Optical element gravity deformation draught head compensating device in projection objective system and method thereof

A technology of optical elements and projection objective lenses, which is applied in optical elements, exposure devices for photographic plate-making processes, optics, etc., can solve problems such as high manufacturing costs, difficult installation and debugging of optical element gravity compensation devices, and inability to realize compensation in the central area of optical elements. To achieve the effect of guaranteed optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

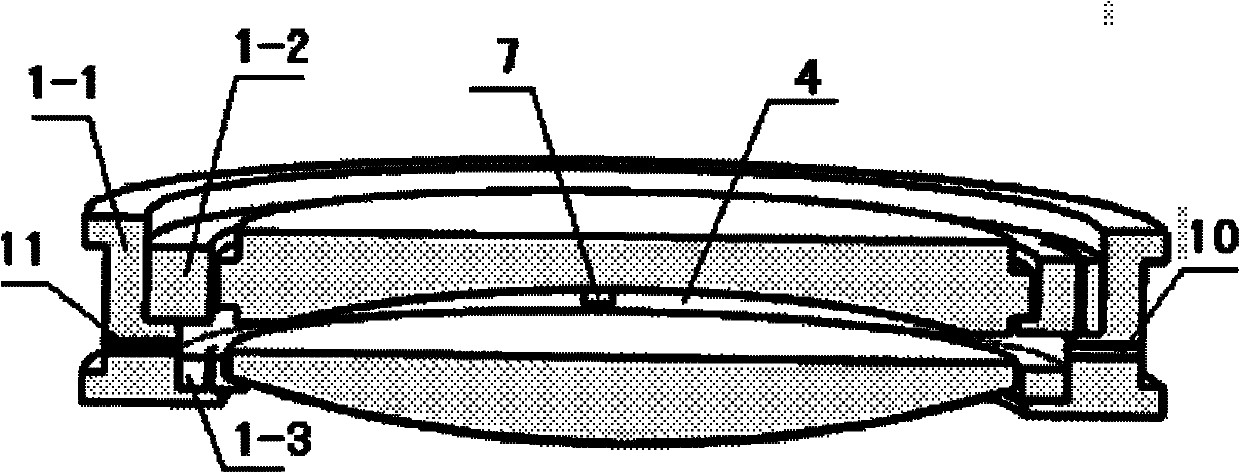

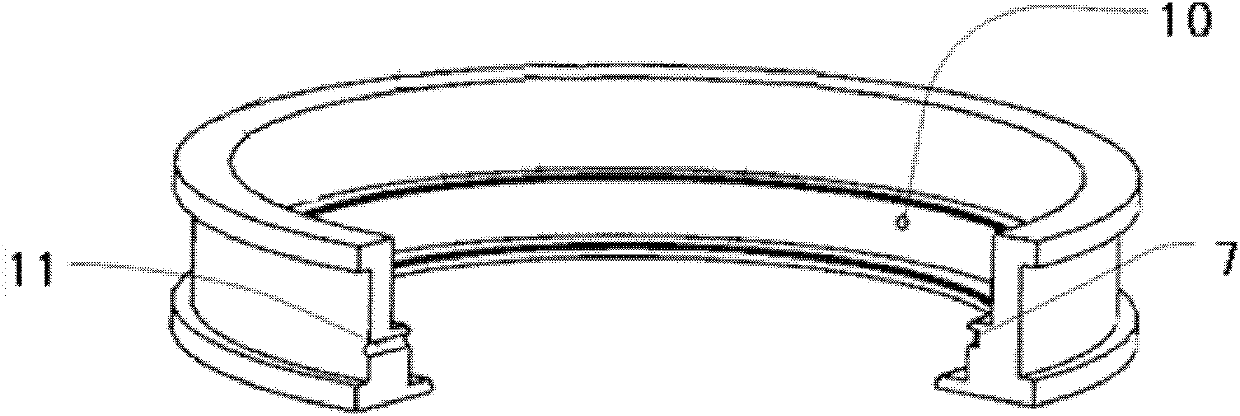

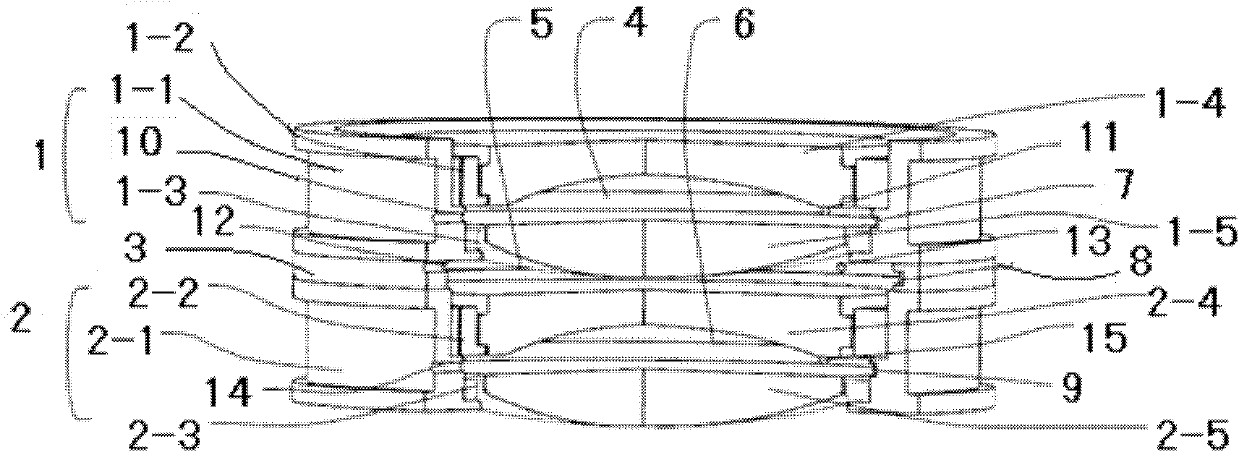

[0030] Specific implementation mode 1. Combination Figure 1 to Figure 8Describe this embodiment, the optical element gravity deformation air pressure difference compensation device in the projection objective lens system is characterized in that it includes a first lens barrel unit assembly 1, a second lens barrel unit assembly 2, a spacer ring 3, and a first gas pressure sensor 7 , a second gas pressure sensor 8 and a third gas pressure sensor 9; a spacer 3 is arranged between the first lens barrel unit assembly 1 and the second lens barrel unit assembly 2;

[0031] The first lens barrel unit assembly 1 includes a first lens barrel unit 1-1, a first lens frame unit 1-2, a second lens frame unit 1-3, a first optical element 1-4 and a second optical element 1-5 The first lens barrel unit 1-1 is a ring structure; the first lens frame unit 1-2 and the second lens frame unit 1-3 are sequentially installed in the first lens barrel unit 1-1; the first optical element 1 -4 and the ...

specific Embodiment approach 2

[0039] Specific implementation mode two, the present implementation mode is the method for the gravity deformation air pressure difference compensation of the optical element in the projection objective lens system, the concrete steps of this method are:

[0040] Step 1, the first gas pressure sensor 7, the second gas pressure sensor 8 and the third gas pressure sensor 9 measure the air pressure in the first sealed chamber 4, the second sealed chamber 5 and the third sealed chamber 6 respectively, and three The air pressure value in the sealed chamber is input to the main controller through the data acquisition card;

[0041] Step 2: The air pressure value obtained by the main controller according to step 1 is compared with the predetermined air pressure value; if each gas pressure sensor detects that the gas pressure value in the sealed cavity does not reach or exceed the predetermined air pressure value, then adjust the gas supply pipeline and exhaust In the working state of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com