Device for detecting leak tightness of inner water tank of vacuum-tube solar water heater

A technology of solar water heater and airtightness detection, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness, and detecting the appearance of fluid at the leakage point, etc. It can solve the problem of damage to stainless steel plates, affecting the normal use of users, and water leakage at joints, etc. problems, to achieve the effect of easy selection, avoid missed inspection, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

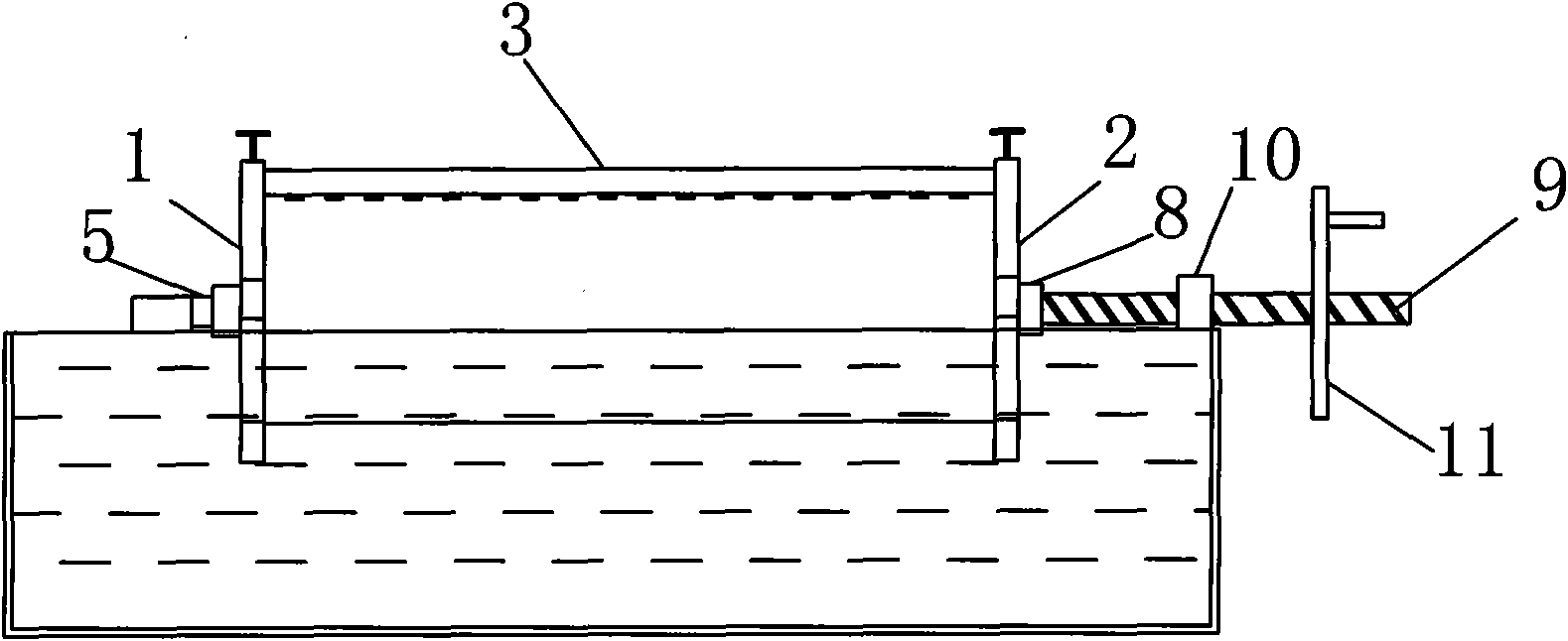

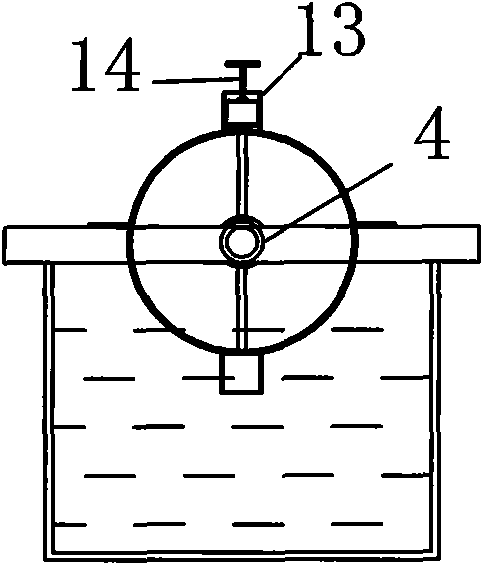

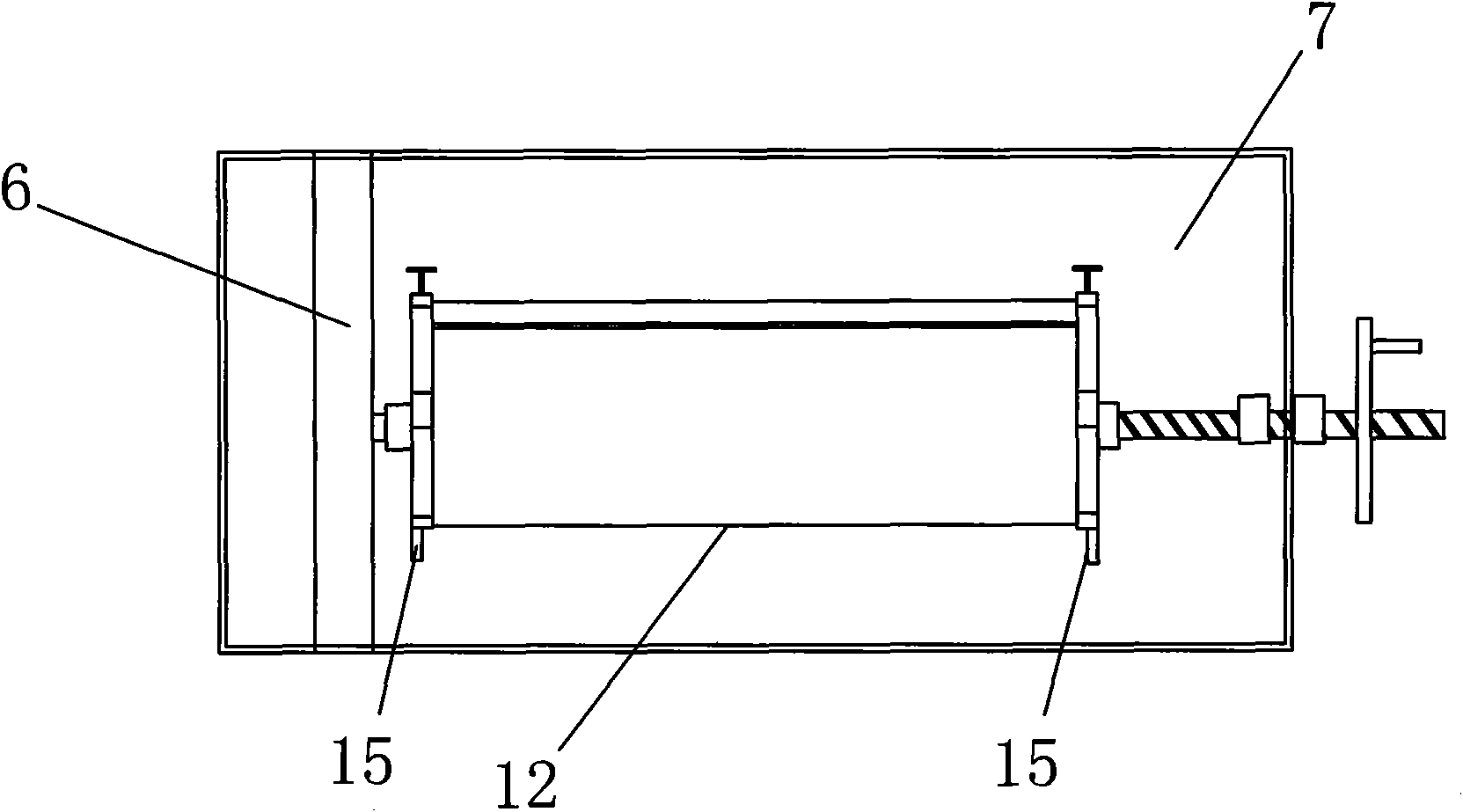

[0036] like figure 1 , 2 , 3 and 4, the detection device includes three parts: a fixed chuck 1, a movable chuck 2, and a pressing device 3, wherein the fixed chuck 1 and the movable chuck 2 are ring-shaped members fixed with reinforcing ribs, The axes of the two are installed relative to each other; the axis of the fixed chuck 1 is provided with a sliding bearing 4, and the rotating shaft 5 passes through the sliding bearing of the axis of the fixed chuck 1 and is fixed on the bracket 6, and the bracket 6 is installed on the two sides of the detection groove 7. On the two side plates, the shaft center of the movable chuck 2 is provided with an internal hollow fixed shaft sleeve 8, and a section of the threaded rod 9 is flexibly connected with the shaft sleeve 8, and the other end passes through and is fixed on the detection groove 7 end plates, and is provided with internal threads. After the sleeve 10, it is connected with the rotatable adjustment wheel 11, and the threaded ...

Embodiment 2

[0041] like figure 1 , 2 , 3 and 5, the basic structure of the detection device is the same as that of embodiment 1, the difference is that the corresponding positions of the pressing device 3 are installed on the circumference of the fixed chuck 1 and the movable chuck 2, and other equally divided positions are provided with matching weights. Weight 15.

