Solid material transporting elbow with detachable and changeable liner

A technology for solid materials and elbows, applied in elbows, siphons, pipe components, etc., can solve the problems of short service life and poor anti-wear performance, and achieve convenient replacement and maintenance, good impact wear resistance, and shortened maintenance time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

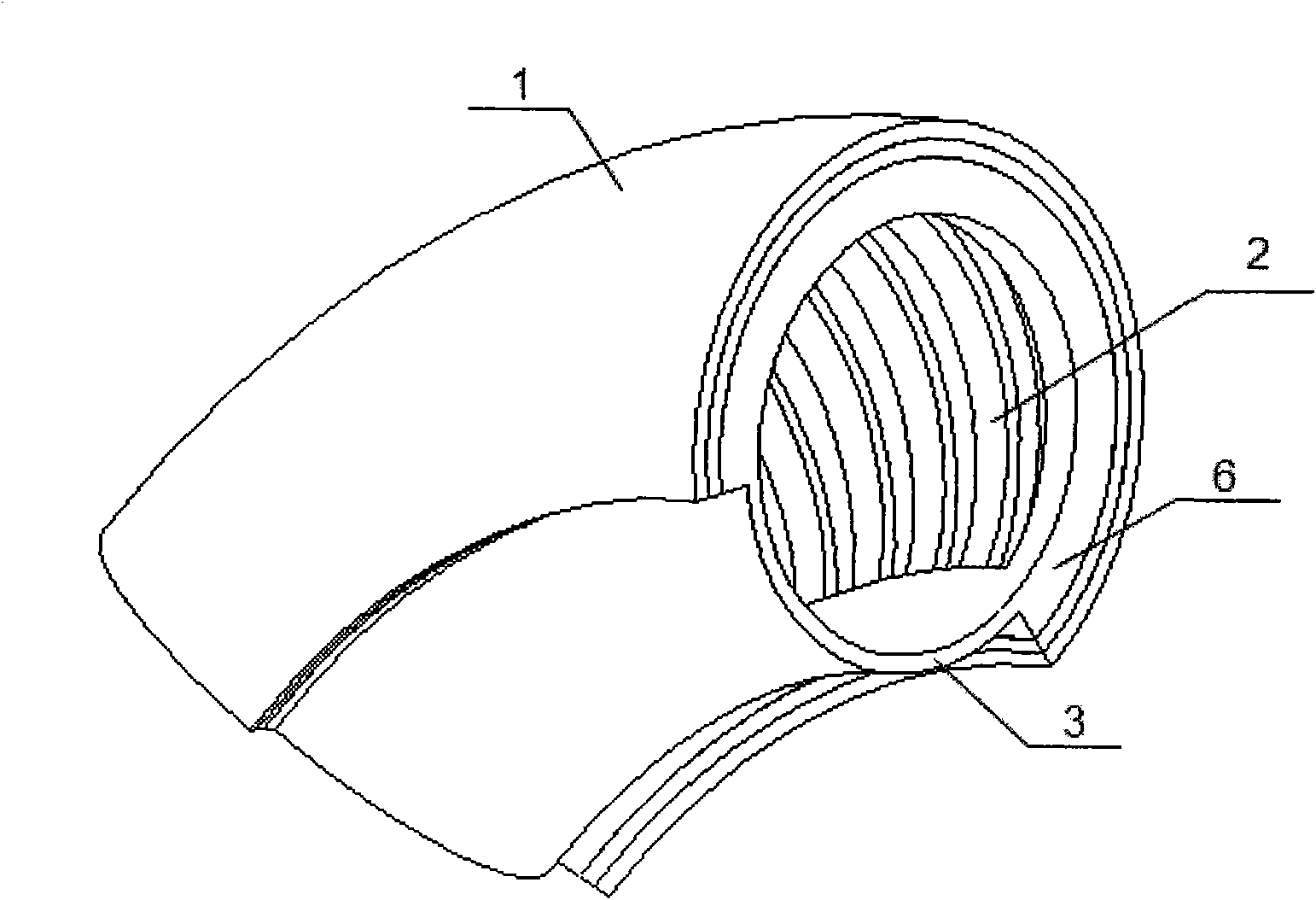

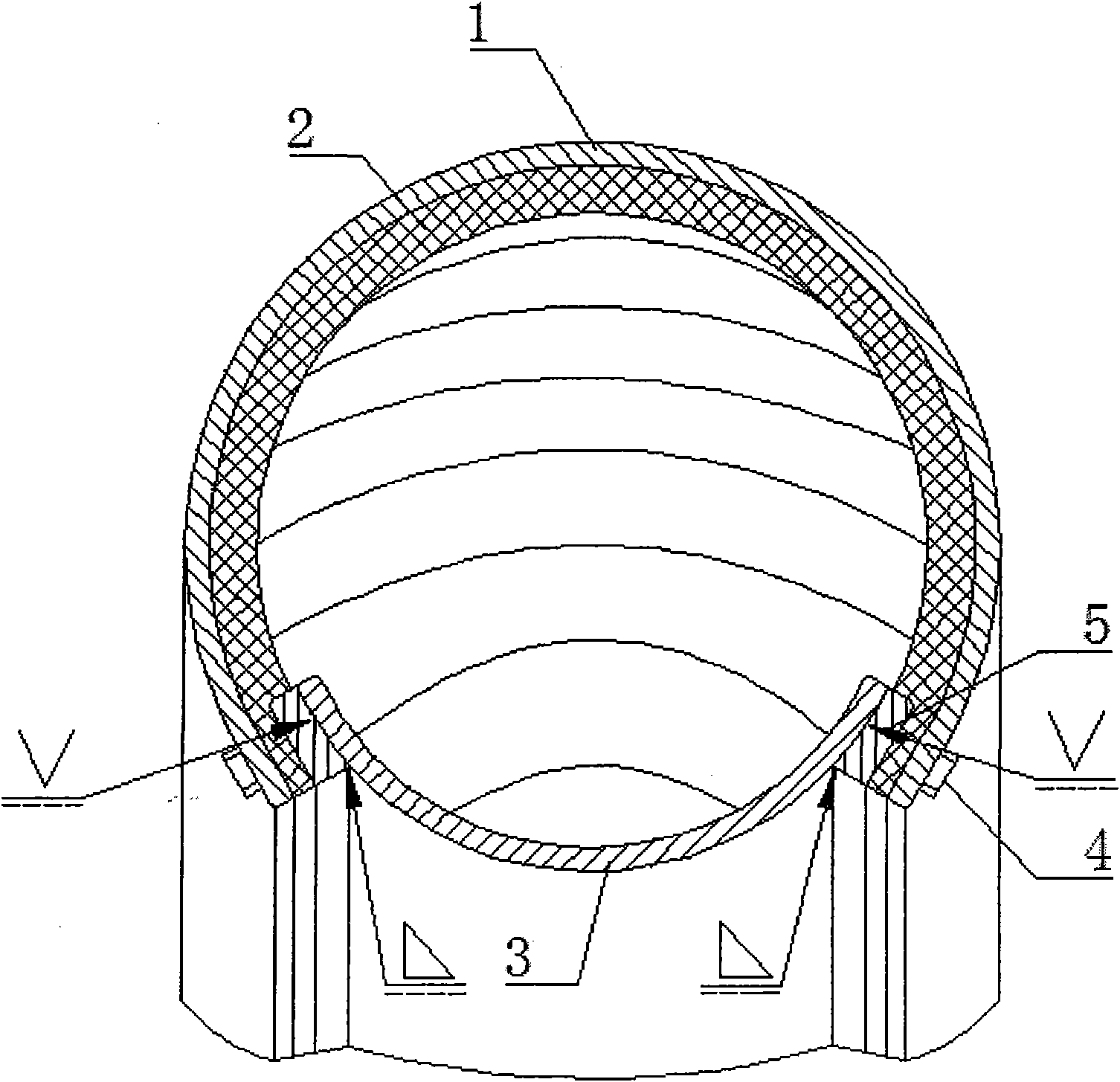

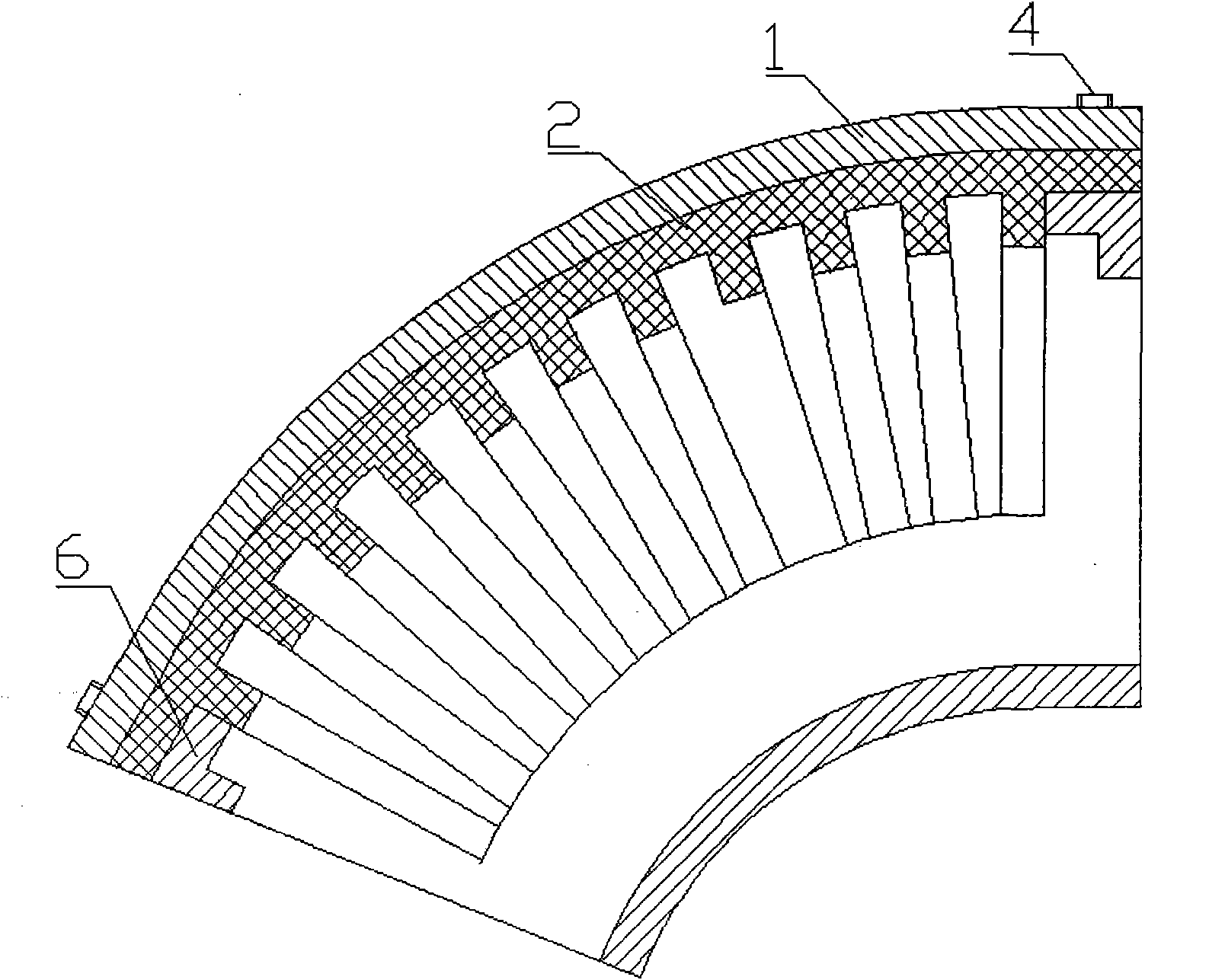

[0013] Such as figure 1 , figure 2 and image 3 As shown, expand the pipe diameter within the range of 45°~145° of the elbow 3, open a hole, and install a composite cover plate with the same curvature as the bend pipe at the hole. The composite cover plate is lined with patterned textured rubber 2 It is composed of a cover plate 1 that is closely attached to the outer periphery of the inner liner 2; in this embodiment, the inner diameter of the inner liner 2 is equal to the outer diameter of the elbow 3. The bent pipe 3 has the same pipe diameter as the connected straight pipe. The patterned textured rubber lining 2 has the same bending rate as the elbow, and the surface is regularly arranged patterned textures, and the material can be natural hard rubber, butyl rubber, neoprene rubber, nitrile rubber, etc. The patterned texture can be grooved, meshed, dotted, etc. In this embodiment, the rectangular groove-like texture is taken as an example, and the size can be adjusted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumferential angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com