Printed circuit board

A printed circuit board, cross-slot technology, applied in the direction of printed circuit, printed circuit, printed circuit components, etc., can solve the problem of increasing the cost of printed circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

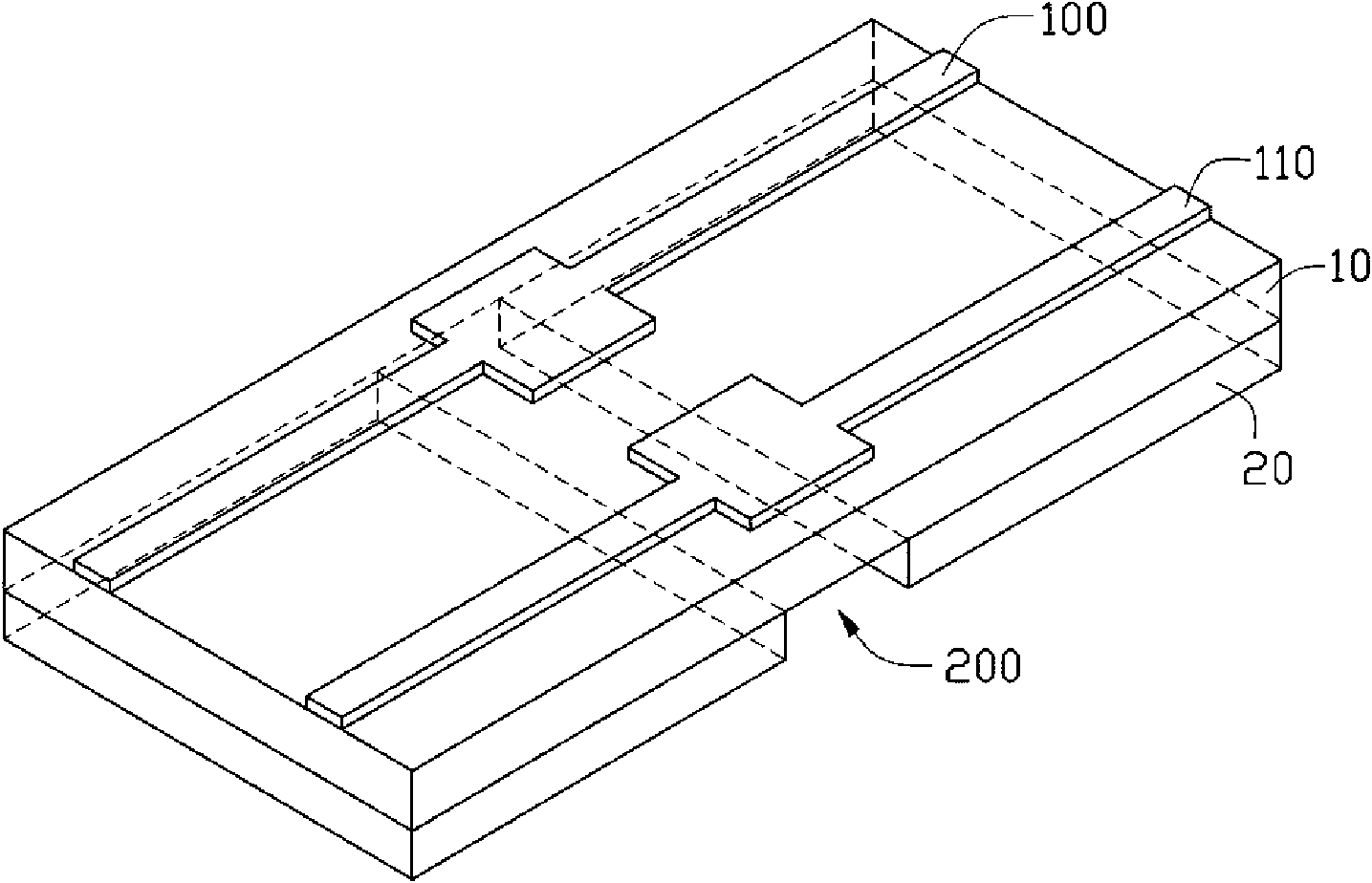

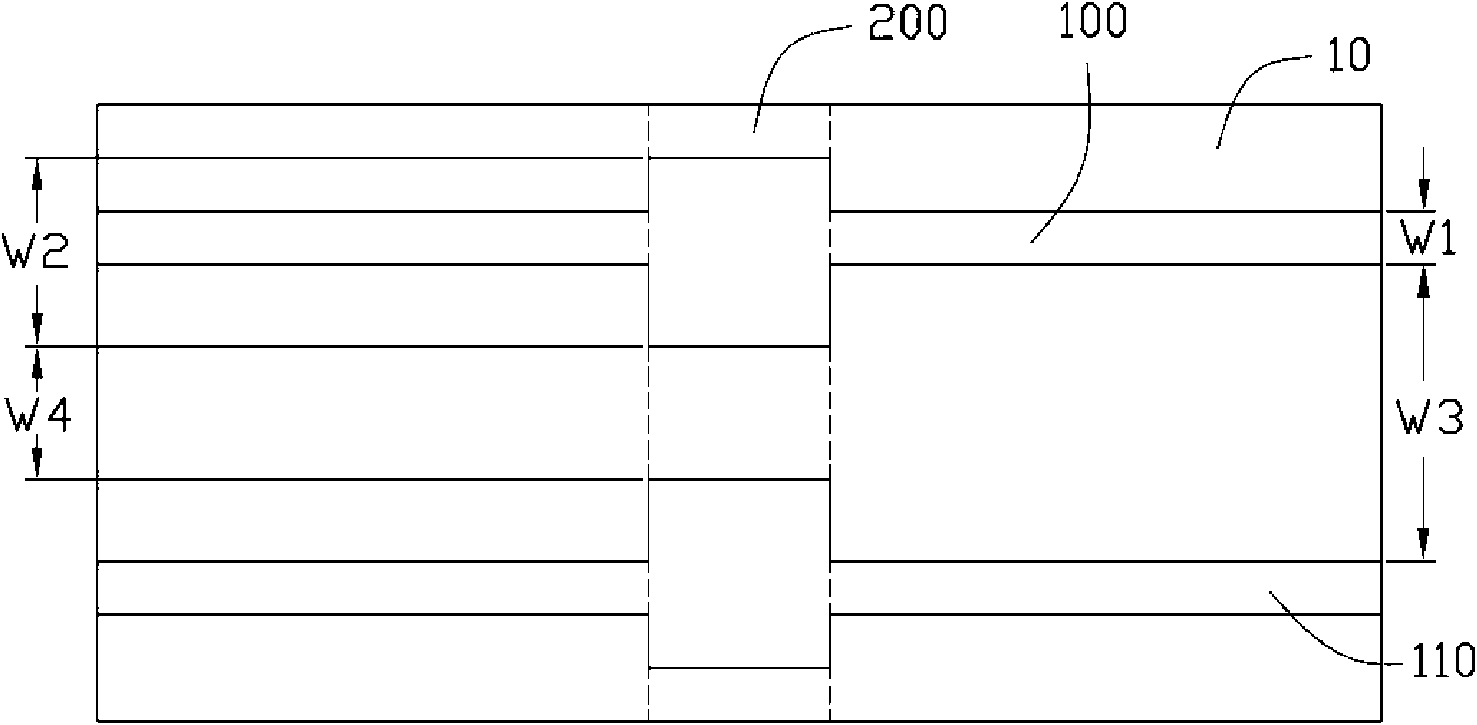

[0010] Please refer to figure 1 and 2 , the preferred embodiment of the printed circuit board of the present invention includes a first layer 10 and a second layer 20 .

[0011] A differential pair including two differential signal lines 100 and 110 is disposed on the first layer 10 . A span groove 200 is disposed on the second layer 20 . When the printed circuit board has fewer layers, different voltage levels need to be cut on the limited power layer, and the cross-slot 200 is formed when the signal line crosses these different voltage cutting planes.

