Gas preprocessing method and device applied to analytical instruments

A gas pretreatment and analytical instrument technology, applied in the preparation of test samples, etc., can solve the problems of detection impact, frequent interruption, and heavy system maintenance workload, so as to reduce replacement costs, long service life, and reduce maintenance workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

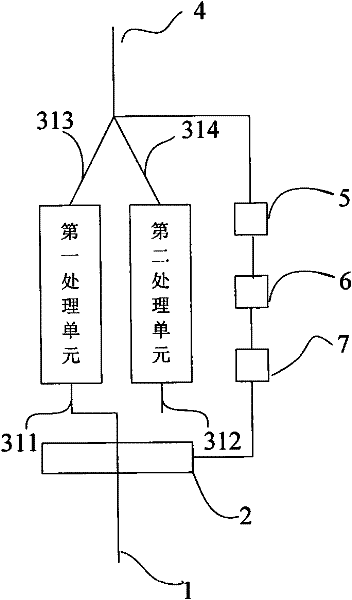

[0062] See figure 2 , A gas pretreatment device used in an analytical instrument for removing moisture in gas, the processing device includes an input port 1, a selection module 2, a processing module, an output port 4, a monitoring module 5, a judgment module 6 and Control module 7.

[0063] The processing module includes a first processing module and a second processing module. The first processing module includes an input end 311, a first processing unit, an output end 313, a first air inlet, and a first air outlet. The input end 311, the first processing unit and the output end 313 form a first processing channel, and the first air inlet, the first processing unit and the first exhaust port form a first regeneration channel. The first air inlet is shared with the output terminal 313, and the first air outlet is shared with the input terminal 311. The second processing module includes an input end 312, a second processing unit, an output end 314, a second air inlet, and a s...

Embodiment 2

[0080] See Figure 4 , A gas pretreatment device used in analytical instruments, the difference from embodiment 1 is:

[0081] 1. The input end 311 of the first processing channel is shared with the first air inlet, and the output end 313 is shared with the first air outlet; the input end 312 of the second processing channel is shared with the second air inlet, and the output end 314 is shared with the second air inlet. Two exhaust ports are shared;

[0082] 2. It also includes a switch module 32 for controlling the output end 313 (first exhaust port) and the input end 312 (second intake port), as well as the output end 314 (second exhaust port) and the input end 311 (first exhaust port). The air inlet) is on or off.

[0083] This embodiment also provides a gas pretreatment method applied to an analytical instrument. The difference from Embodiment 1 is:

[0084] In step c, the processed gas is discharged from the output port 313 or the output port 314, a part is output through the ou...

Embodiment 3

[0086] See Figure 5 , A gas pretreatment device used in analytical instruments to remove solid particles such as dust in the gas. The difference from Embodiment 1 is:

[0087] 1. It also includes a third processing channel, including an input end, a third processing unit, an output end, a third air inlet, and a third air outlet; wherein, the output end is shared with the third air inlet, and the input The end is shared with the third exhaust port; the third intake port communicates with the output ends on the first and second processing channels;

[0088] 2. Each processing unit uses filters to remove solid particles such as dust in the gas;

[0089] 3. The monitoring module uses a pressure sensor to determine whether the processing unit needs regeneration by measuring the pressure of the gas downstream of the processing channel.

[0090] This embodiment also provides a gas pretreatment method applied to an analytical instrument to remove solid particles such as dust in the gas. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com