High-insulation fiber-adding antiflaming blow-molding nylon composite material and preparation method thereof

A nylon composite material with high barrier properties, which is applied in the field of high barrier fiber-added flame-retardant blow-molded nylon composite materials. It can solve the problems that HDPE cannot meet the standards, and ordinary HDPE cannot meet the standards, so as to achieve strong price competitiveness and reduce Possibility of explosion and combustion, light weight effect

Active Publication Date: 2010-12-22

重庆可益荧新材料有限公司

View PDF2 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, high-performance ordinary nylon blow molding materials are only produced by a few multinational companies, such as BASF in Germany, DuPont in the United States, and Rhodia in France. There are no domestic manufacturers

In 2009, the European Union and the United States successively issued regulations, stipulating that the fuel tank of all automobiles, motorcycles, snowmobiles, off-road motorcycles, ATVs, jet skis, boat chainsaws, and lawn / garden equipment should have a fuel penetration rate of no more than 3g / 24 hours. Ordinary HDPE cannot meet EU and US standards at all

With the strict implementation of the ban, HDPE cannot meet the EU and US standards at all

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

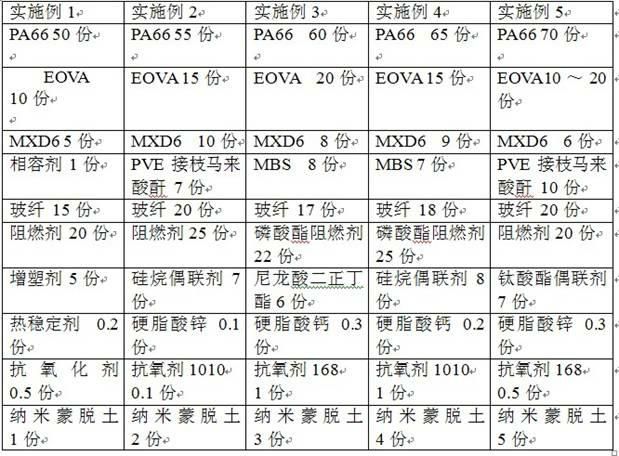

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

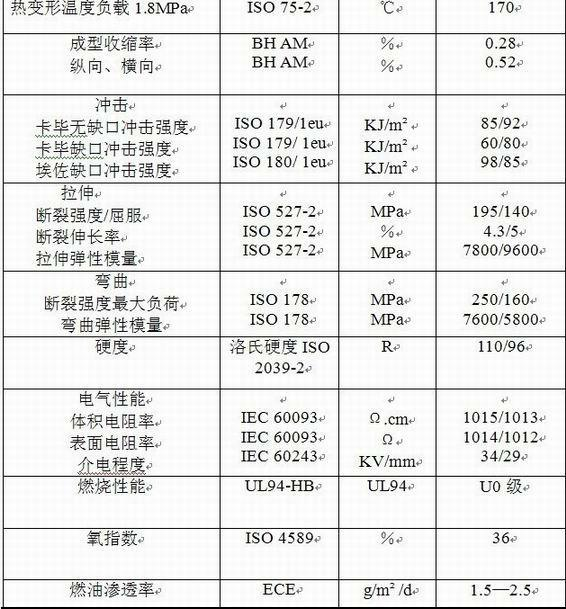

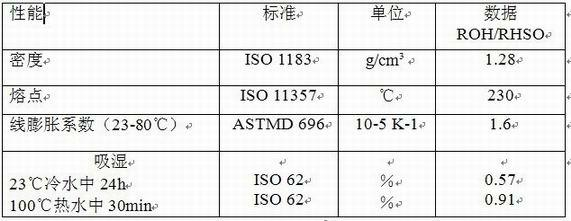

The invention discloses a high-insulation fiber-adding antiflaming blow-molding nylon composite material and a preparation method thereof, wherein the composite material is prepared from the following components in parts by weight: 50-70 parts of PA66, 10-20 parts of EOVA, 5-10 parts of MXD6, 1-5 parts of compatilizer, 15-20 parts of glass fiber, 20-25 parts of flame retardant, 5-10 parts of plasticizer, 0.1-0.3 part of heat stabilizer, 0.1-1 part of antioxidant and 1-5 parts of nanometer montmorillonite. The high-insulation fiber-adding antiflaming blow-molding nylon composite material is prepared by firstly mixing all raw materials in a high-speed machine, and secondly extruding and pelleting the mixed raw materials by a double-screw extrusion pelletizer within the temperature range of 190-250 DEG C. The invention has the advantages of high insulation, high rigidity, high heat resistance, halogen free, fire resistance, single-layer blow-molding, concise and convenient technology and the like; and in addition, the invention greatly reduces the cost and improves the competitiveness in the market on the premise of guaranteeing quality.

Description

technical field The invention belongs to polymer composite materials, and in particular relates to a high-barrier fiber-added flame-retardant blow-molded nylon composite material. Background technique Nylon 11 and 12 are produced by castor oil, which is an environmentally friendly and renewable plastic with good wear resistance, self-lubrication, low temperature resistance, injection molding, extrusion blow molding, and good barrier properties. But the price is five times that of ordinary nylon, 100,000 RMB / ton. It is mainly used in automobile fuel pipes and brake pipes, and its high price limits the application range of PA11 and PA12. Ordinary nylon is its main application variety. PA6 and PA66 account for more than 80% of the nylon market, about 20,000 RMB / ton. Ordinary nylon has obvious price advantages, but also has disadvantages, such as high water absorption, poor low temperature performance, poor creep resistance, large molding shrinkage, low melt viscosity of homop...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L77/06C08L23/08C08L29/04C08L51/00C08K13/06C08K9/06C08K7/14C08K3/34

Inventor 咸旭胜

Owner 重庆可益荧新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com