High-temperature high-pressure clamp for testing rock core by nuclear magnetic resonance

A nuclear magnetic resonance, high temperature and high pressure technology, which is applied in the field of high temperature and high pressure holders and nuclear magnetic resonance gradient core analyzers, can solve the problems that the core cannot be imitated, the actual situation of the core cannot be truly reflected, and the working pressure is low, so as to improve the temperature resistance Withstand pressure performance, improve the overall signal-to-noise ratio, and increase the effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Taking a high temperature and high pressure holder for nuclear magnetic resonance test rock core as an example, the present invention will be further described in detail.

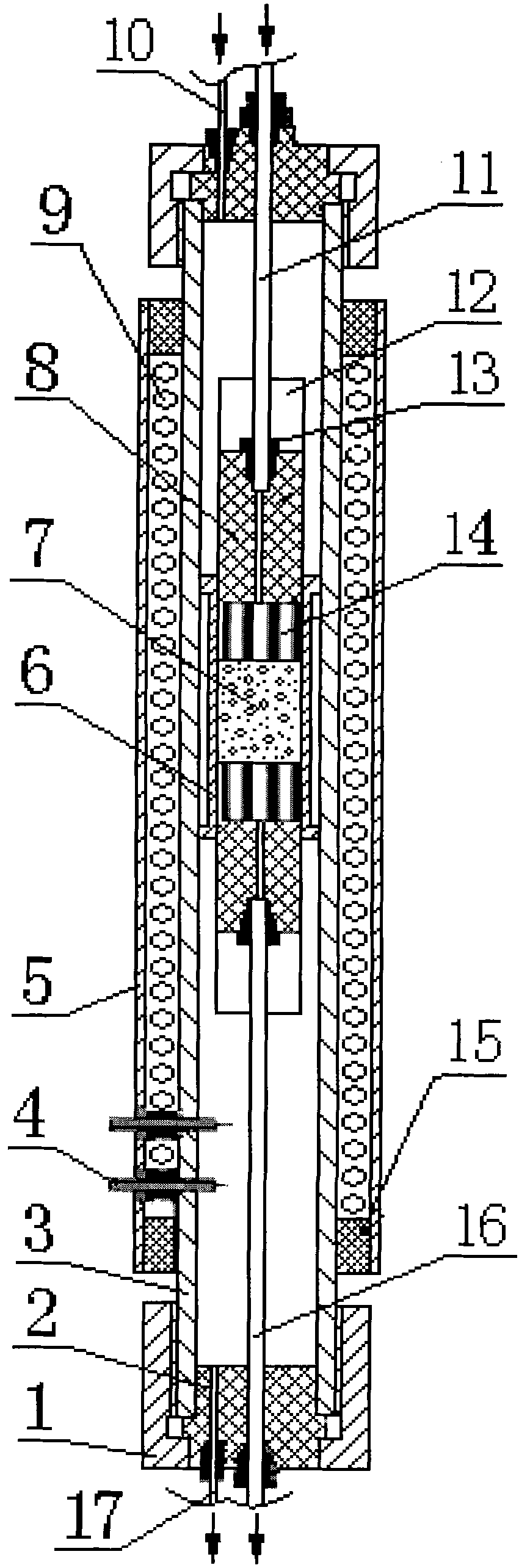

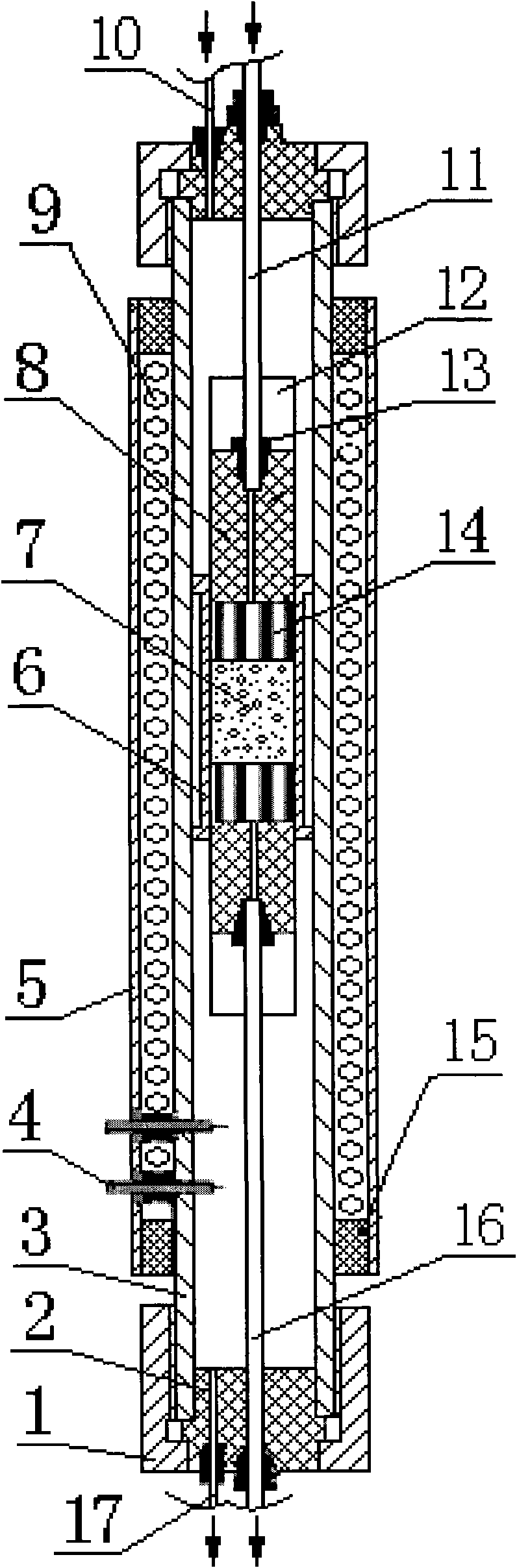

[0031] refer to figure 1 . The high-temperature and high-pressure clamper used for nuclear magnetic resonance testing rock cores of the present invention is composed of a ring pressure part, a high-temperature heating part, a displacement part, and a nuclear magnetic resonance transmitting and receiving coil part.

