Method for improving glass strength and reducing strength dispersion by adopting variable-temperature two-step ion exchange and reinforced glass

A technology of strength dispersion and ion exchange, applied in the field of glass reinforcement and reinforced glass, it can solve the problems of high temperature and low glass strength in two-step processing, and achieve the effects of good glass stability, simple processing technology and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

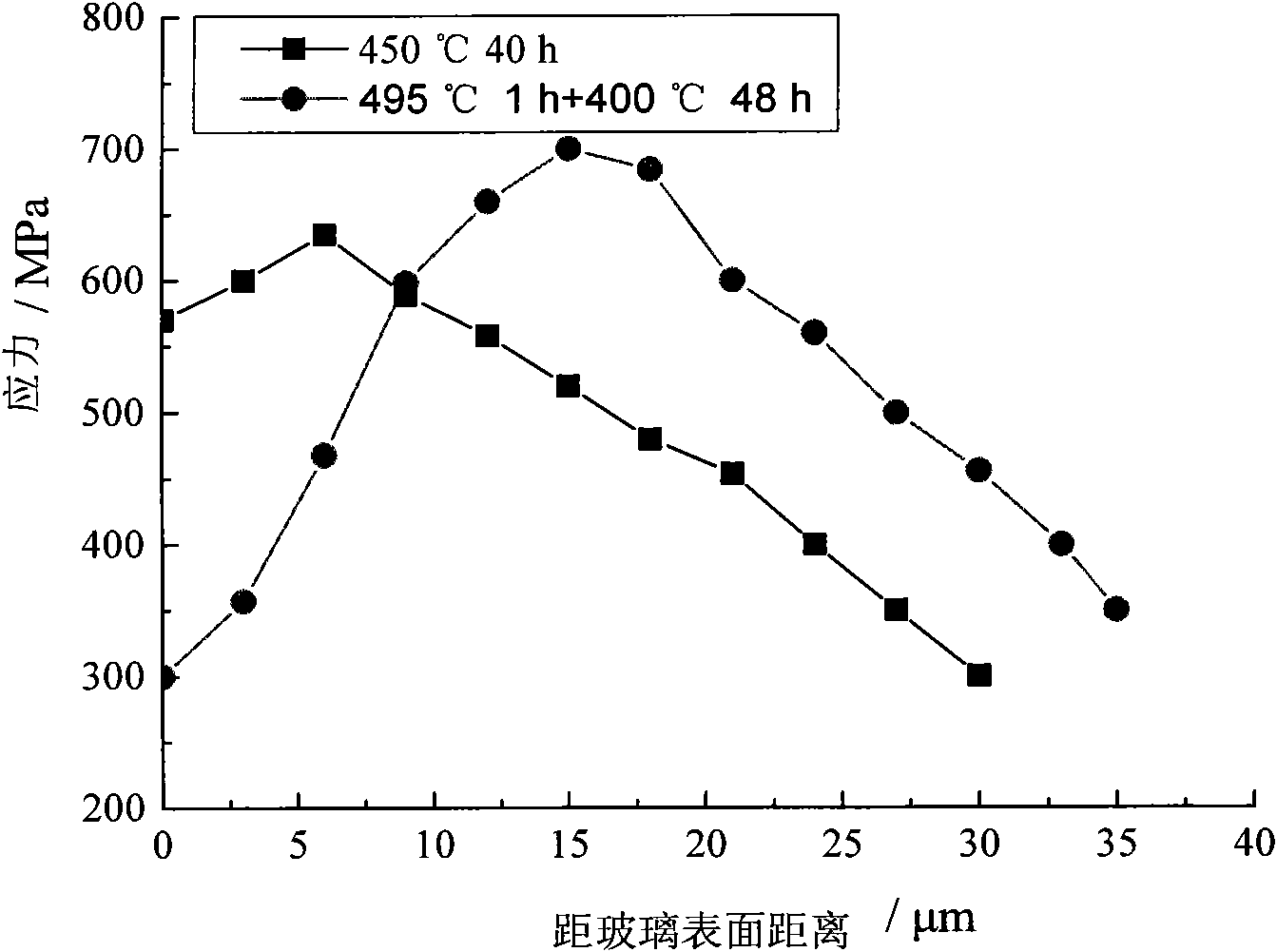

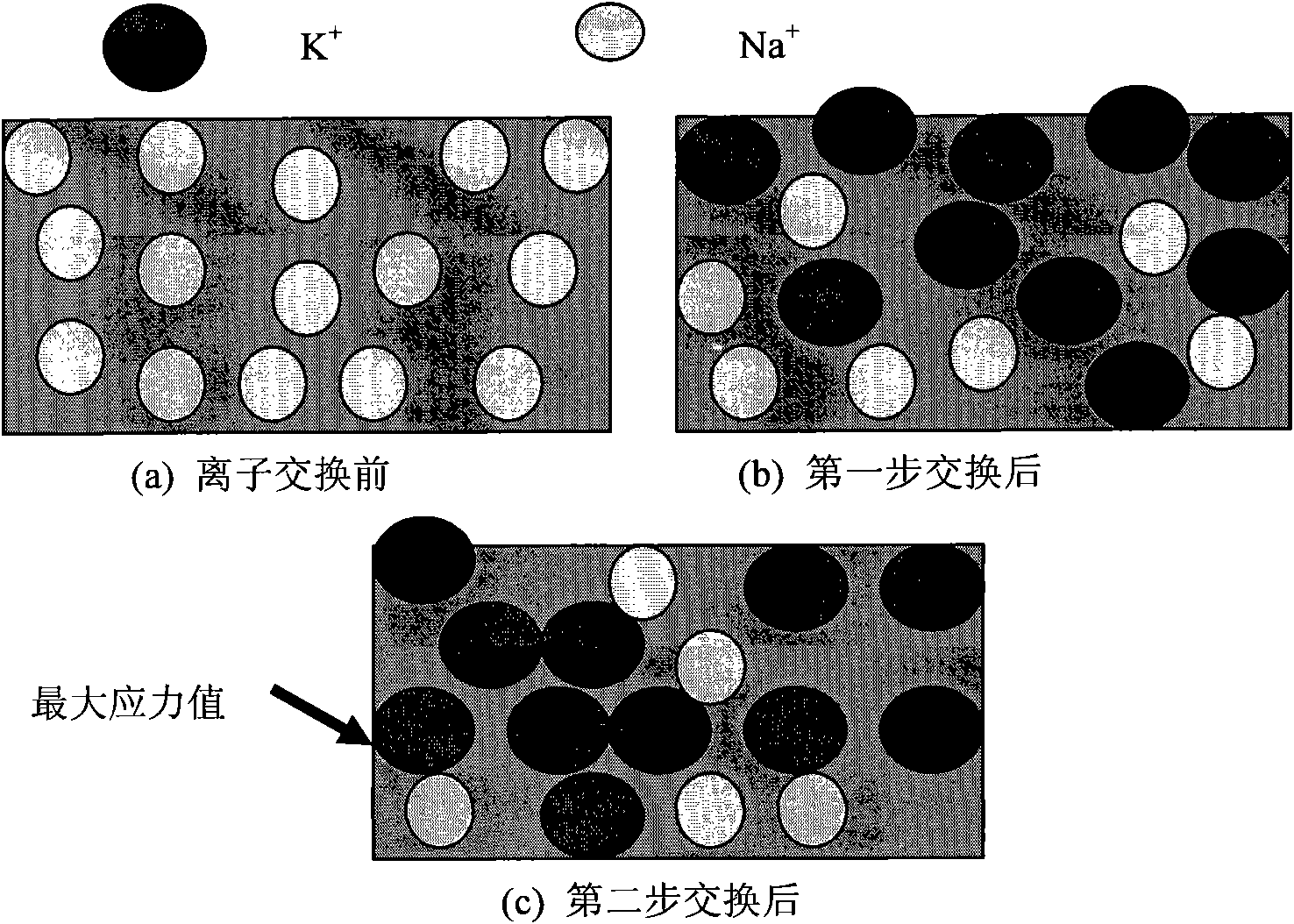

[0017] The invention adopts a two-step temperature-changing ion exchange method to increase the strength of the glass and reduce the dispersion of the glass strength. The variable temperature two-step ion exchange is carried out in a two-slot tempering furnace. Such as figure 1 As shown, the heating temperature difference between the two tanks is achieved by using different arrangement positions of the heating wires. The high temperature tank can realize the change of 450℃~550℃, and the low temperature tank can realize the change of 380℃~450℃. The ion exchange medium consists of 97% commercially pure KNO by weight 3 and 0.5% Al 2 o 3 , 2%K 2 CO 3 , 0.5% KOH is used as an additive composition, which is added to the high temperature tank and the low temperature tank. The original glass sheet undergoes two steps of ion exchange, the first step is high temperature treatment, ion exchange is carried out in a high temperature tank, the temperature range is 490 ° C ~ 510 ° C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com