A kind of recycling method of electroplating waste slag

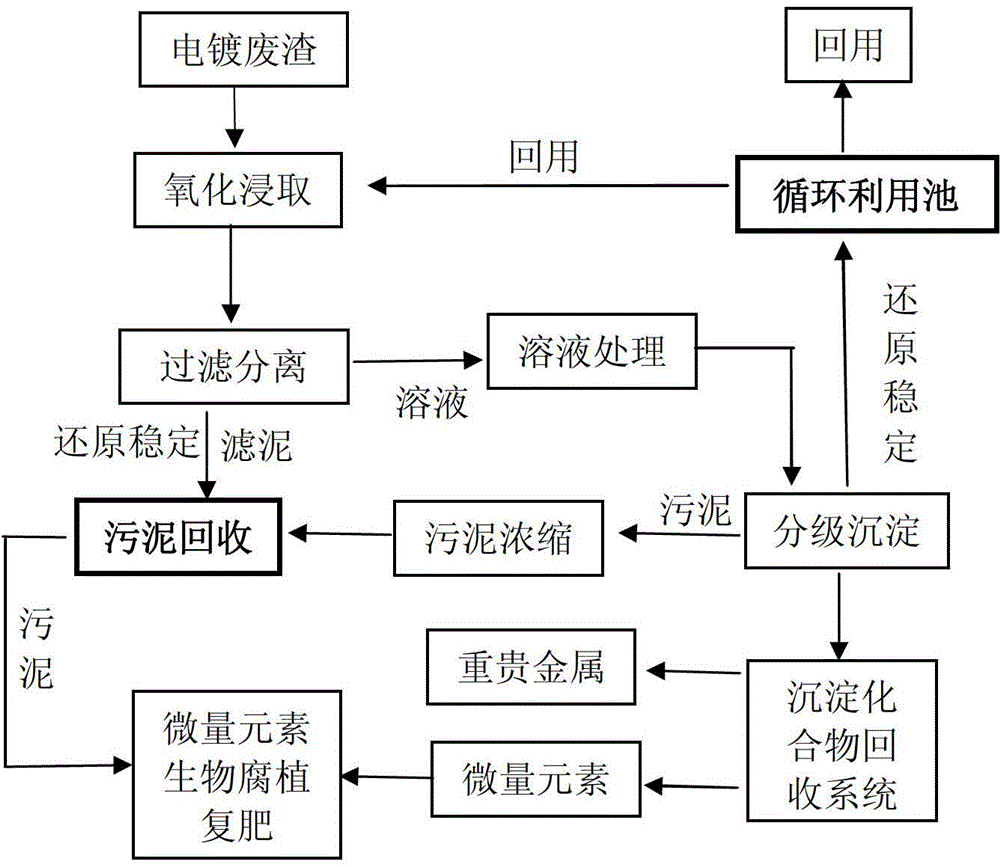

A technology for electroplating waste residue and leaching, which is applied in the field of electroplating waste residue recycling, can solve the problems of inability to form a systematic recycling system, narrow application range, single use, etc., and achieves the realization of circular economic benefits, reduction of recycling costs, labor and labor savings. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

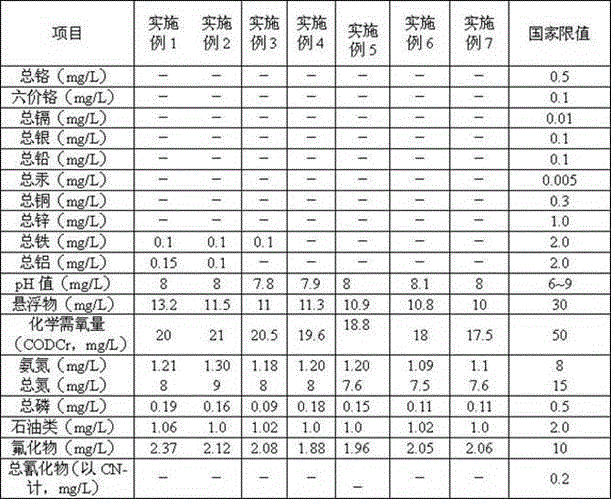

Embodiment 1

[0024] (1) Oxidative leaching: Soak electroplating waste residue and water for 4~5 hours according to the ratio of solid to liquid volume of 1:8, and add sodium hypochlorite in aeration at the same time, and the air flow rate is 0.9m 3 / min, the amount of sodium hypochlorite is 0.8% of the weight of the electroplating waste residue, and the stirring speed is 200rmp, so that the pollutants are converted into water-soluble compounds and dissolved into the water phase. The pH value in the dissolution reaction tank is controlled between 8 and 9, and the heavy metal ions in the waste residue Converted into water-soluble carbonates and hydroxides, after the oxidation leaching process is completed in the dissolution reaction tank, the oxidation leaching slurry is obtained. The dissolution reaction tank is an underground device, which is convenient for using a forklift to directly shovel the sludge waste and feed into the reactor, saving labor and power.

[0025](2) Filtration and...

Embodiment 2

[0030] (1) Oxidative leaching: Soak electroplating waste residue and water for 3~4 hours according to the ratio of solid to liquid volume of 1:9, and add redox agent hydrogen peroxide with aeration at the same time, and the air flow rate is 0.6m 3 / min, the amount of hydrogen peroxide is 0.5% of the weight of the electroplating waste residue, and the stirring speed is 250rmp, so that the pollutants are converted into water-soluble compounds and dissolved into the water phase, and the pH value in the dissolution reaction tank is controlled between 8 and 9. The heavy metal ions are converted into water-soluble carbonates and hydroxides, and after the oxidation leaching process is completed in the dissolution reaction tank, the oxidation leaching slurry is obtained. The dissolution reaction tank is an underground device, which is convenient for using a forklift to directly shovel the sludge waste and feed into the reactor, saving labor and power.

[0031] (2) Filtration a...

Embodiment 3

[0036] (1) Oxidative leaching: Soak electroplating waste residue and water for 4~5 hours according to the ratio of solid to liquid volume of 1:6, and add redox agent hydrogen peroxide with aeration at the same time, and the air flow rate is 0.8m 3 / min, the amount of redox agent is 1.2% of the weight of electroplating waste residue, and the stirring speed is 900rmp, so that the pollutants are converted into water-soluble compounds and dissolved into the water phase, and the pH value in the dissolution reaction tank is controlled between 8~9. The heavy metal ions are converted into water-soluble carbonates and hydroxides, and after the oxidation leaching process is completed in the dissolution reaction tank, the oxidation leaching slurry is obtained. The dissolution reaction tank is an underground device, which is convenient for using a forklift to directly shovel the sludge waste and feed into the reactor, saving labor and power.

[0037] (2) Filtration separation: Sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com