Nickel-based catalyst for preparing isopropyl alcohol by acetone hydrogenation and application thereof

A technology of catalyst and isopropanol, which is applied in the field of catalyst for preparing isopropanol and its preparation, can solve problems such as unsatisfactory use of the catalyst, and achieve the effects of long service life, low content of metal active components, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using the equal volume impregnation method, according to the water absorption rate of the alumina carrier (produced by Beijing Research Institute of Chemical Industry), the required amount of nickel nitrate, ammonium molybdate and zinc nitrate were dissolved in deionized water to make the volume and the water absorption of the alumina carrier In the same solution, the alumina carrier is impregnated in the solution, dried, calcined, and reduced. Catalyst A-1 containing 10% Ni, 1.0% Mo and 1.0% Zn was made, and the specific surface area and pore volume of the catalyst were measured, which were 174m 2 / g, the pore volume is 0.39m 3 / g.

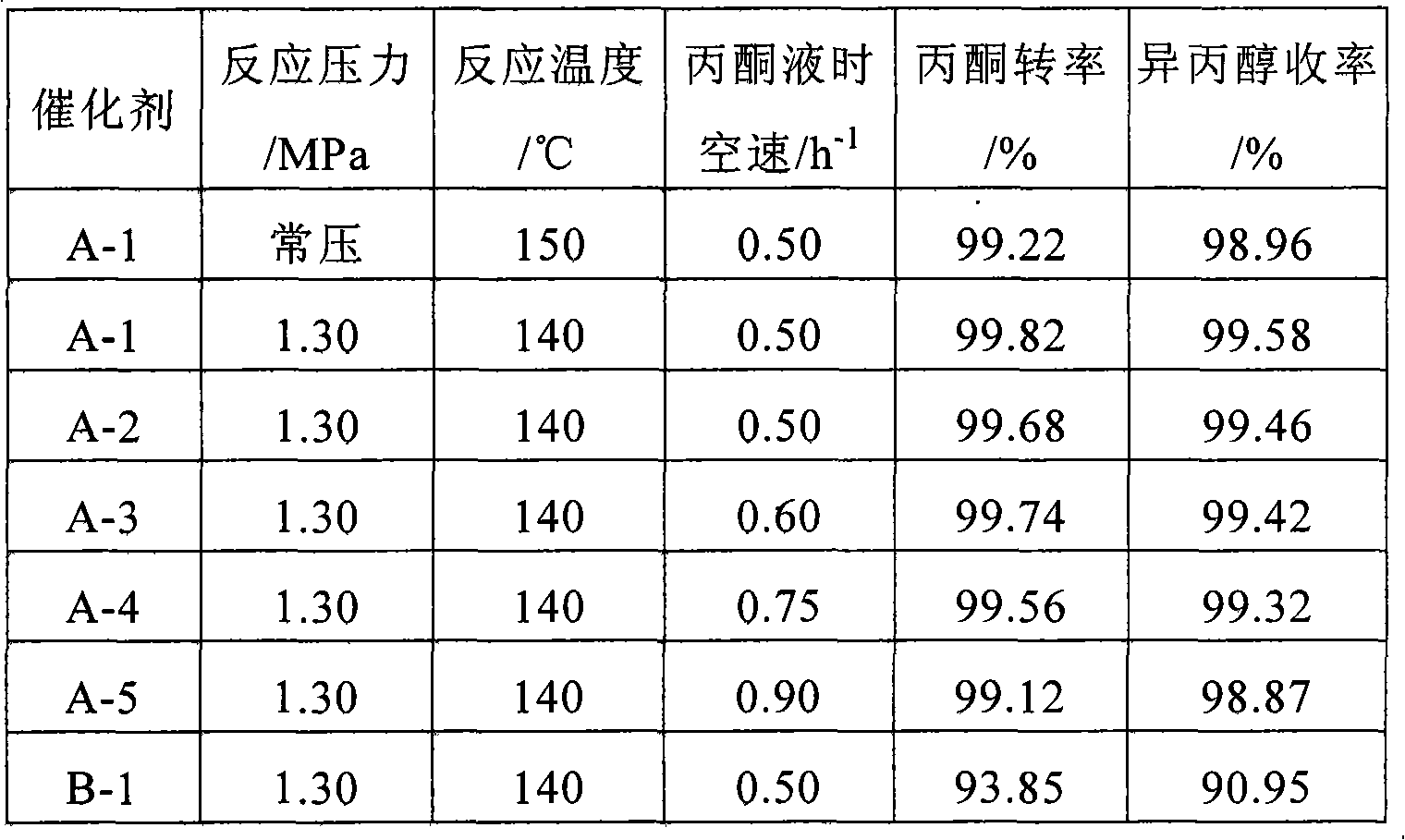

[0026] Put catalyst A-1 into a fixed-bed reactor, feed acetone and hydrogen, at 150°C, normal pressure, acetone liquid hourly space velocity 0.5h -1 The catalytic hydrogenation performance of the catalyst was evaluated. The test results are shown in Table 1.

Embodiment 2

[0028] Put the catalyst A-1 described in Example 1 into a fixed bed reactor, feed acetone and hydrogen, at 140°C, 1.30MPa, acetone liquid hourly space velocity 0.5h -1 The catalytic hydrogenation performance of the catalyst was evaluated as follows, and the test results are shown in Table 1.

Embodiment 3

[0030] Prepare catalyst according to the catalyst preparation method of Example 1, the difference is that the catalyst made contains 12% Ni, 0.5% Mo and 0.5% Zn, is denoted as catalyst A-2, measures the specific surface area and pore volume of catalyst, is respectively 142m 2 / g, the pore volume is 0.32m 3 / g.

[0031] Put the catalyst A-2 into the fixed bed reactor, feed acetone and hydrogen, at 140°C, 1.30MPa, acetone liquid hourly space velocity 0.5h -1 The catalytic hydrogenation performance of the catalyst was evaluated. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com