MEMS (Micro Electronic Mechanical System) clamped beam type online microwave power sensor and production method thereof

A microwave power and beam-supported technology, which is applied in the field of MEMS solid-supported beam-type online microwave power sensor and its preparation, can solve the problems of consuming input signal power and achieve the effect of low loss and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

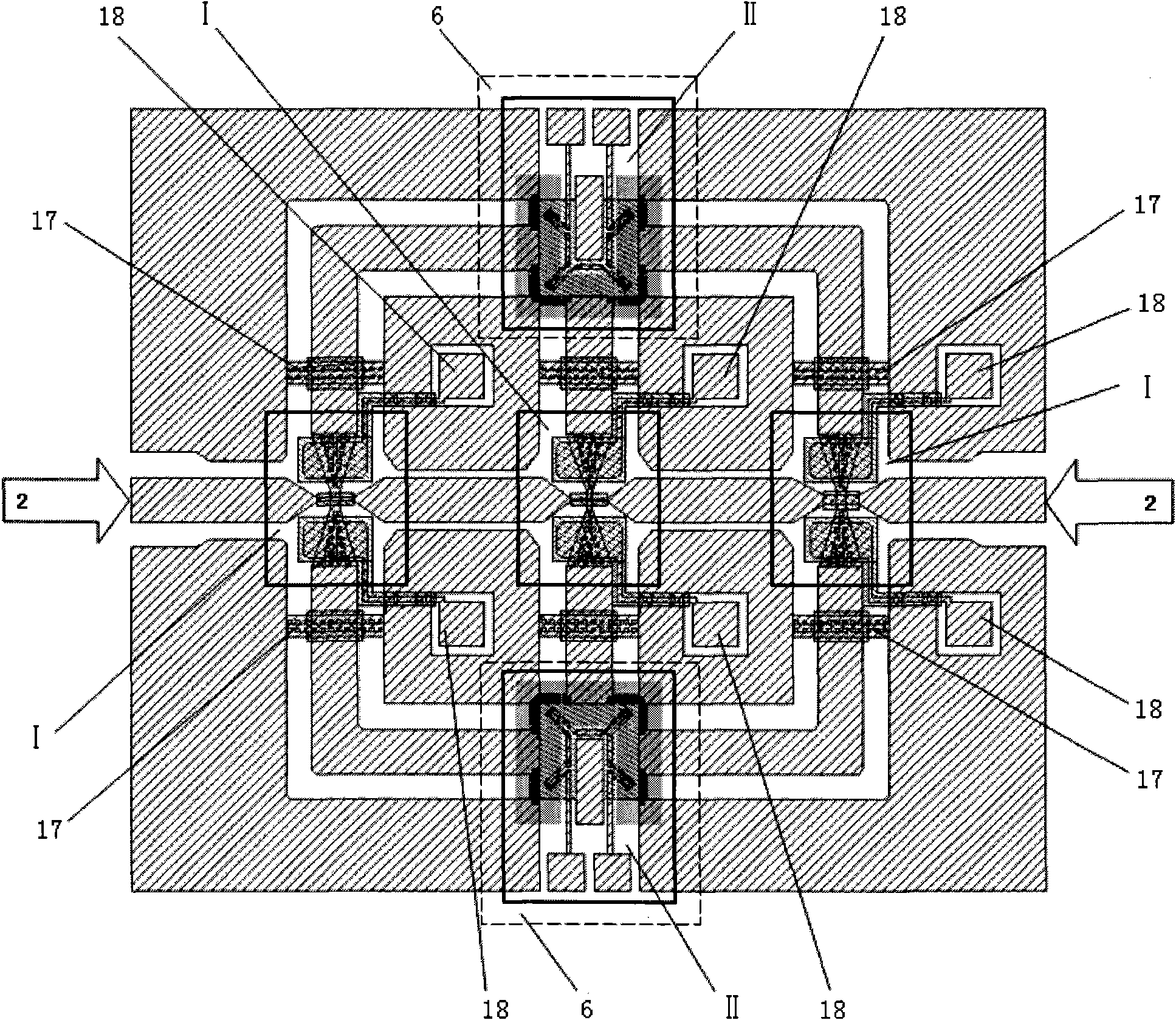

