Extrusion forming equipment and method for laminating flexible material

A flexible material, extrusion molding technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of not being subjected to pressure, warping, and large pressure tools, and achieve the effect of avoiding warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The features and advantages of the present invention will be described in detail with reference to the accompanying drawings.

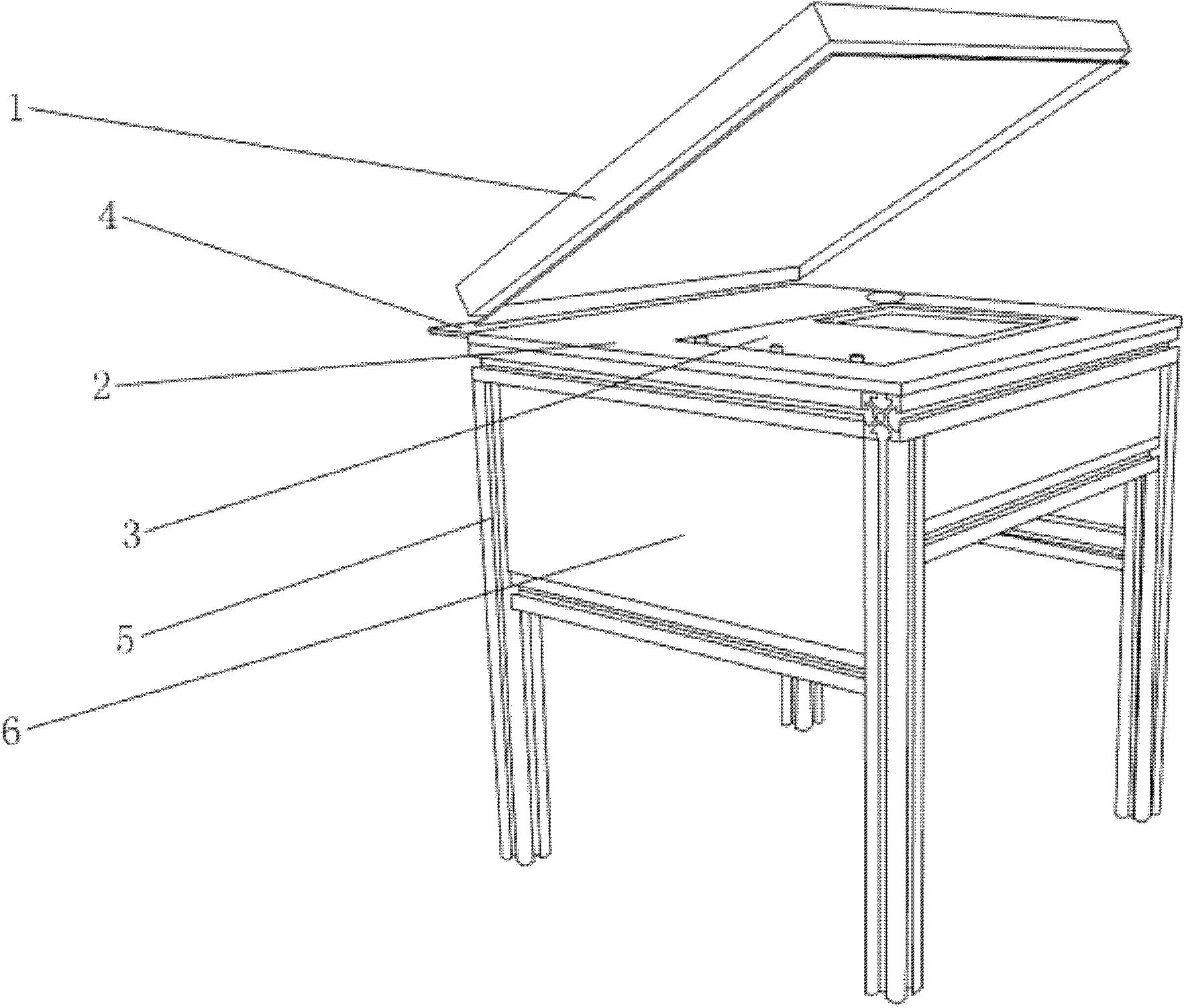