[0032] 1) ring pressure part

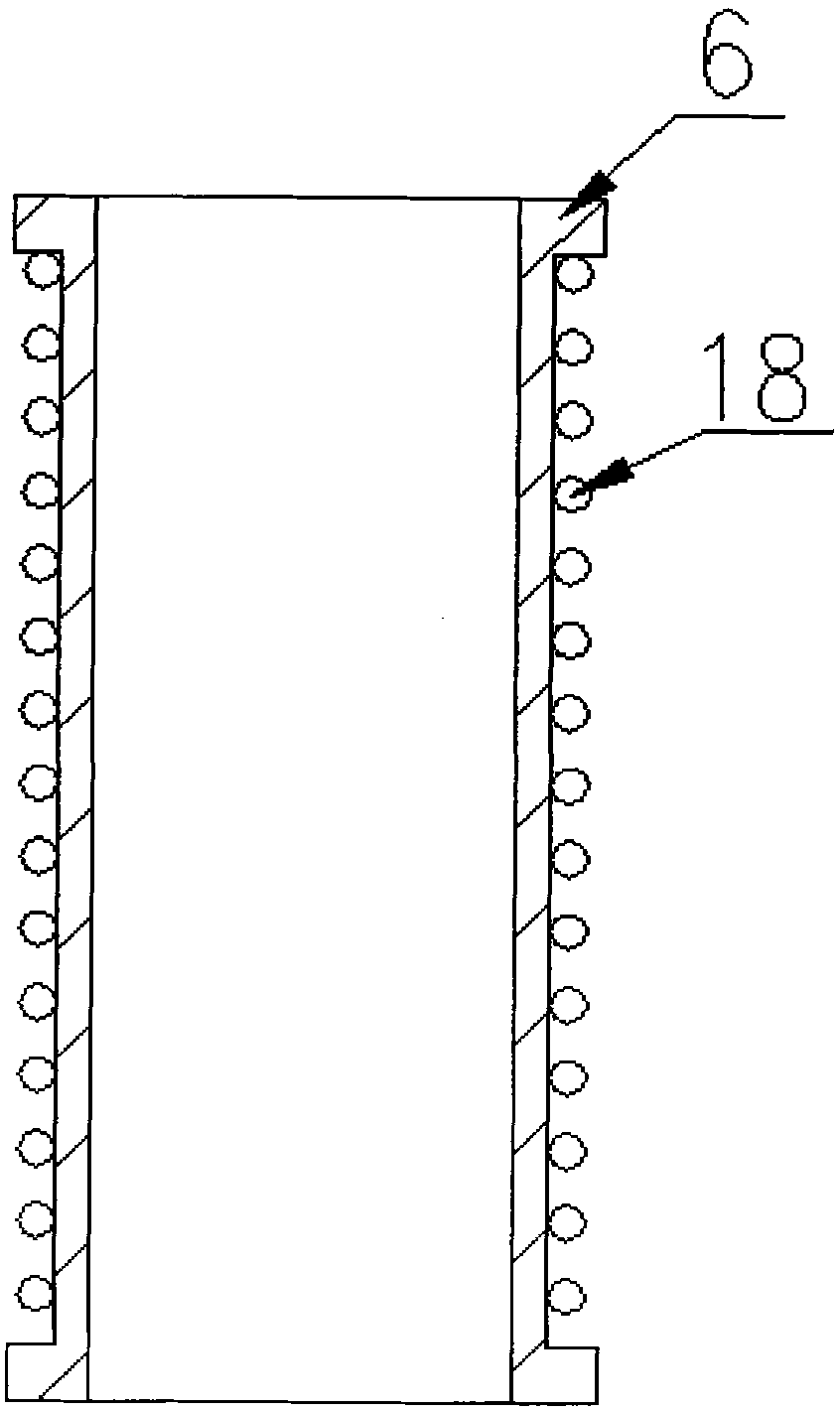

[0033] The ring pressure part is composed of a lock nut 1 , a sealing end cover 2 and a holder cavity 3 . The holder cavity 3 is cylindrical, and the holder cavity 3 is made of aluminum alloy (LY12), with an inner diameter of 60mm, an outer diameter of 74mm, a length of 900mm, and a pressure resistance of 140MPa. The two ends of the holder cavity 3 are covered with sealing end caps 2 respectively; the two ends of the holder cavity 3 are resp...

Embodiment 2

[0041] Embodiment 2: see figure 1 . Embodiment 2 is basically the same as Embodiment 1, except that the lock nut 1 is made of brass; the holder cavity 3 is made of titanium alloy; the heat preservation shell 5 is made of non-magnetic stainless steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com