Inductive energy-storage microsecond-grade high-power pulse current source

A high-power pulse, microsecond-level technology, applied in the field of current source, can solve the problems of pulse width limited to millisecond level and response time of hundreds of microsecond level, which cannot satisfy fast pulses, etc., and achieve good constant current characteristics, lead Arc and Constant Current Ultra-Fast Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

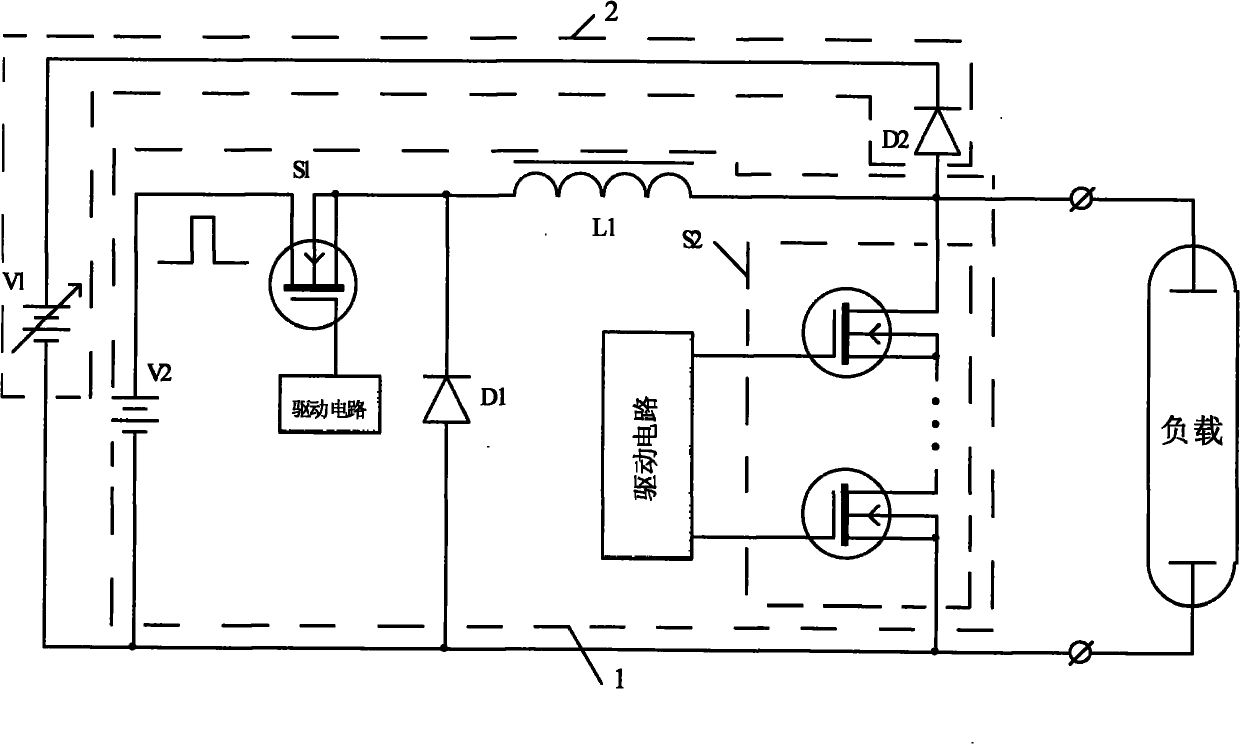

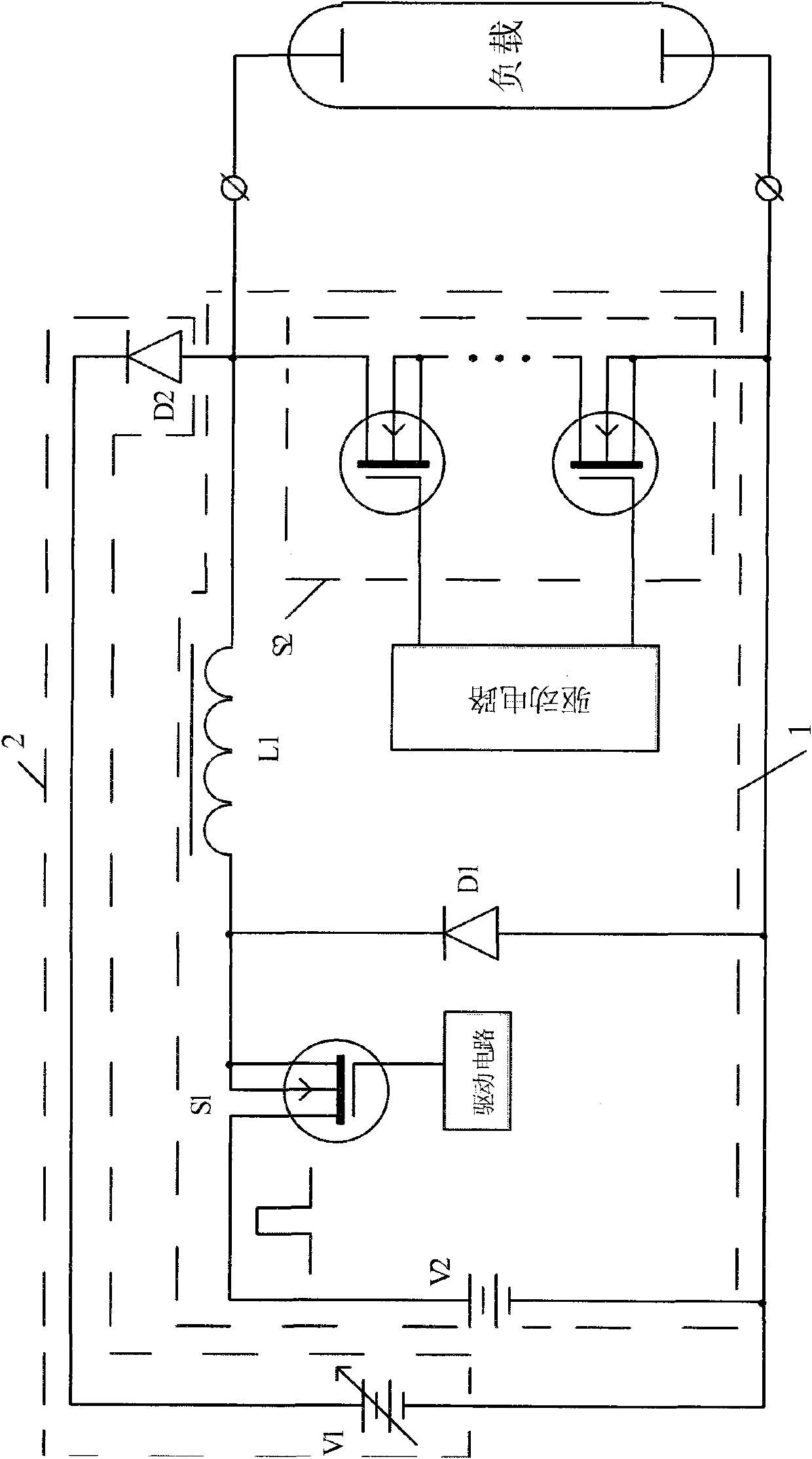

[0008] A microsecond-level high-power pulse current source for inductive energy storage, including an inductive charging circuit 1, an inductive discharging circuit and a clamping circuit 2. The inductive charging circuit 1 is a series connection composed of an excitation power supply V2, an inductance L and a switch tube. loop, the excitation power supply V2 injects magnetic field energy into the inductor L. The inductance discharge circuit is a series loop composed of a load, a freewheeling diode D1 and an inductance L, and the clamp circuit 2 is connected across the inductance charging circuit 1, such as figure 1 shown. The switch tube includes a field effect transistor S1, and a field effect transistor S2 composed of a plurality of field effect transistors connected in series. In the present invention, the described field effect transistor S2 is composed of 3 to 5 field effect transistors connected in series, The excitation power supply V2, the switch tube S1, the inducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com