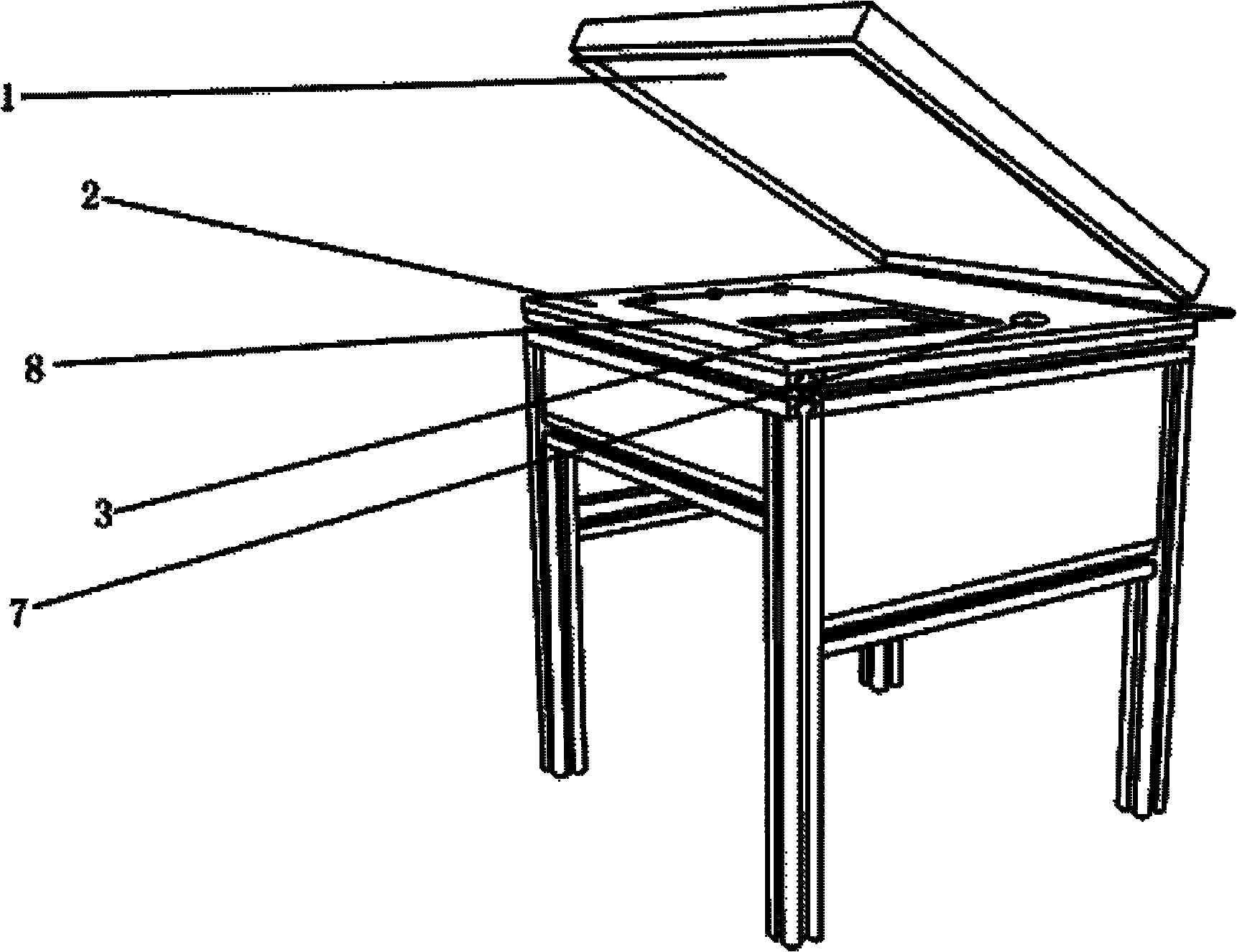

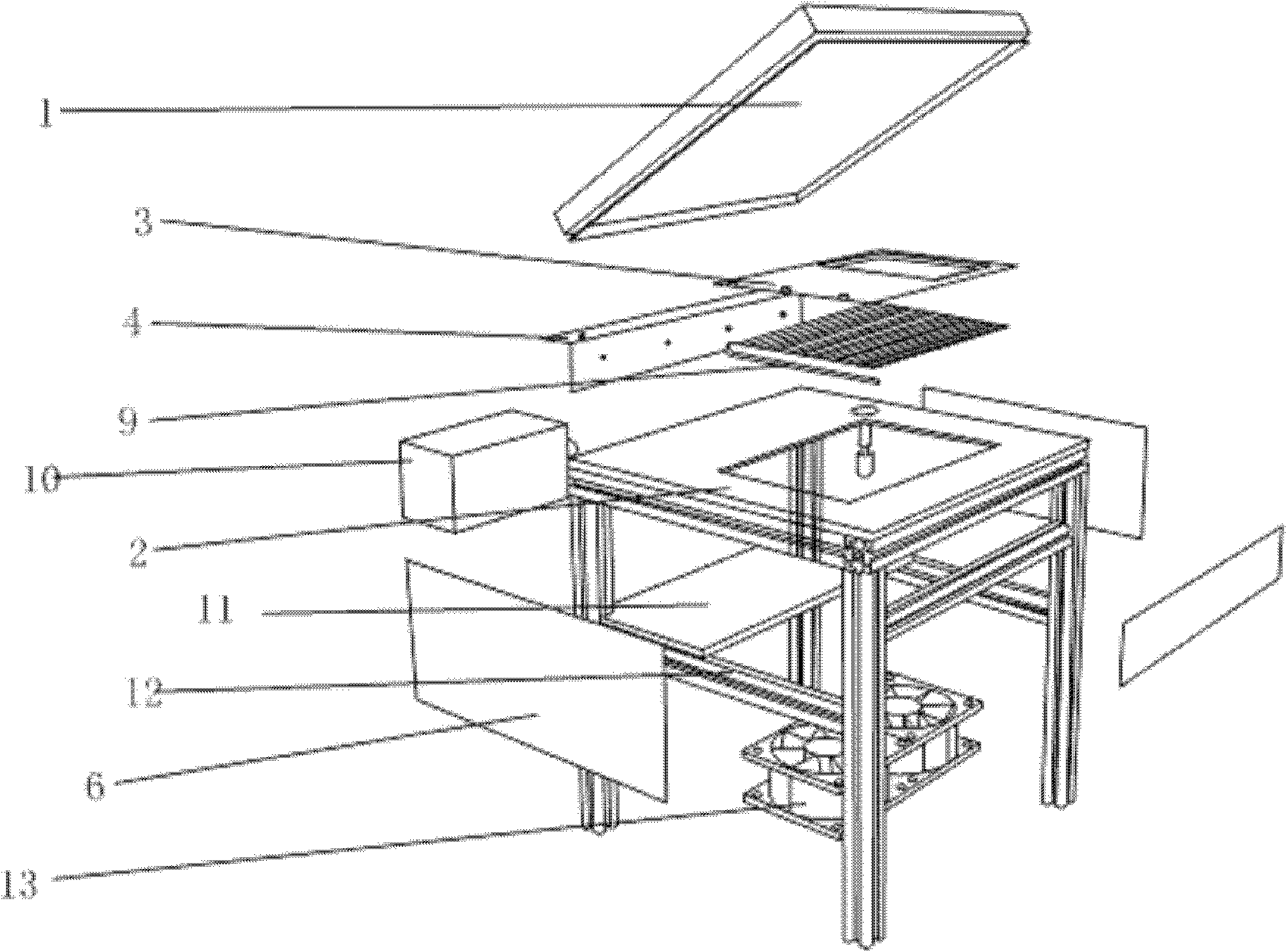

[0047] Please refer to Figure 1 to Figure 8, the extrusion molding equipment of the present invention comprises following main parts: pressure member 1, forming mold (Mandrel) 3, vacuum press (Thin-Air Vacuum Press, TAVP), heating device, cooling device (not shown) and control system (not shown). The forming die 3 is thermally conductive and has recesses for receiving the layer of flexible material and determining the three-dimensional shape of the product to be formed. The pressure member 1 has elasticity and heat resistance, and is configured to cover the forming mold 3 to form an airtight chamber surrounding the material layer. A vacuum press is coupled to the airtight chamber, which deforms the elastic covering surface of the pressure piece 1 tending to conform to the shape of the recess by vacuum suction to compress the material layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com