Bioreactor for producing microbial cellulose and method thereof

A microbial cellulose and bioreactor technology, applied in the direction of microorganism-based methods, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., can solve problems such as production efficiency and unsatisfactory molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

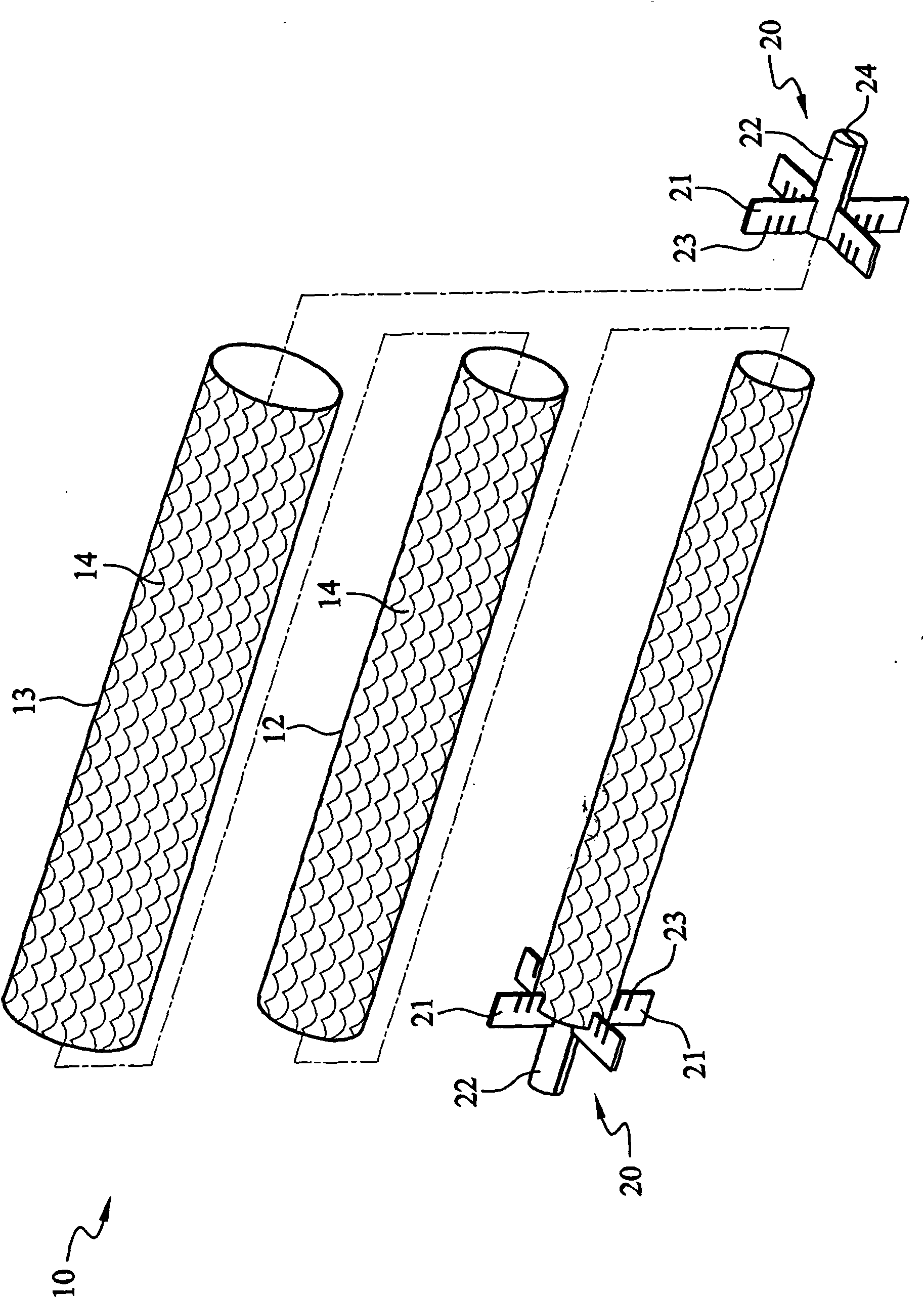

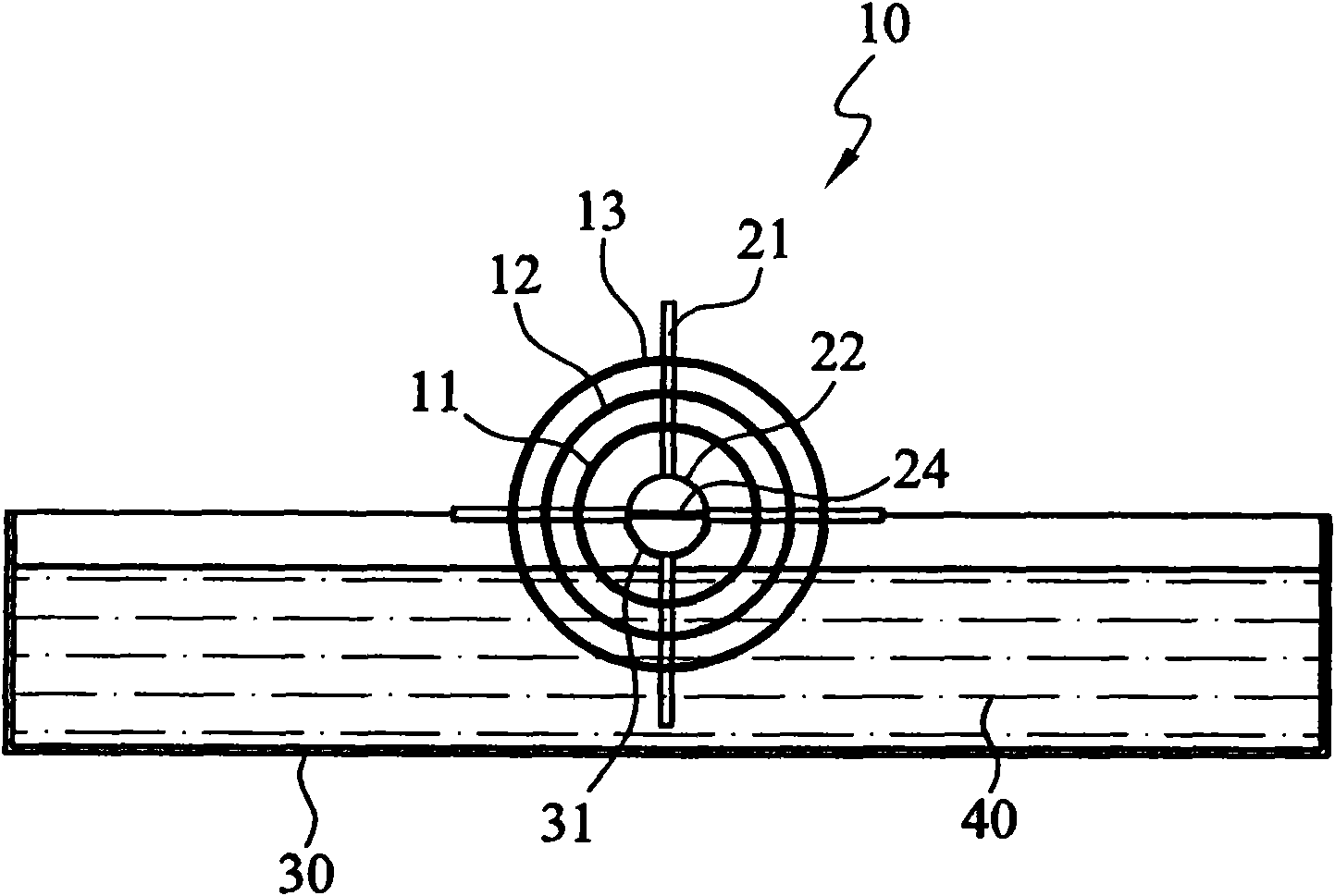

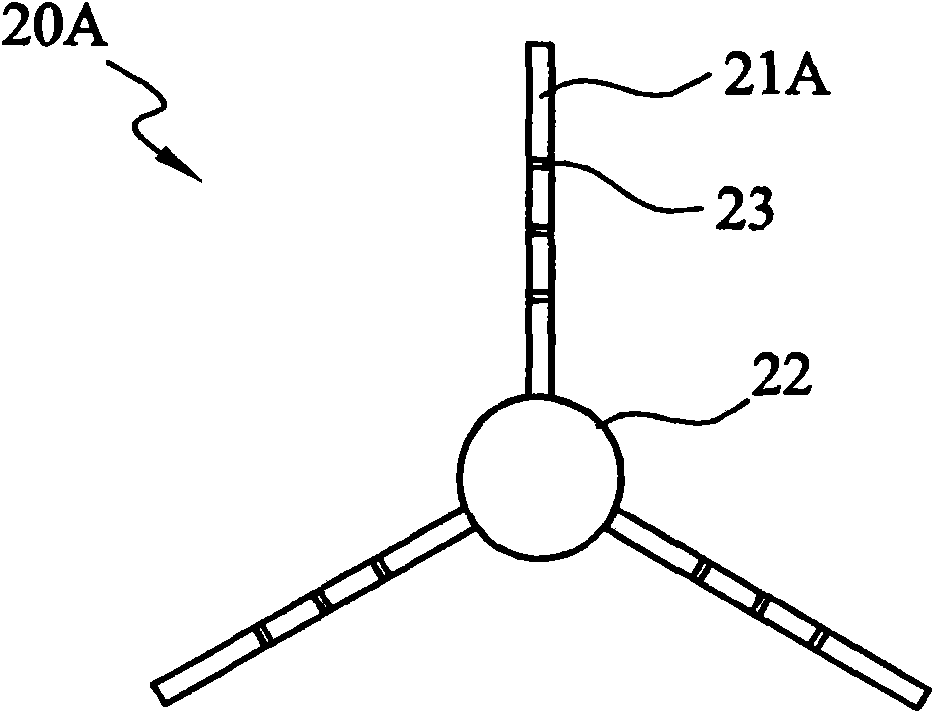

[0055] Example 1: A single set of three hollow tubes fitted together

[0056] This example uses figure 1 and figure 2 In the bioreactor shown, the vessel 30 has dimensions of 33 cm long x 23 cm wide x 4 cm high, and the three hollow tubes 11-13 have a length of 30 cm. A motor drives the rotating shaft 22 to rotate at a speed of 10 rpm, that is, the horizontal mold set 10 rotates horizontally at a speed of 10 rpm.