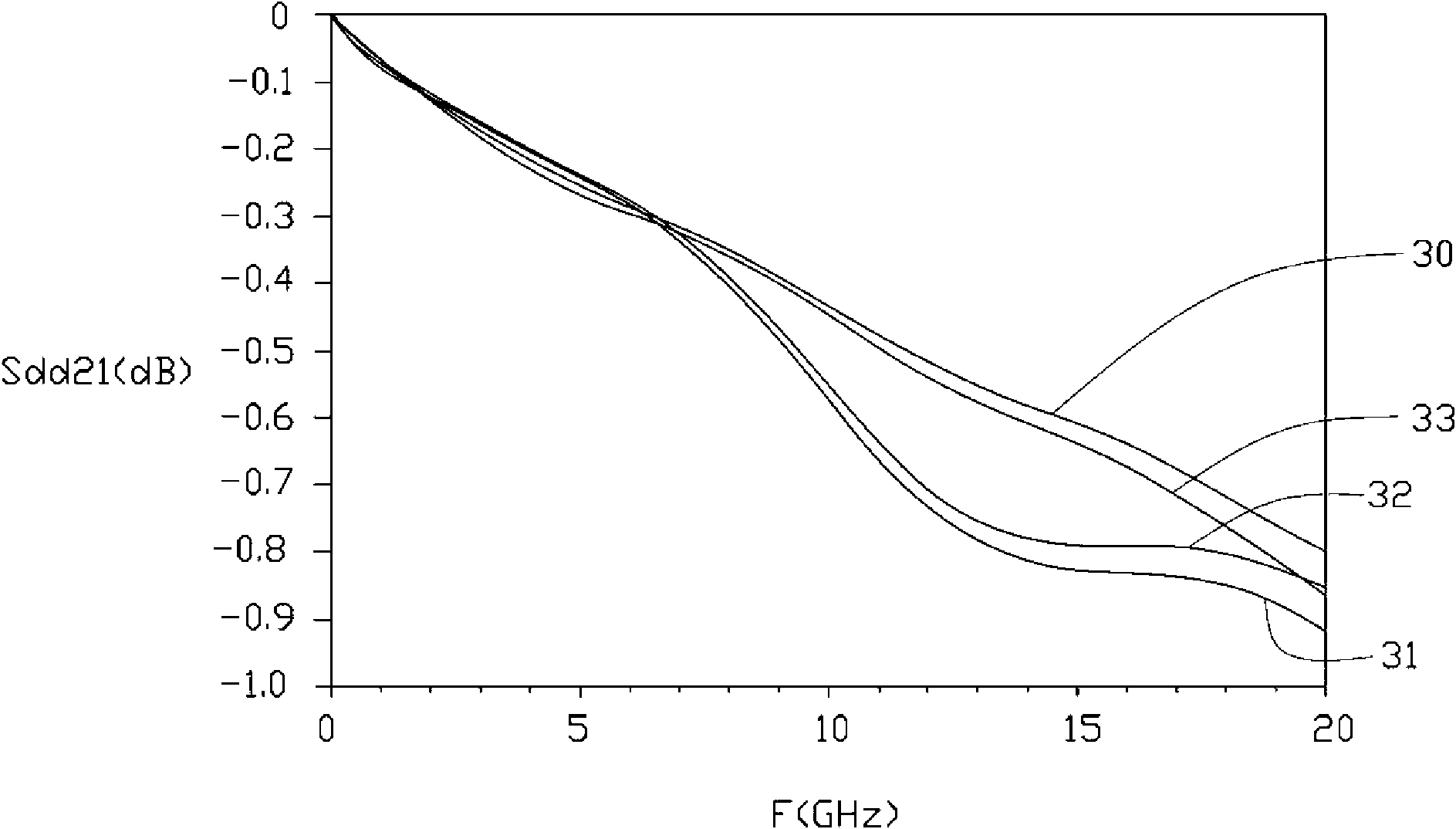

[0012] The line width of the differential signal line 100 above the non-spanning trench 200 is W1, and the line width above the spanning trench 200 is W2, wherein W1 is smaller than W2. The setting of the line width of the differential signal line 110 is the same as that of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com