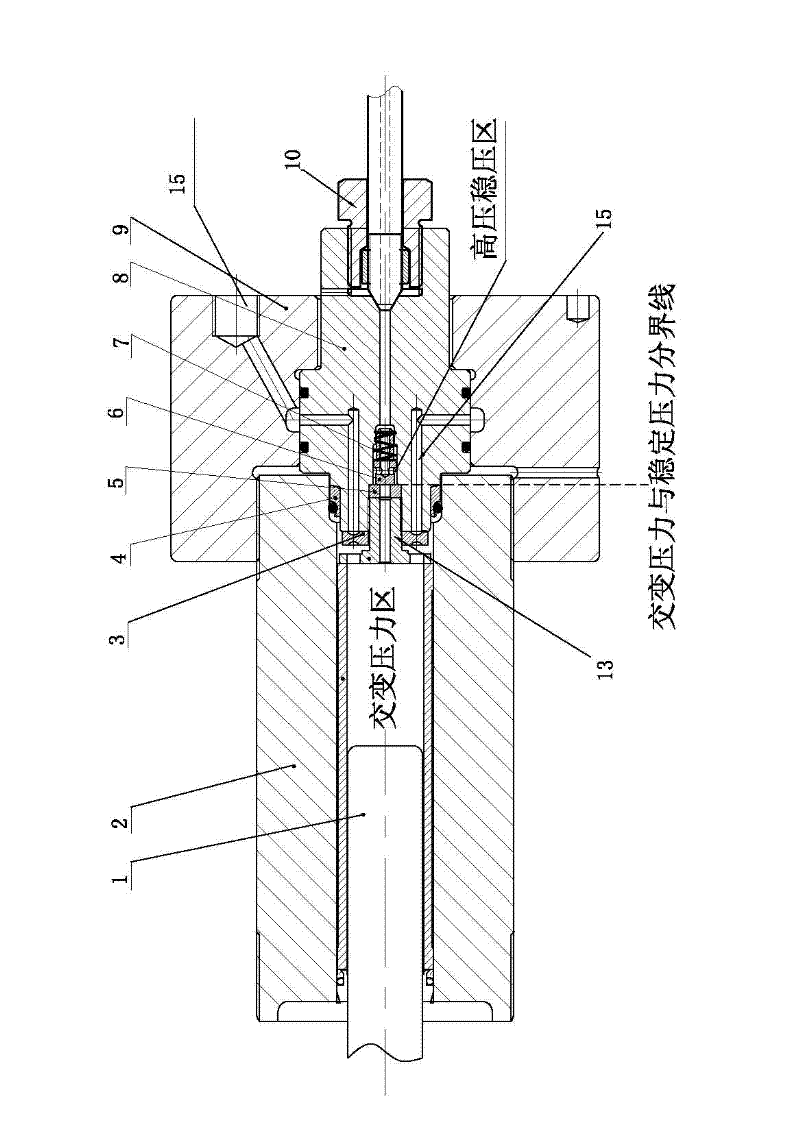

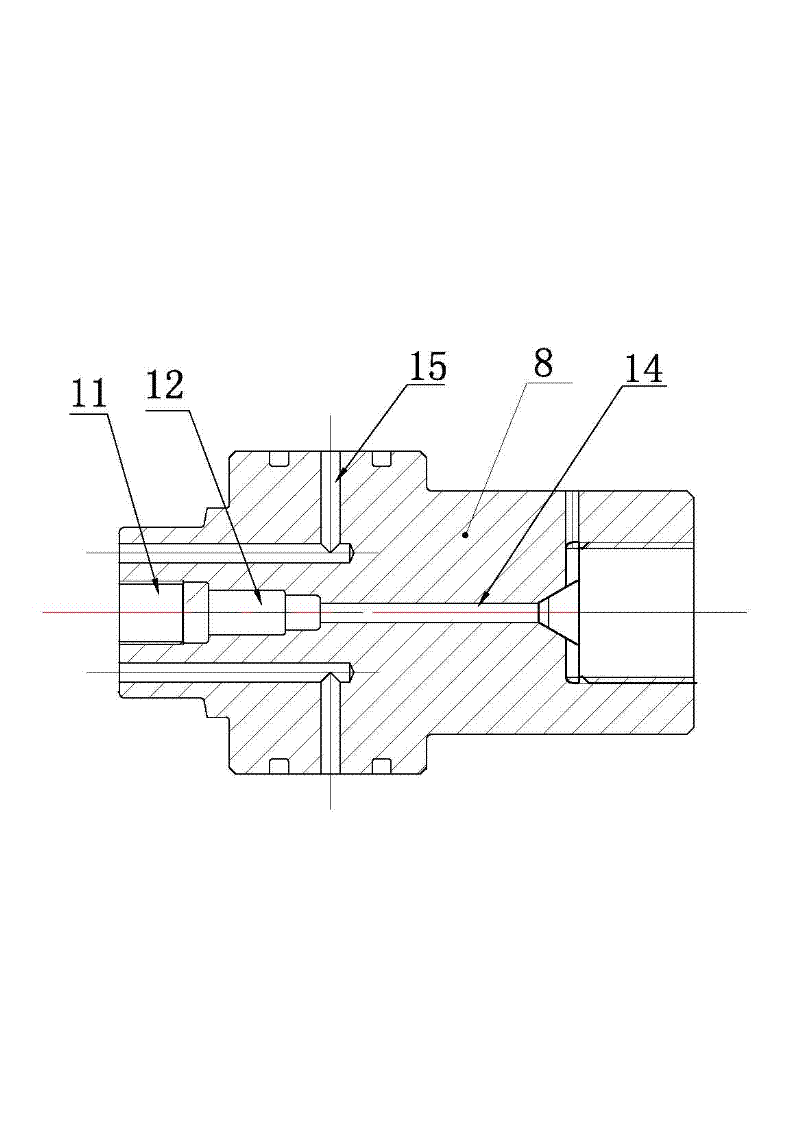

[0021] A balanced ultra-high pressure supercharger intake and discharge valve group, including an end cover 9 and a long plug 8, the end cover 9 is installed on the high pressure cylinder 2, the long plug 8 is installed in the end cover 9; one end of the long plug 8 extends into the In the high-pressure cylinder 2, the other end protrudes from the end cover 9, and one end of the long plug 8 protruding from the end cover 9 is connected with a high-pressure water output joint 10, and the end of the long plug 8 protruding into the high-pressure cylinder 2 is provided with a Install the internal thread mounting hole 11 of the high pressure check valve seat 5, and one side of the internal thread mounting hole 11 is provided with the small diameter mounting hole 12 of the high pressure check valve core 6 installed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com