Shoveling apparatus with multi-positional shovel

A technology of equipment, buckets, applied in ground mining, slitting machinery, loading/unloading, etc., which can solve the problems of time and money, danger, laborious corridors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

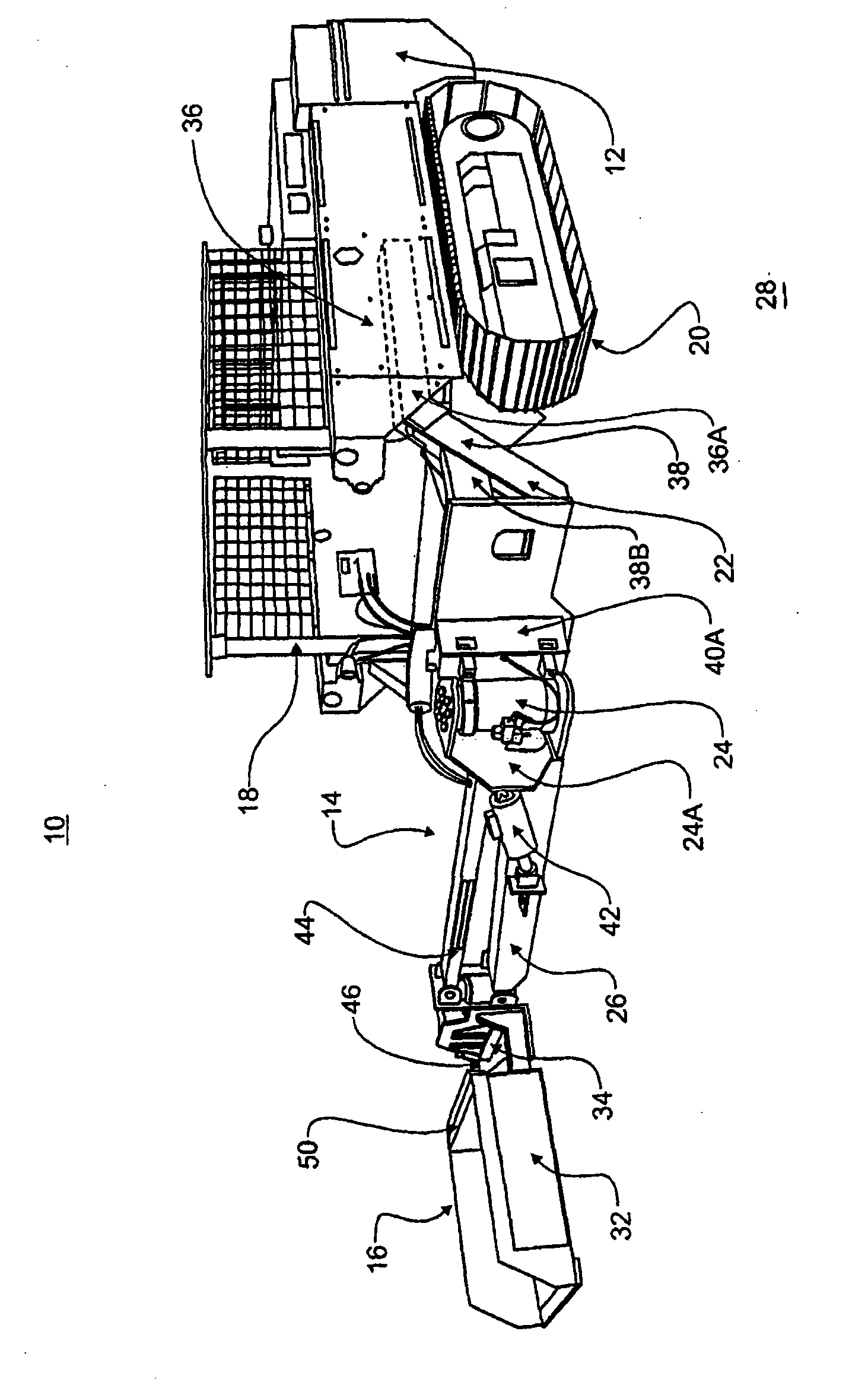

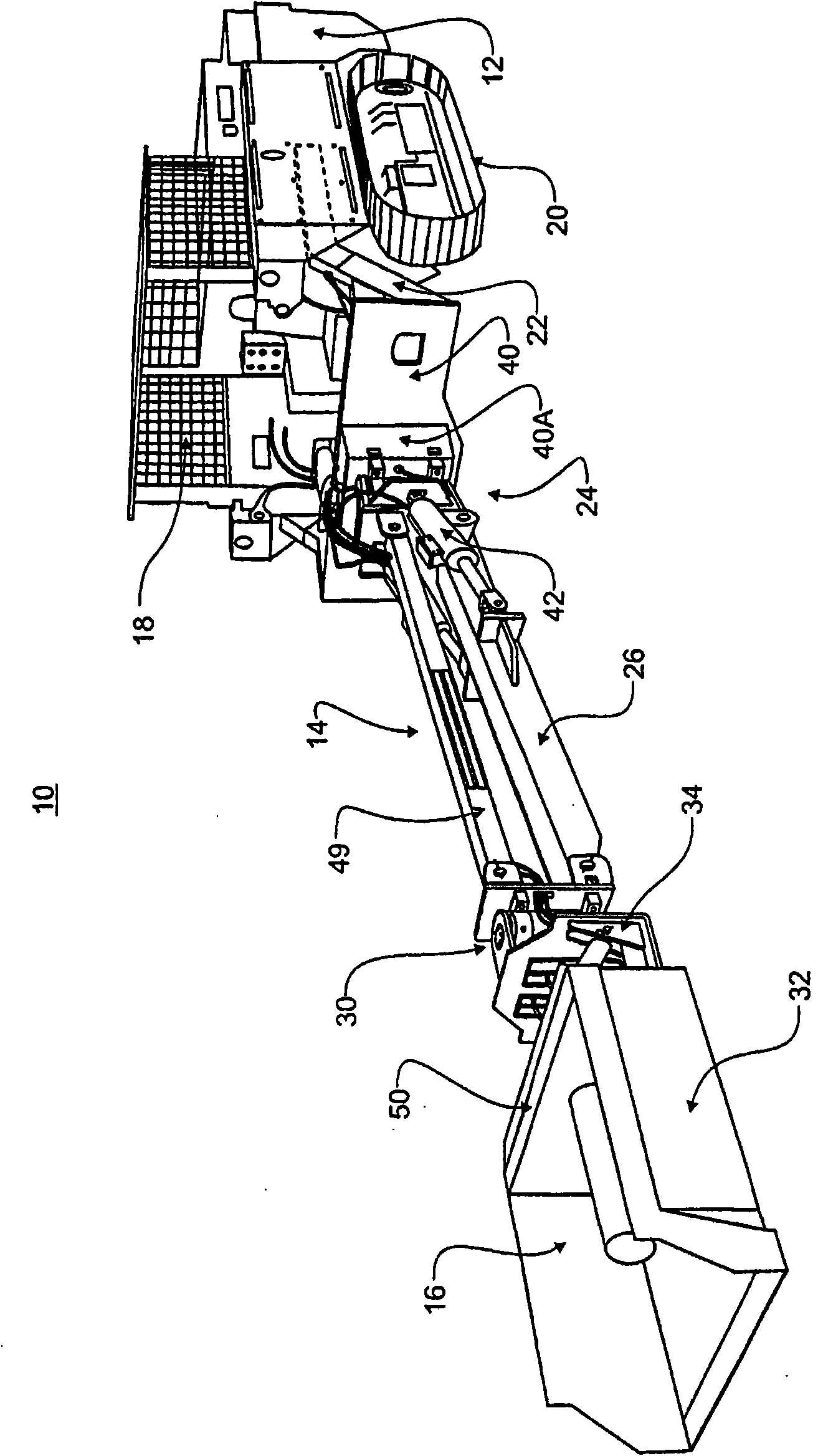

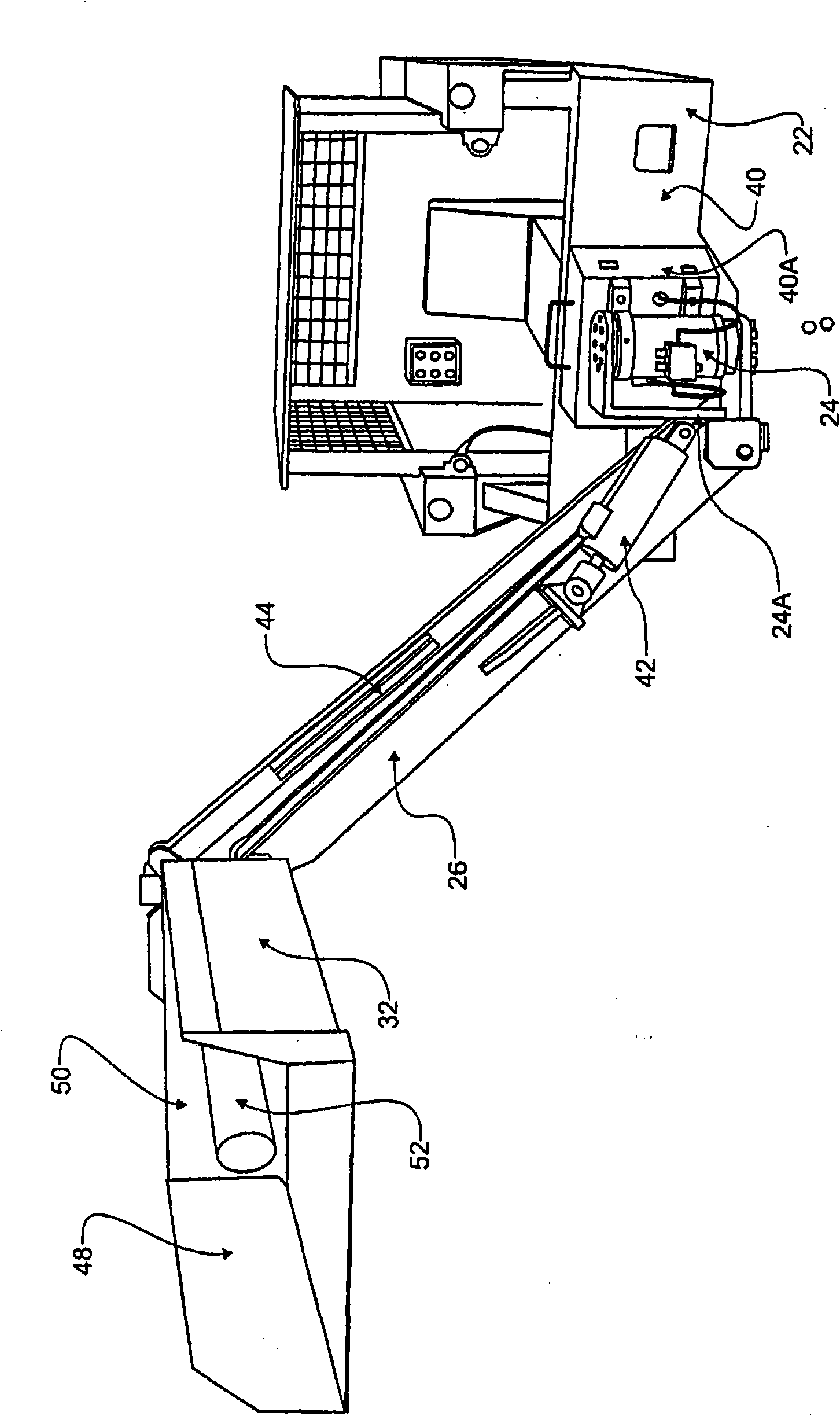

[0019] First refer to figure 1 An embodiment of a shoveling apparatus 10 includes a low profile vehicle 12, a boom assembly 14, and a bucket assembly 16, respectively. These components 12, 14, 16 of the shoveling apparatus 10 cooperate to shovel coal and rock from near and under the coal seam of an underground coal mine and dump the cuttings on a coal conveyor for transport out of the mine.

[0020] Such as Figure 1-3 As shown, the low profile vehicle 12 includes a cab portion 18 , one or more kinematic supports 20 and propulsion supports 22 . Cab portion 18 provides a space for an operator of shovel equipment to work in vehicle 12 and typically includes a cab or other protective enclosure or portion of an enclosure to provide protection for the operator from damage caused by foreign objects that may fall on the vehicle. harm. Typically, an operator is able to control the low profile vehicle 12 , boom assembly 14 and bucket assembly 16 within the cab portion of the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com