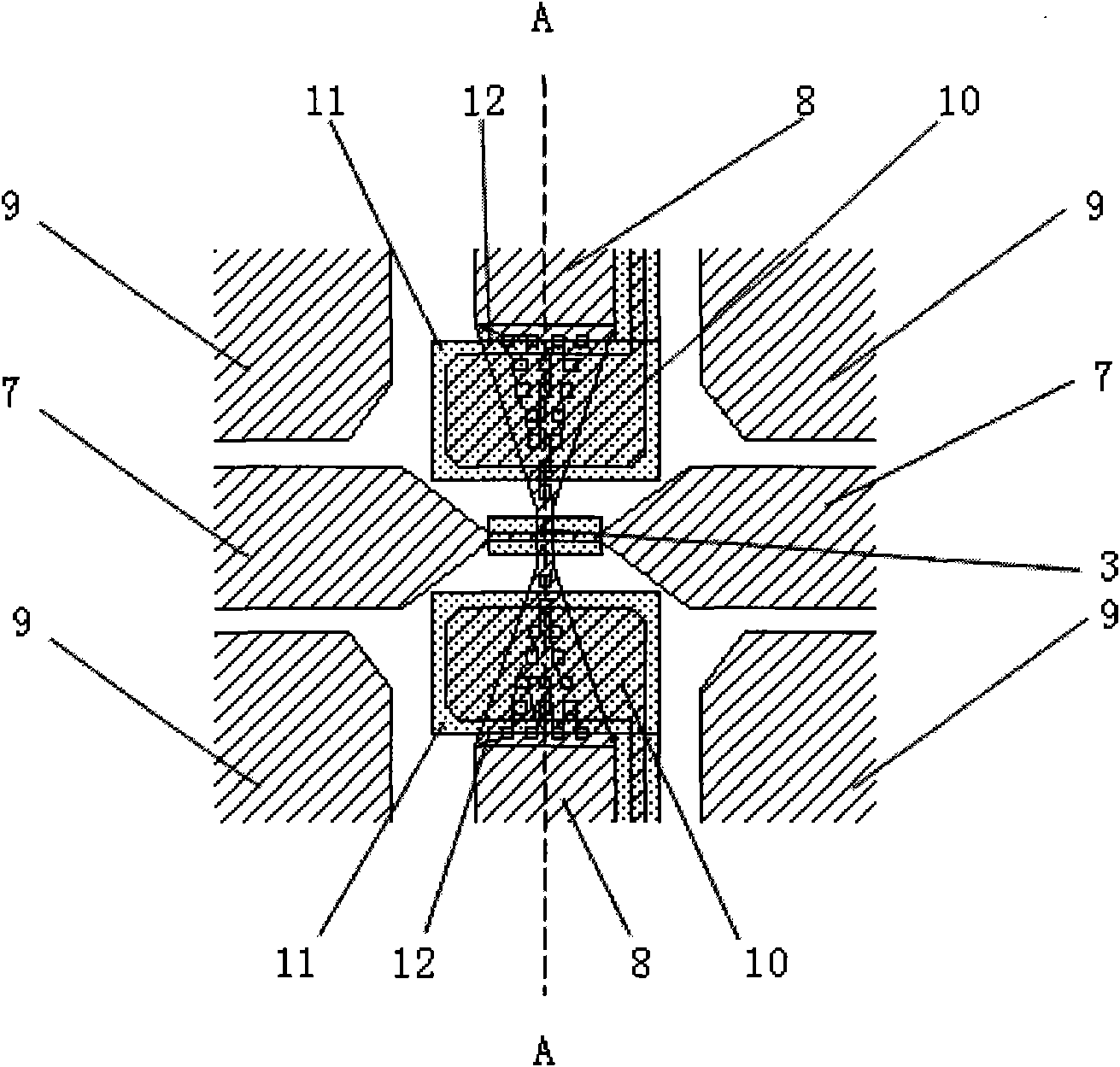

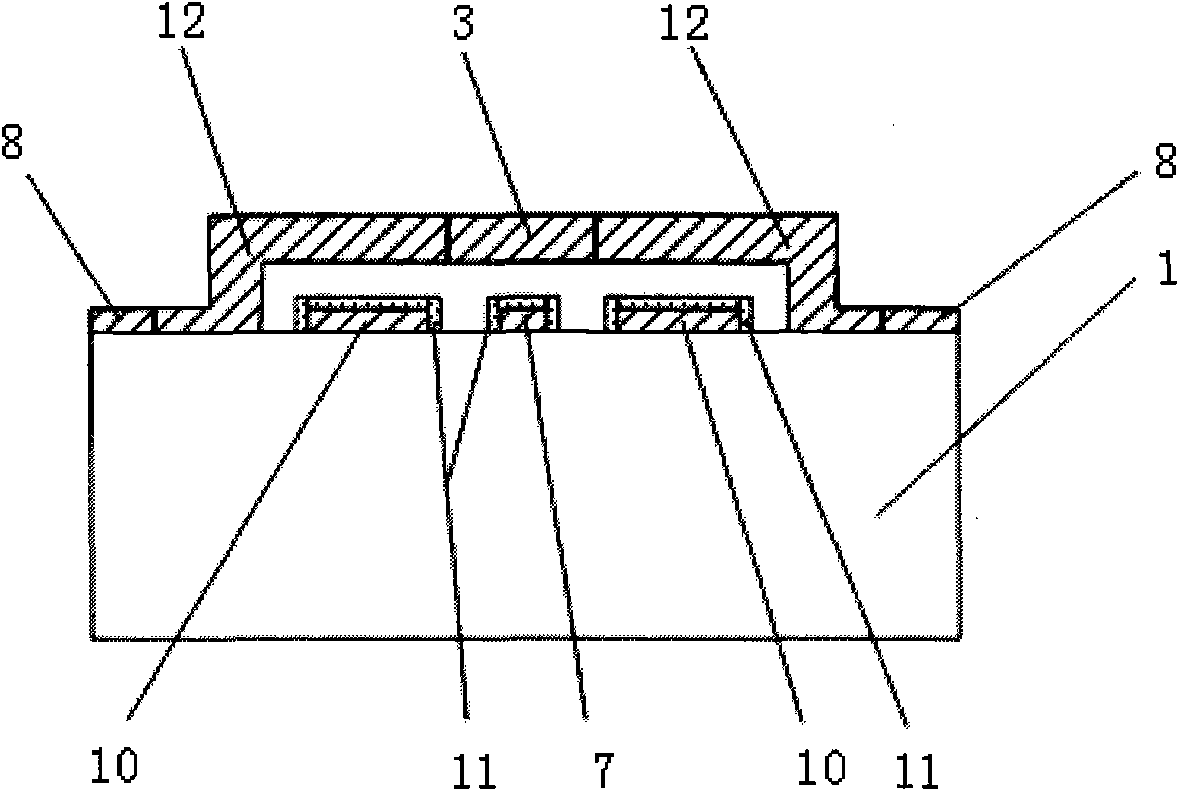

[0049] Such as figure 1 , 2 , 3 and 4 show a MEMS fixed-supported beam type online microwave power sensor, which is provided with CPW, three MEMS fixed-supported beam structures and a terminal composed of a terminal resistor 13 and a thermopile on a gallium arsenide substrate 1 Microwave power monitoring system 6 ( figure 1 part in the dotted frame).

[0050]The CPW includes a main line CPW signal line 7, a secondary line CPW signal line 8 and a CPW ground line 9, the main line CPW signal line 7 and CPW ground line 9 constitute the main line CPW, and the secondary line CPW signal line 8 and CPW ground line 9 constitute The secondary line CPW is connected to the ground line 9 that is cut off through the air bridge 17 .

[0051] The MEMS fixed beam structure includes a fixed beam 3 and an anchor area 12, the fixed beam 3 spans above the main line CPW signal line 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com