X70QS seamless line pipe with HIC (Hydrogen Induced Cracking) resistance

A seamless line pipe and performance technology, applied in the field of corrosion-resistant materials and seamless pipes, can solve the problems of wide composition range and no clear steel grade, and achieve the effect of high strength, good HIC resistance and high ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

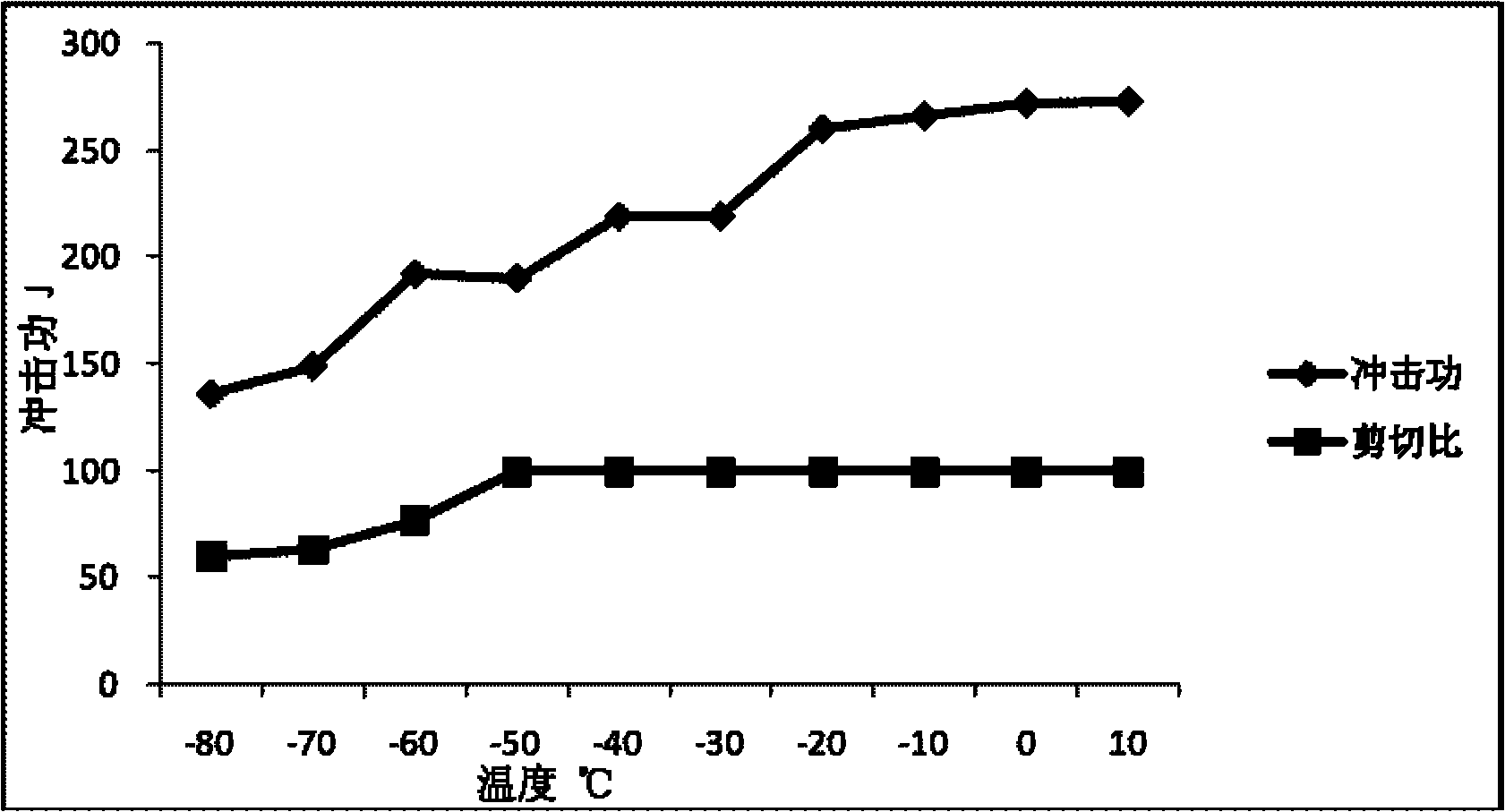

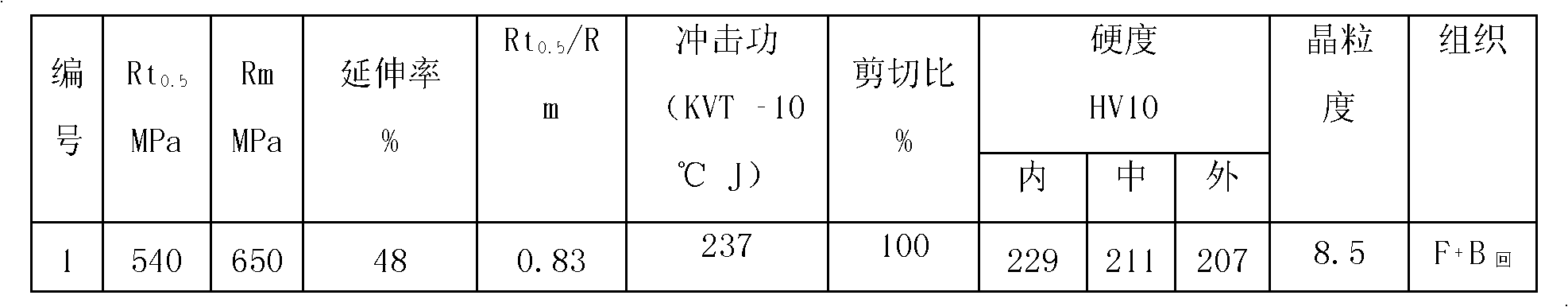

[0009] The X70QS seamless line pipe with anti-HIC performance of the present invention will be described with reference to the drawings and examples.

[0010] In the X70QS seamless line pipe with HIC resistance of the present invention, the composition weight percent of the seamless line pipe is C 0.06-0.14%, Si 0.20-0.45%, Mn 1.00-1.30%, P≤0.015%, S≤0.003 %, Ni≤0.10%, Cu≤0.20%, Cr 0.05~0.30%, Mo 0.05~0.30%, Al 0.015~0.060%, N 0.003~0.010%, Nb 0.030~0.050%, V0.05~0.09%, Ca ≤0.060%, the balance is Fe and impurities; carbon equivalent CEpcm≤0.22%, CE IIW ≤0.39%.

[0011] Cr and Mo in the composition are alloying elements and V and Nb are microalloying elements, and the addition amount is Cr+Mo≥0.15%, Cr+Mo+Mn≤1.80%, V+Nb≥0.09%.

[0012] It has good HIC resistance under yield strength ≥ 485MPa, crack sensitivity rate CSR ≤ 2%, crack length rate ≤ 10%, crack thickness rate CTR ≤ 3%.

[0013] The specific optimized chemical composition of the present invention is described as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com