Pellet resistor with multi-cascade attenuator circuit

A technology of attenuating circuits and chip resistors, applied in circuits, electrical components, waveguide-type devices, etc., can solve the problems of narrow operating frequency band, increase of third-order intermodulation impurities, large reflection loss, etc., to avoid local thermal shock, The effect of good index consistency and high working frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

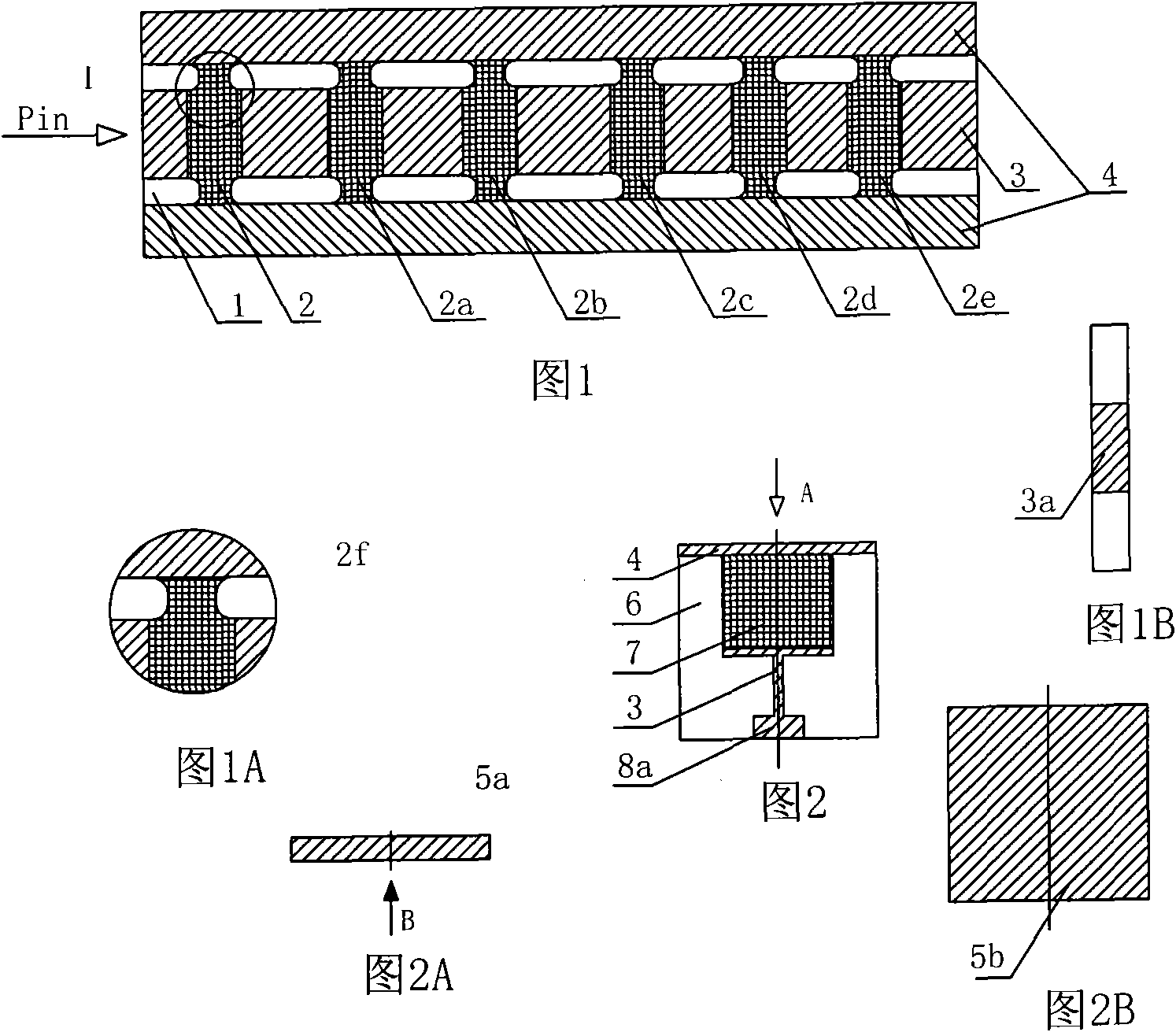

[0016] Embodiment: In this embodiment, chip resistors with multi-cascade attenuation circuits are provided with attenuation resistors 2, 2a, 2b, 2c, and 2d whose attenuation degree increases successively on the rectangular substrate 1 along its length direction from the input end to the terminal interval. , 2e, wherein the attenuation resistor 2e closest to the substrate terminal is a matching terminal capable of completely absorbing the remaining signal power. The attenuation resistors are connected with the central conduction band 3 provided on the substrate, the two sides of the substrate 1 are provided with grounding microstrips 4, and the two ends of the substrate are provided with end faces communicated with the central conduction band Electrode 3a.

[0017] combine Figure 1A , the grounding microstrip 4, the central conduction strip 3 and each attenuation resistor are transitionally connected with an arc-shaped intermodulation angle 2f. The principle characteristics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com