Filling type low-temperature logistic system

A logistics system and filling technology, applied in the field of filling stations, can solve problems such as affecting the surface quality of commodities, low cooling capacity, and easy corrosion of cooling pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

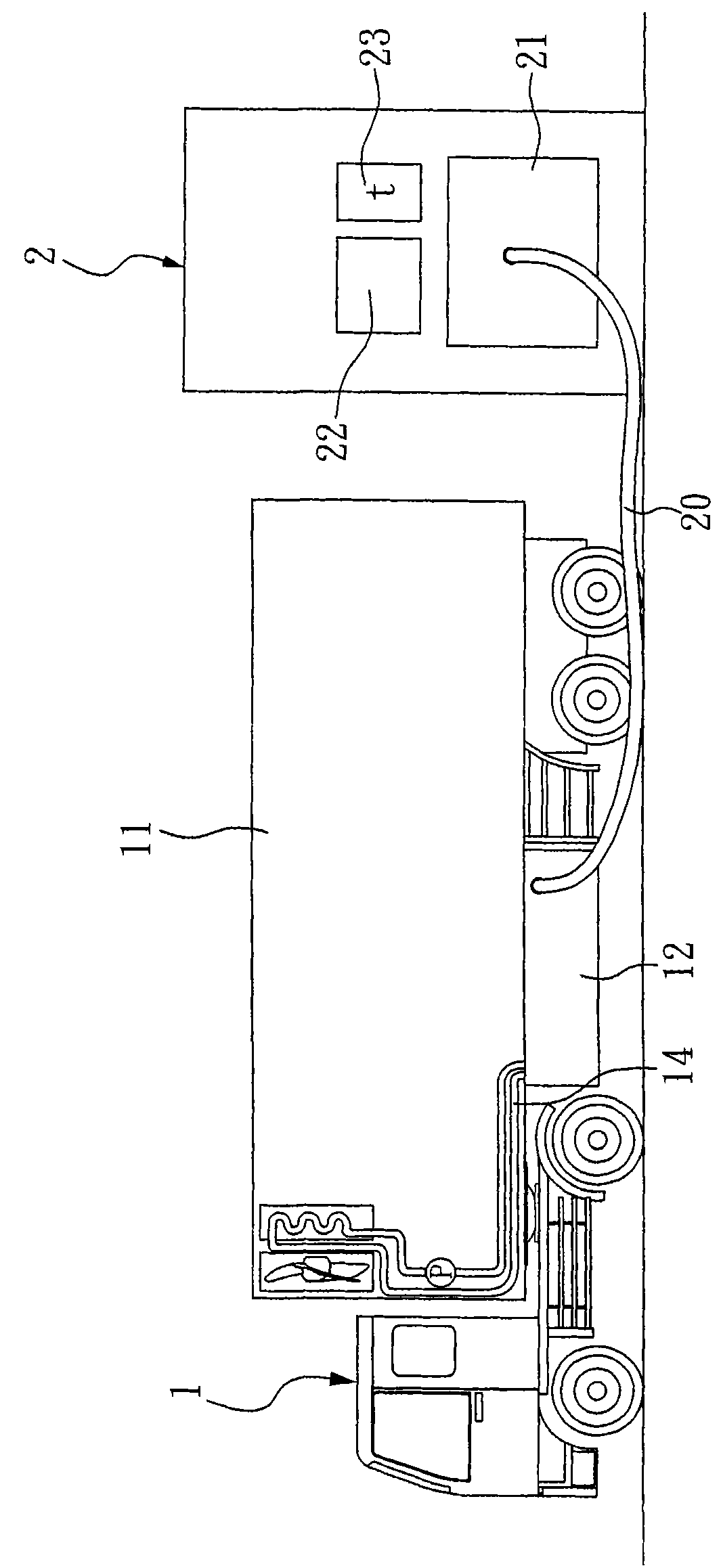

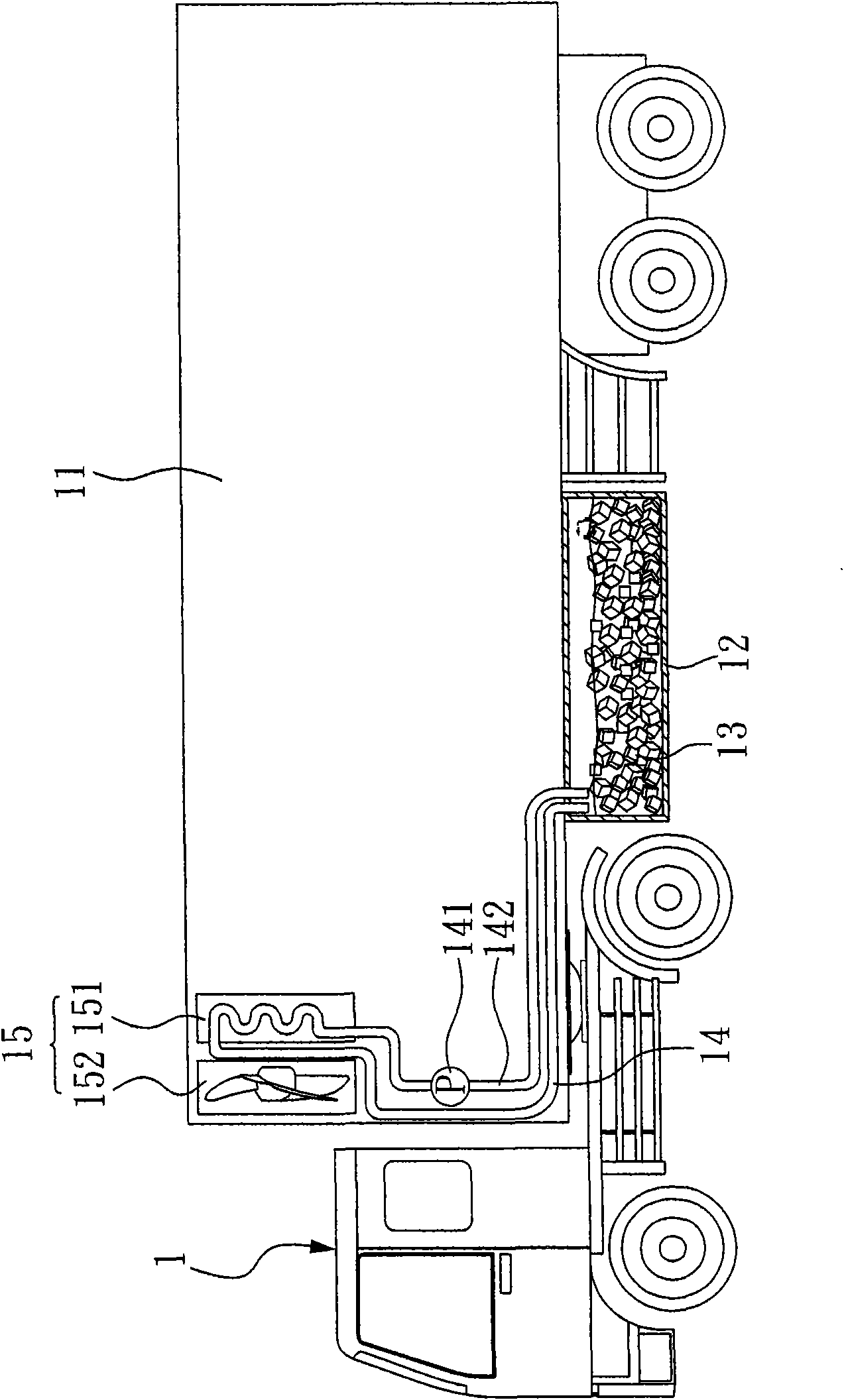

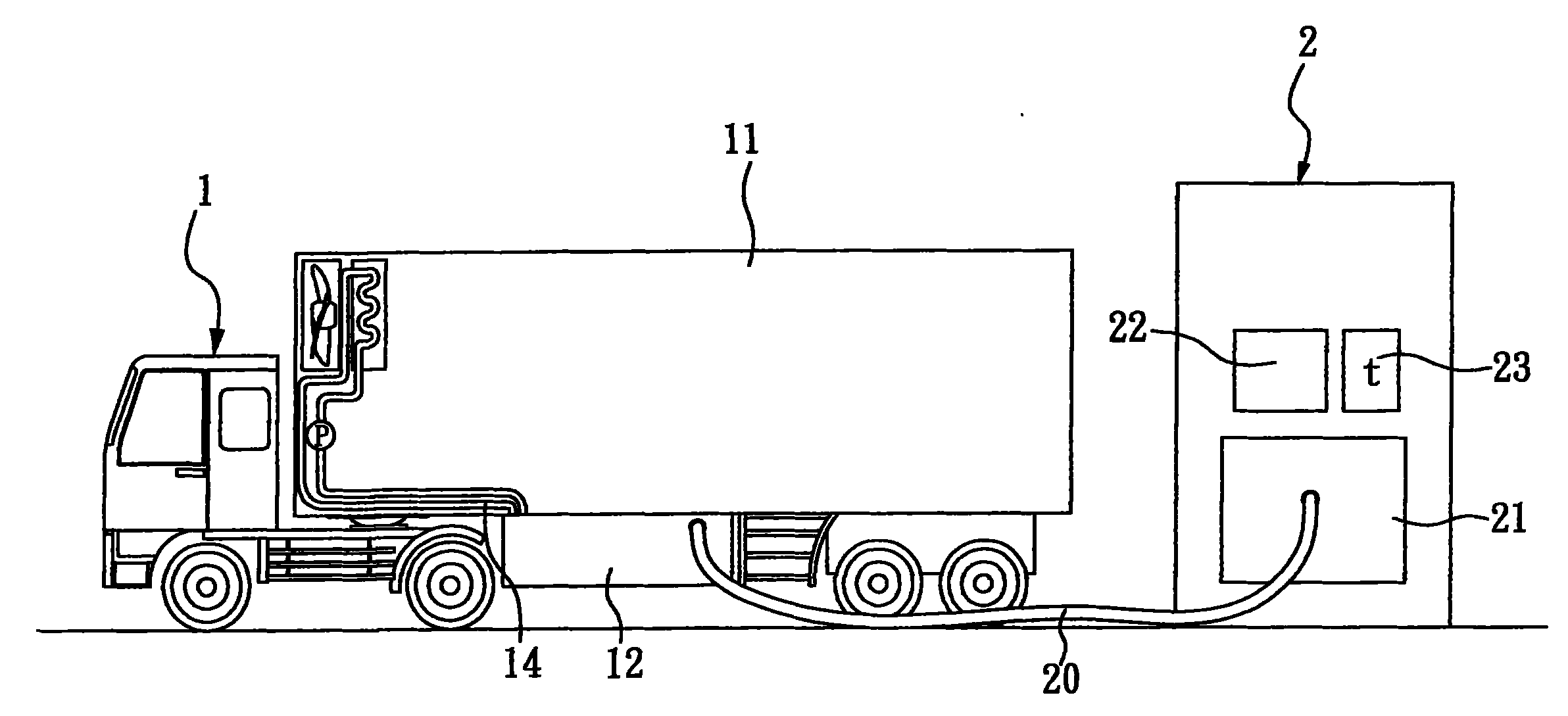

[0018] Please also see figure 1 ,and figure 2 , figure 1 A schematic diagram of a preferred embodiment of the filling type cryogenic logistics system of the present invention, figure 2 It is a schematic diagram of a low-temperature logistics vehicle in a preferred embodiment of the present invention. The figure shows a low-temperature logistics vehicle 1 carrying a low-temperature compartment 11 , a set of circulation pipelines 14 , and a cold storage tank 12 . Wherein, the circulation pipeline 14 is connected to the cold storage tank 12 , and passes through the interior of the low-temperature compartment 11 , and then connects back to the cold storage tank 12 . Moreover, the cold storage tank 12 and the circulation pipeline 14 are filled with a cooling circulation fluid 13 , and the cooling circulation fluid 13 flows and circulates along the circulation pipeline 14 to generate cooling effect. In this embodiment, the cooling circulating liquid 13 is a mixed liquid of ice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com