Power capacitor

A technology of power capacitors and capacitors, which is applied to the terminals of fixed capacitors and components of fixed capacitors, etc., can solve the problems of multiple processing procedures, large ceramic specificity, fragile anti-pollution flashover performance, etc., and achieve simplified structure and processing procedures , save parts and assembly process, excellent effect of anti-fouling flashover performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

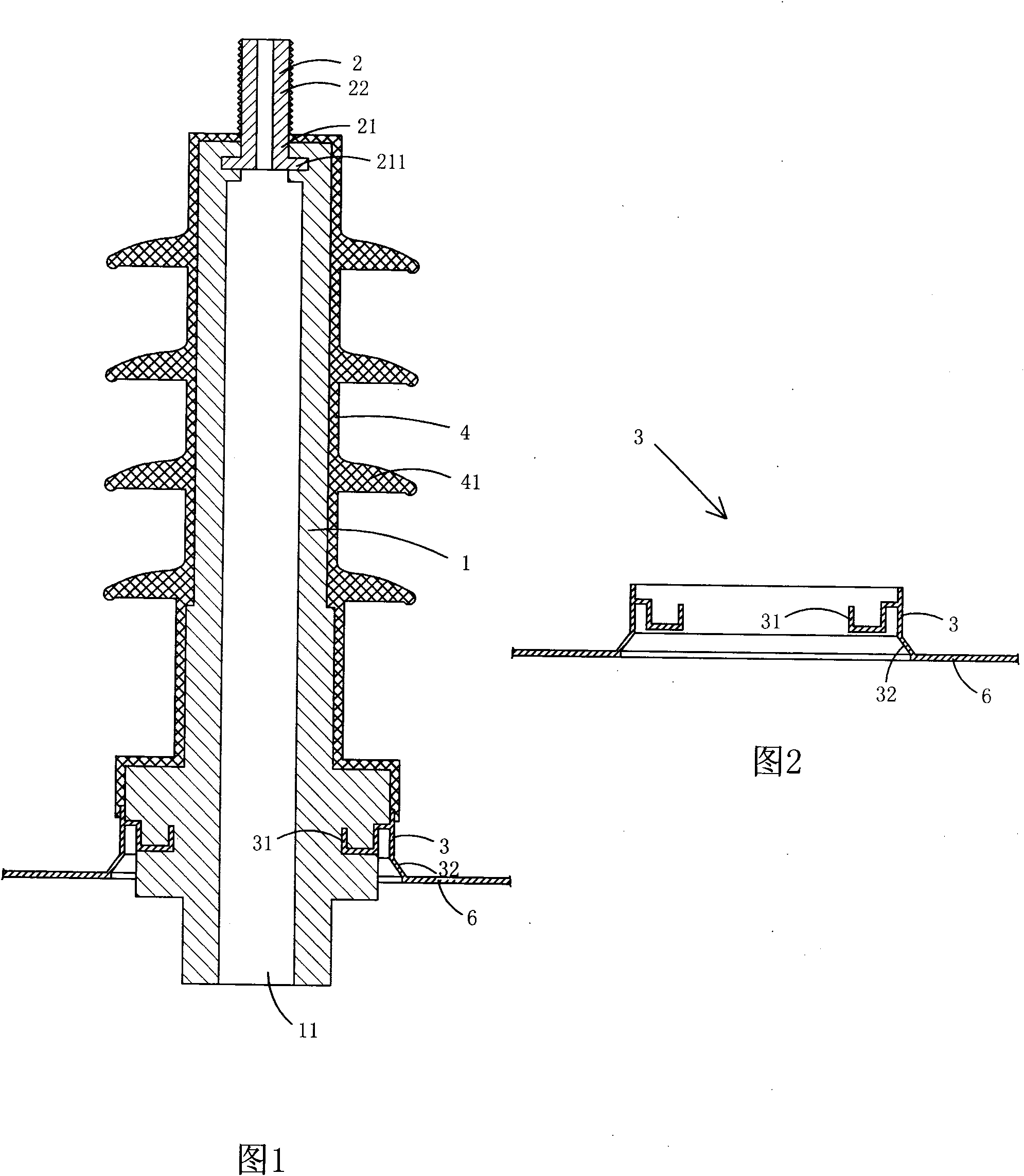

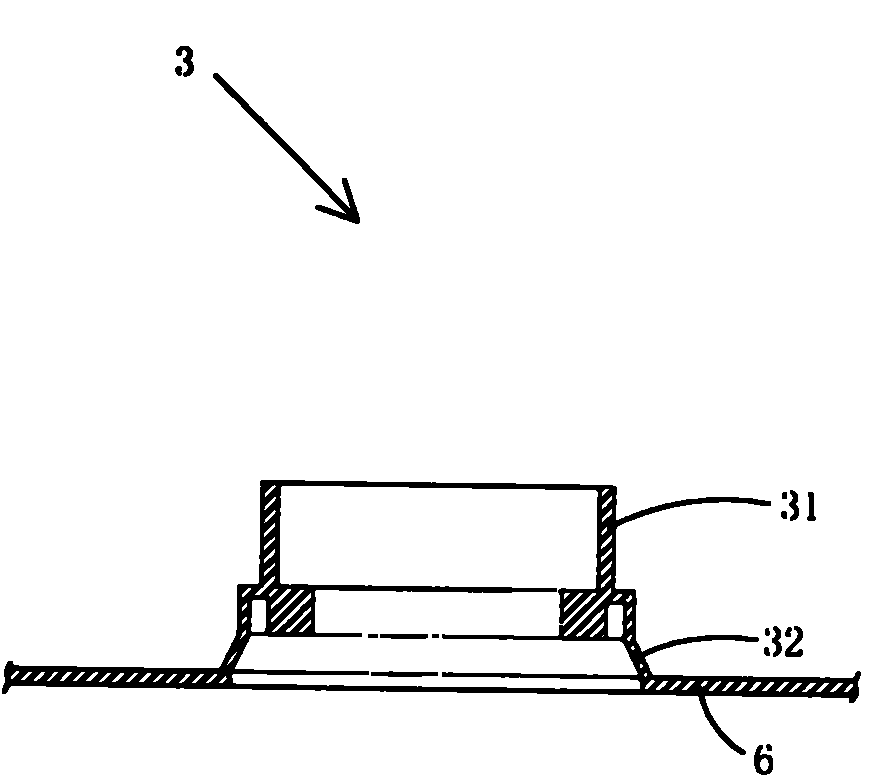

[0024] Figure 1 to Figure 2 A first embodiment of the invention is shown, in which figure 1 It is a half-sectional view of the first structure of the present invention; figure 2 yes figure 1 Half-section view of the metal mount in the power capacitor shown;

[0025] This embodiment is a terminal for power capacitors, see Figure 1 to Figure 2 , including a capacitor case 6 and a terminal 1 fixed on the capacitor case 6, the terminal 1 includes an insulator body 1, a metal terminal bolt 2 arranged on the top of the insulator body 1 and a metal terminal bolt 2 arranged on the insulator body 1 The metal mounting seat 3 at the bottom; the metal mounting seat 3 is a protruding piece directly formed on the capacitor case 6 by stamping; the insulator body 1 is made of composite insulating resin; the metal mounting seat 3 is provided with There is a plastic sealing part 31 for fixed connection with the insulator body 1, and a mounting part 32 for connecting with the capacitor ca...

