Xenon lamp and manufacturing process thereof

A technology of xenon lamp and process steps, applied in the field of lighting, can solve the problems such as the failure of the lamp tube to work normally, affect the service life of the lamp tube, damage to the HID xenon lamp, etc., and achieve the effects of stable inflation process, short installation time and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

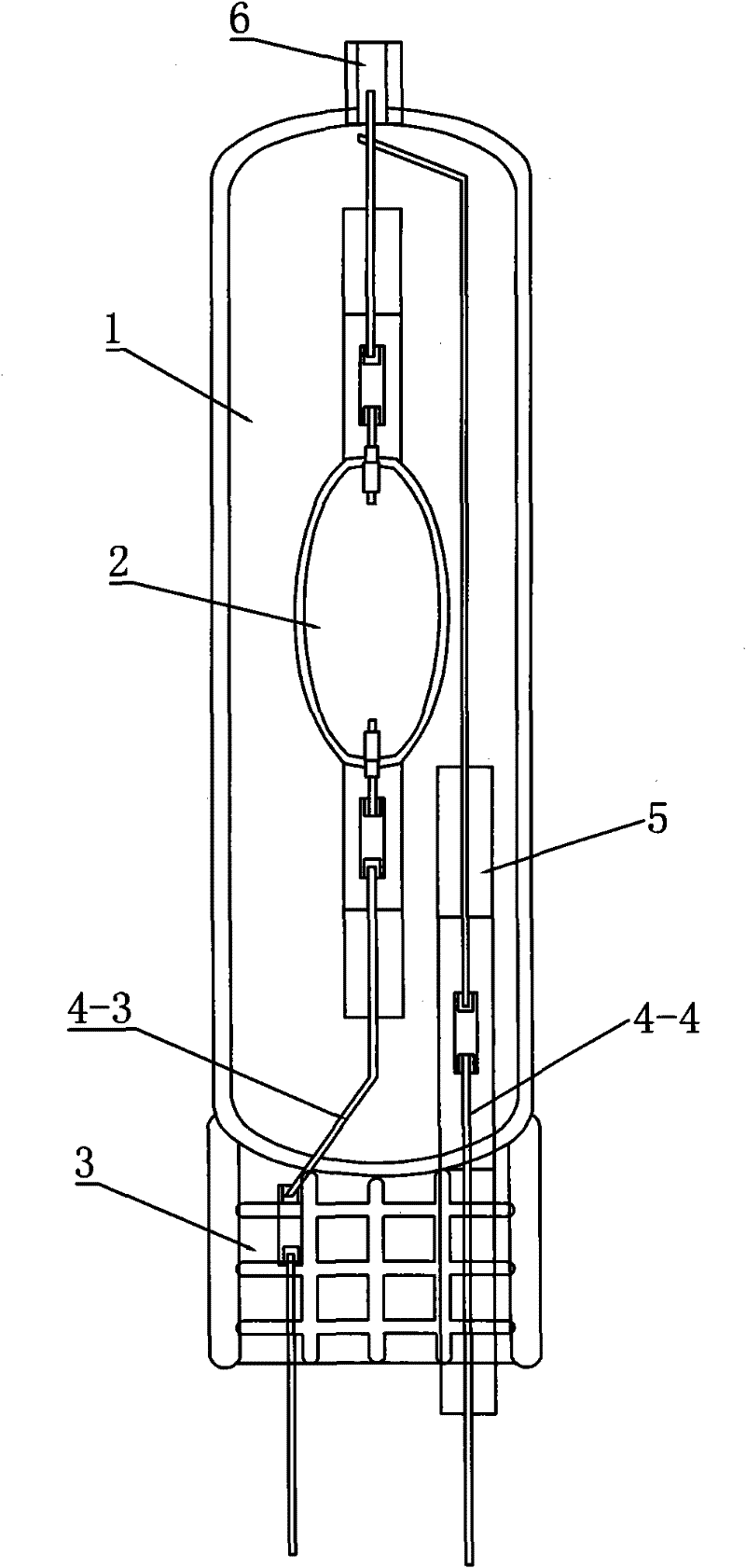

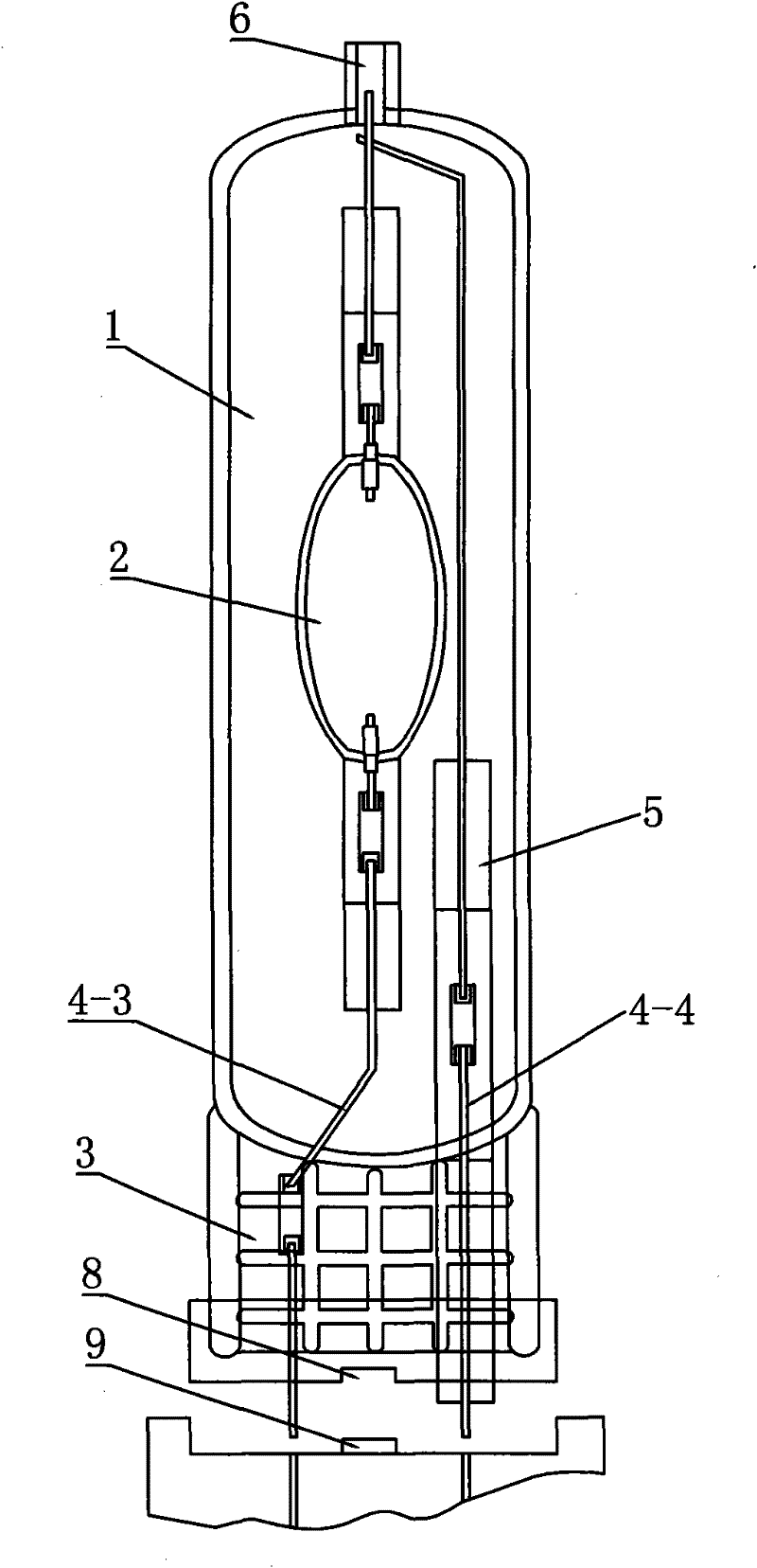

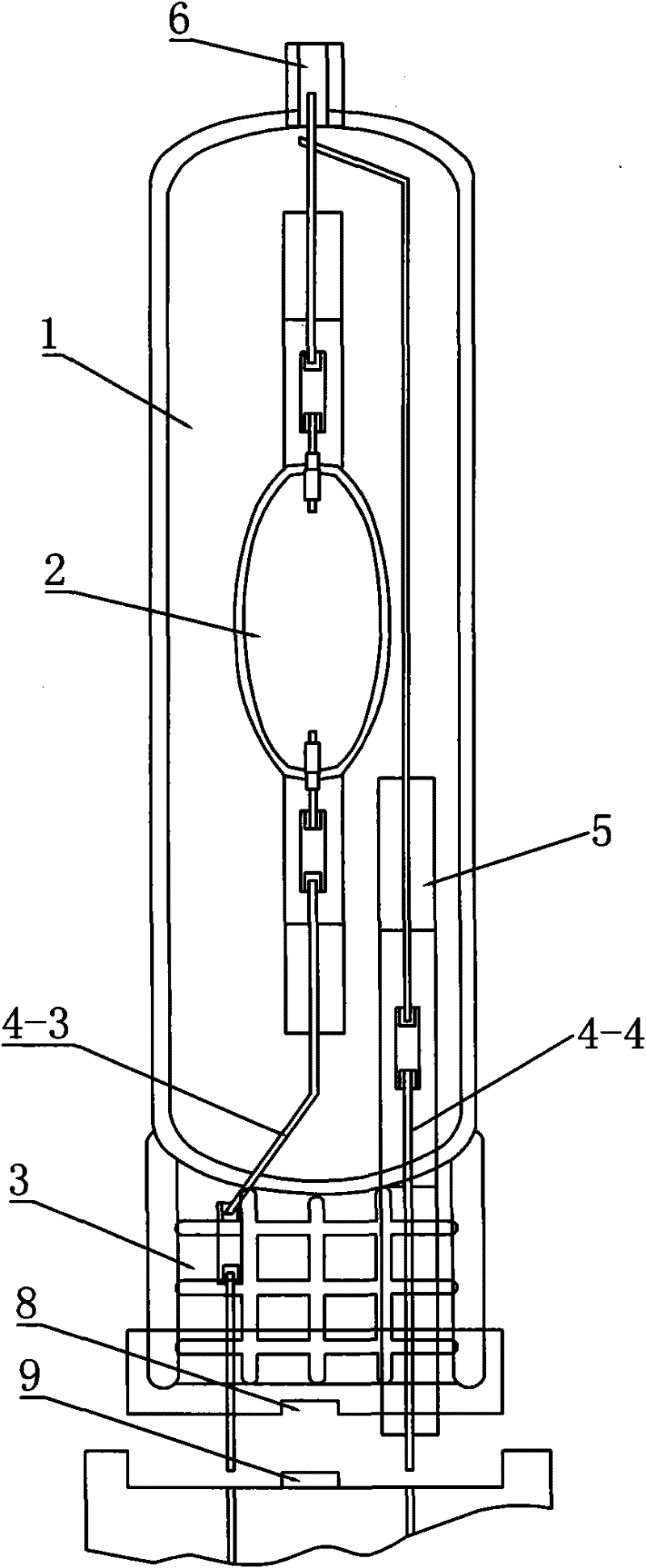

[0024] like figure 1 , figure 2 As shown, a xenon lamp of the present invention includes a lamp tube outer casing 1 and a luminous tube 2 and a lamp cap 7 arranged therein. , 4-2 pass through the pressure seal 3, the two electrode lead wires are respectively connected with molybdenum sheets 4-3, 4-4, the molybdenum sheets of the two electrode lead wires are misplaced, and are respectively fixed in the pressure seal 3 and the inner cavity of the lamp tube jacket 1, The molybdenum sheet 4-4 located in the inner cavity of the lamp tube casing 1 is sleeved with an insulating sleeve 5, and the insulating sleeve 5 extends downward and passes through the pressure seal 3 together with the electrode lead wire connected to the inner molybdenum sheet 4-4. In this implementation, the insulating sleeve 5 is a quartz glass tube or a ceramic tube sleeve. The top of the lamp tube jacket 1 is provided with a ventilation hole 6 , and an electrode lead outside the luminous tube has a pole ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com