[0042] When using this equipment to detect the tightness of the inner liner of the vacuum water tank 12 to be tested, first fill the detection tank 7 with clean water, then seal the water inlet pipe interface and the water outlet pipe interface of the water tank 12 to be tested, and seal the installation port of the vacuum tube heat collector tube with rubber. Soft plug 21 is sealed, prevents air leakage;

[0043] Then the end of the water tank 12 to be tested is provided with the exhaust pipe 19 and is stuck in the movable chuck 2, and the other end is stuck in the fixed chuck 1, and the heat collector installation port o...

Embodiment 3

[0046] like figure 1 , 2 , 3 and 6, the basic structure of the detection device is the same as that of embodiment 1, the difference is that the rubber plug 21 that seals the installation port of the vacuum heat collecting tube is uniformly fixed on the compression device 3, and can tighten the device 14 and compression The end of the device is set as a card slot type that cooperates with each other, and the installation port of the vacuum heat collecting tube is sealed and pressed tightly, so as to realize the tightness of the inner tank under a relatively high pressure condition.

[0047] The end of the water tank 12 to be tested provided with the exhaust pipe 19 is clamped in the movable chuck 2, and the other end is clamped into the fixed chuck 1, and gas is introduced from the exhaust pipe 19 of the water tank 12 to be tested at a pressure of 0.06 Mpa, then close the air valve of the exhaust pipe 19, rotate the fixed chuck 1 and the movable chuck 2, observe whether bubble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com