Protective device for mine drilling construction

A protection device and mine technology, applied in mining devices, safety devices, dust prevention and other directions, can solve the problems of gas, coal dust accidents, affecting drilling efficiency, destroying the operating environment, etc., to improve construction efficiency and improve gas drainage. Efficiency, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

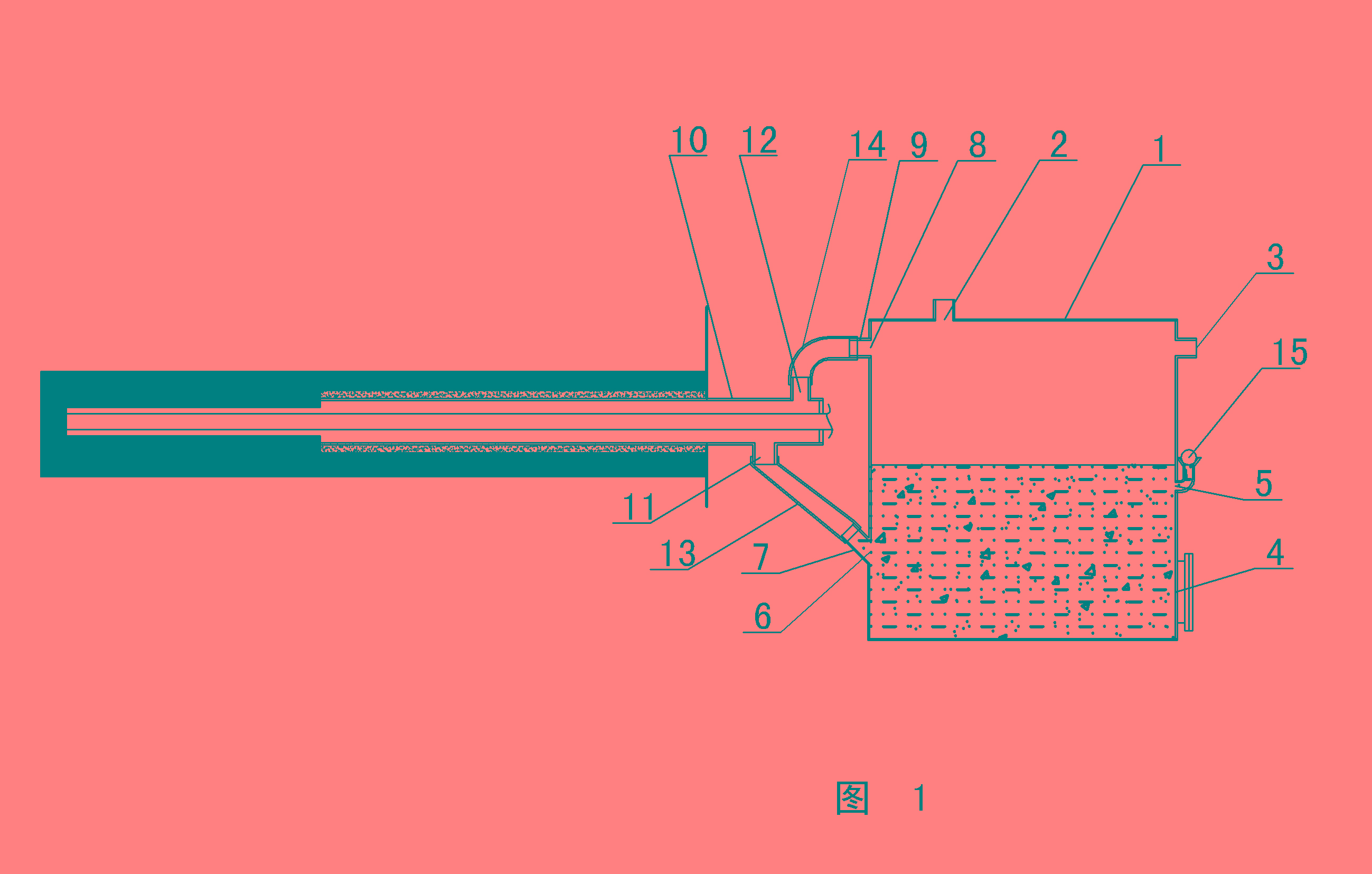

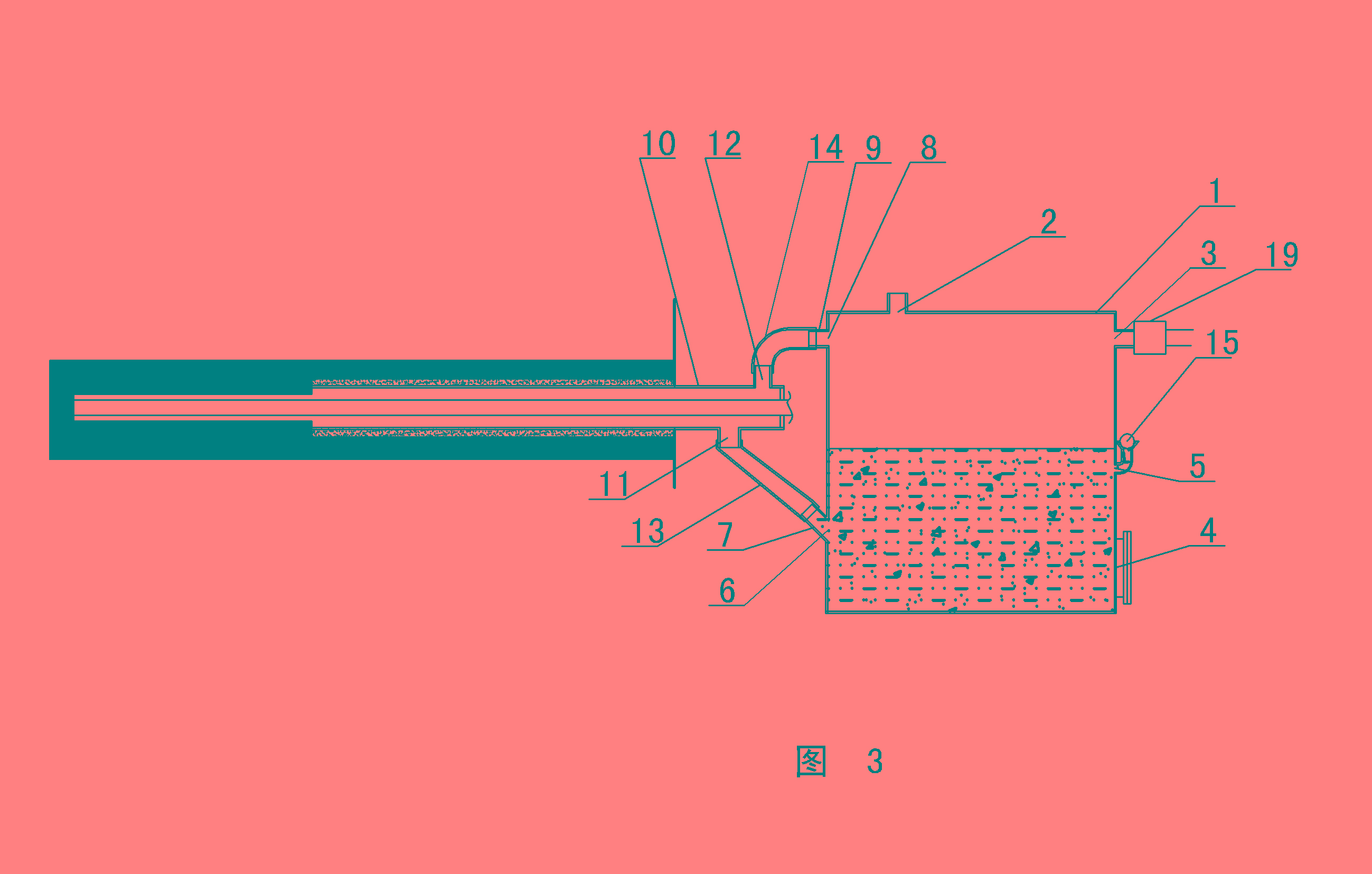

[0021] Such as figure 1 As shown, embodiment 1 of the protection device of the present invention includes a dust removal box 1 for holding water inside, and the top of the dust removal box 1 is provided with a water injection port 2 and an air outlet 3 communicating with the inside of the box, and the air outlet 3 is connected to the The gas extraction pipe connected to the extraction device, the bottom of the dust removal box 1 is provided with a slag outlet 4 communicating with the inside of the box, and the slag outlet 4 is equipped with a flange and a flange for slag discharge control. The middle part of the dust removal box 1 is provided with an overflow port 5 communicating with the inside of the box for maintaining the liquid level in the box. The overflow port 5 is equipped with an automatic water discharge device 15. The automatic water discharge device 15 is a one-way valve, and its function is to control the water level in the box. In order to maintain a certain spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com