Embodiment 2

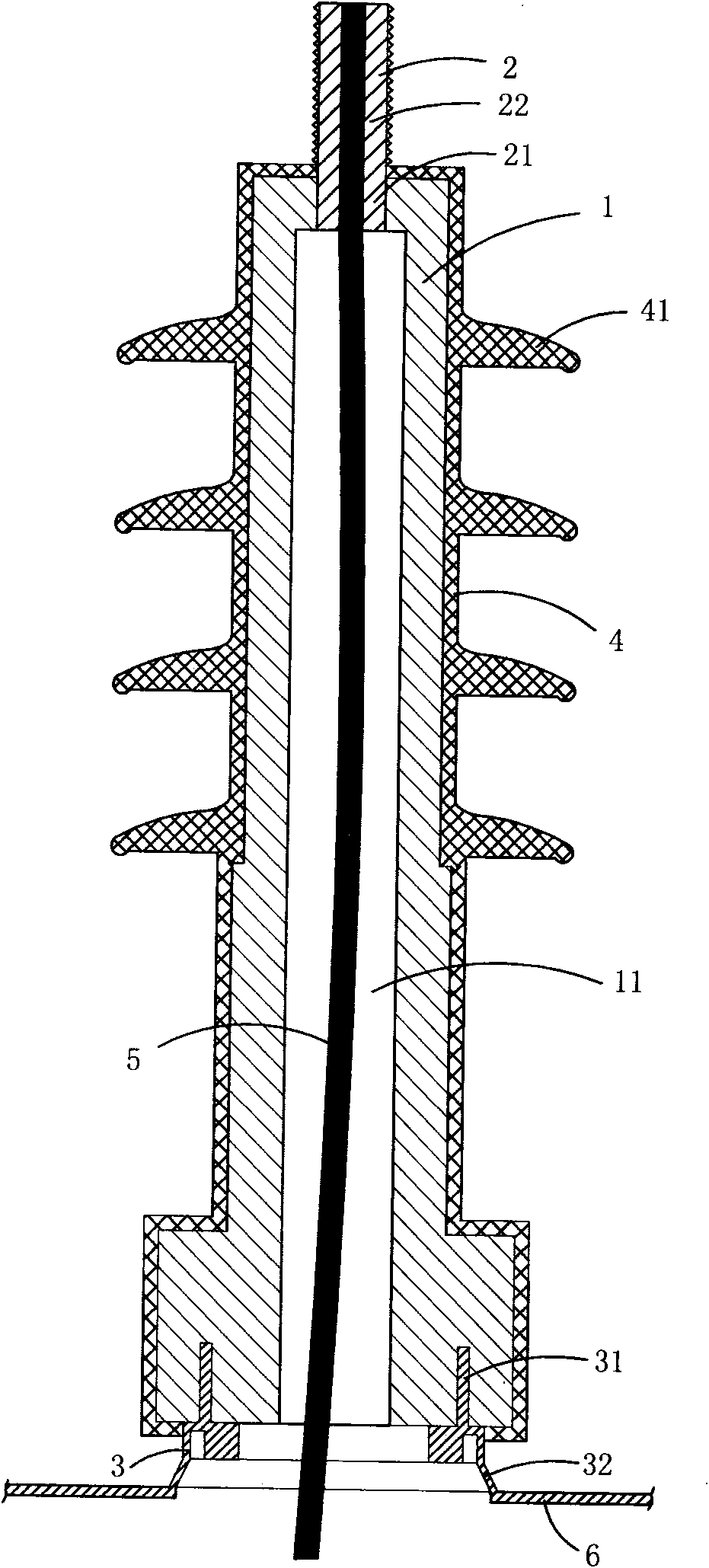

[0034] Figure 3 to Figure 4 A second embodiment of the invention is shown, in which image 3 It is a half-sectional view of the second structure of the present invention; Figure 4 yes image 3 Half cutaway view of the metal mount in the power capacitor shown.

[0035] This embodiment is basically the same as Embodiment 1, except that the top end of the plastic sealing part 31 protrudes upwards from the cavity surrounded by the mounting part 32 , and the mounting part 32 is located on the bottom wall of the insulator body 1 below.

[0036] The insulator body 1 is provided with an annealed copper wire 5 in its through hole 11 , the upper end of the annealed copper wire 5 is electrically connected to the metal connection bolt 2 , and the metal mounting base 3 is insulated from the annealed copper wire 5 .

[0037] The insulator body 1 is made of glass fiber reinforced epoxy resin; the metal mounting base 3 is made of stainless steel.

[0038] In addition, in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com