[0057] The bioreactor is placed in an environment free of bacteria contamination for microbial cultivation, wherein the height of the microbial cultivation liquid medium 40 in the container 30 is 35mm, and the cultivation temperature is 30°C. The culture liquid medium 40 is pre-prepared shaking culture liquid. The pre-oscillation culture solution is a liquid medium containing the ingredients listed in the following table and a bacterial cell concentration of 5%, which is filled with xylogluconate obtained by culturing at 120rpm and 30°C for two days under the co...

Embodiment 2

[0061] Embodiment 2: a single set of two nested hollow tubes

[0062] This embodiment repeats the steps of Example 1 and the bioreactor used, except that the second hollow tube (diameter 40 mm) of the three hollow tubes is not used.

[0063] The present embodiment obtains 1.745g / L sheet-like bacterial cellulose in the undisturbed part, while the horizontal mold set part obtains a total of two tubular bacterial cellulose of 1.815g / L, and the total output is 3.56g / L.

Embodiment 3

[0064] Embodiment 3: Single hollow tube

[0065] This embodiment repeats the steps of Example 1 and the bioreactor used, except that the first hollow tube (diameter 30mm) and the second hollow tube (diameter 40mm) of the three hollow tubes are not used. .

[0066] The present embodiment obtains 1.745g / L flake bacterial cellulose body in the undisturbed part, and a tubular bacterial cellulose body of 0.77g / L is obtained in the horizontal mold set part, and the total output is 2.515g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com