Method for recycling vinasse

A technology of distiller's grains and liquor, which is applied in the recovery of by-products, the preparation of alcoholic beverages, biochemical equipment and methods, etc., to achieve the effect of increasing economic value and realizing circular economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

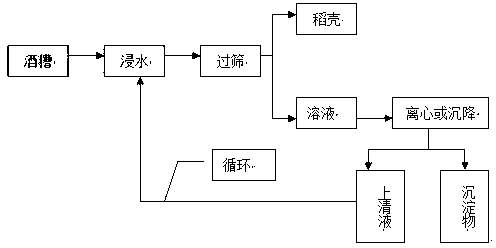

[0060] This embodiment illustrates the preparation method of the distiller's grain suspension and the separation and recovery method of the complete rice husk of the present invention, see figure 1 shown.

[0061] Some process parameters for the establishment and separation of distiller's grain suspension were determined through single factor experiments: when the mass ratio of solid to liquid is 1:2, the soaking time is 30 minutes, the number of washings is 6 times, the aperture of the sieve is 1mm, and the centrifugal speed is 3000r / min, and the centrifugation time is 15min, the establishment and separation process of distiller's grain suspension can be completed.

[0062] The separated rice husks and fresh rice husks were compared and analyzed under a microscope, and it was found that the recycled rice husks were darker in color, while the fresh rice husks were golden yellow and brighter in color. However, the structure of the recovered rice husk is still relatively comp...

Embodiment 2

[0069] This example illustrates the application of recycled rice husks in liquor fermentation.

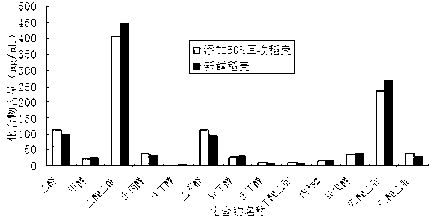

[0070] After mixing the recovered rice husk and fresh rice husk evenly according to the mass ratio of 1:1, they are re-added to the fermentation process of liquor to produce liquor; half of the fermentation raw materials come from recycled rice husk, other raw materials and The conditions of the fermentation process are all the same as the original liquor fermentation conditions.

[0071] Due to the variety, quality and starch content of wine-making raw materials, it has a great influence on the stability and comparability of wine yield. Therefore, the alcohol yield of raw grain cannot be used as the basis for assessment, but the alcohol yield of standard raw grain should be assessed. The specific requirements and practices are as follows:

[0072] (1) Standard raw grains: raw grains, mainly including grains for brewing wine, yeast grains and residual starch in Daqu (excluding br...

Embodiment 3

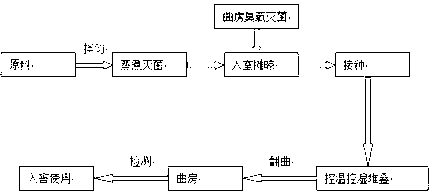

[0085] This example illustrates the method of recycling rice husks to produce bran yeast.

[0086] Wheat bran: rice husk = 95:5 (mass ratio) for the production of bran koji. The production method is: 3 kinds of bacteria are required for the bran koji, namely Hanoi white koji, Bacillus subtilis, and lipogenic yeast (all purchased from ATCC ), which were cultured with single strains and finally made into bran koji and mixed in a certain proportion for use. A. Hanoi white koji: Selected combination medium: add water at a ratio of 1:1, stir evenly, autoclave at 121°C for 1 hour, cool to 35°C, add seed koji at 2%, mix evenly, Keep the room ventilated, the humidity is 95%-100%, the culture temperature is 35°C, and the culture time is about 72 hours. B. Bacterial gluten koji: After fermentation, it can produce the characteristic aroma of typical sesame-flavored liquor. Add water according to the ratio of selected combination medium: water = 1:1, autoclave at 121°C and cool to 37°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com