Waste oil and water conveying device for compressed air station

A technology of compressed air and conveying device is applied in the field of waste oil and water collection devices, which can solve the problems of inability to pump oil and water in pipelines, small waste oil discharge, inconvenient operation and operation, etc., so as to save construction workload, reduce pressure, and obtain gas. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

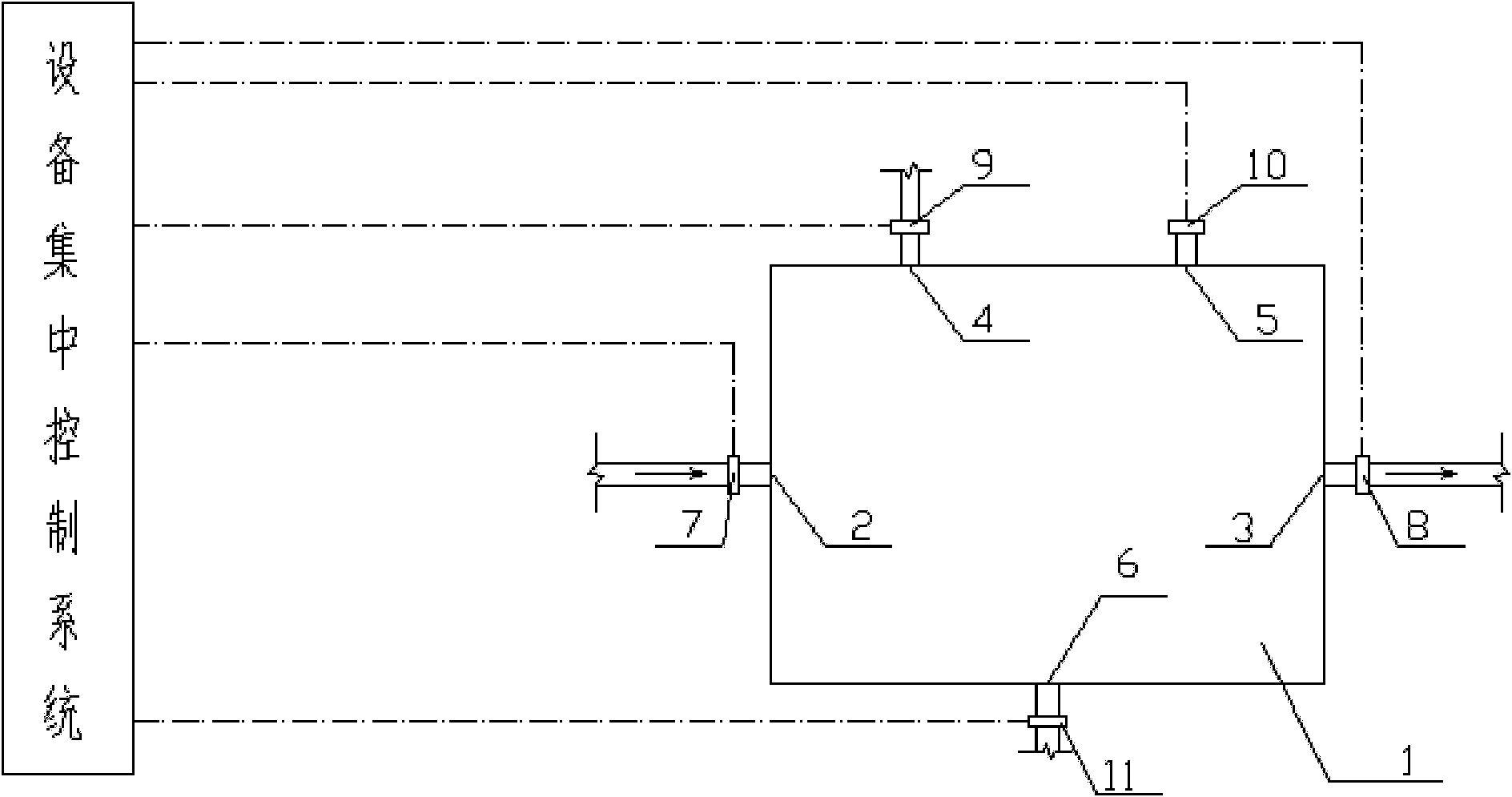

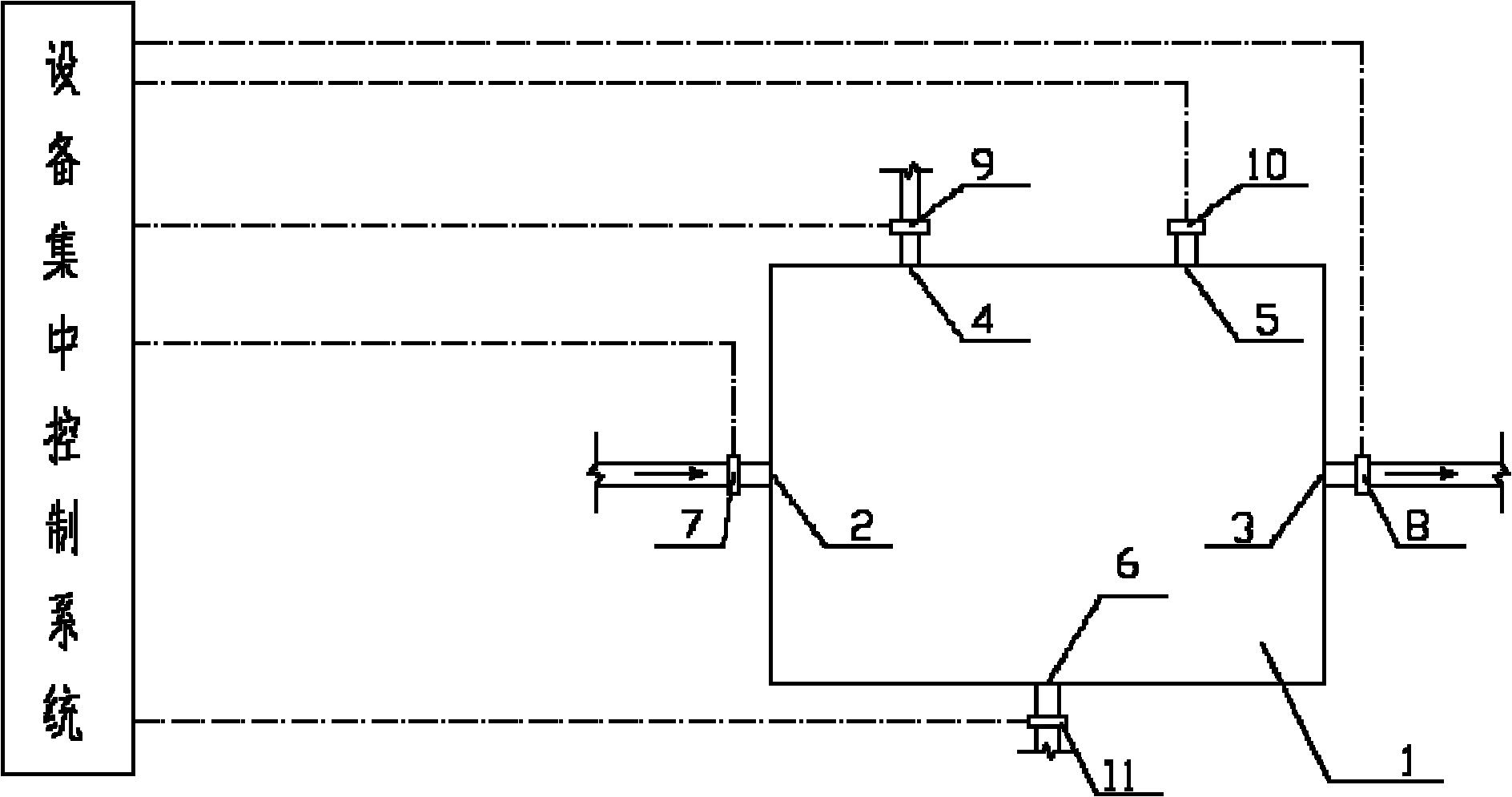

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] see figure 1 , a compressed air station waste oil water delivery device, it includes a storage container 1, the storage container is made of C20# steel, cylindrical shape, nominal diameter can be selected DN350mm. The two ends of the storage container are respectively provided with an oil inlet 2 and an oil outlet 3, and the top of the storage container is also provided with a compressed air inlet 4 and a liquid level gauge installation interface 5, and a sewage outlet 6 is provided at the bottom of the storage container. There is a first electric valve 7, the specific model can choose PN1.6, DN40mm, there is a second electric valve 8 at the oil outlet, the specific model can choose PN1.6, DN32mm, there is a third electric valve at the compressed air inlet Valve 9, the specific model can choose PN1.6, DN32mm, the liquid level gauge installation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com