Method for preparation of isopropanol through acetone hydrogenation

A technology for the preparation of isopropanol and hydrogen, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem of low selectivity of isopropanol, achieve selectivity improvement, and increase the content of metal active components Low, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Acidification treatment method of silica carrier: Add 100g of silica to 2L of 0.5mol / l hydrochloric acid, treat at 80°C for 2 hours, then filter, then treat twice as above, and finally at 100°C Dry in an oven for 24 hours to obtain an acidified silica carrier. After ammonia temperature programmed desorption measurement, the amount of acid contained in the carrier is 0.05×10 -3 mol / g.

[0018] Weigh 30g of acidified silica and put it into 70ml of nickel nitrate solution with a weight fraction of 65% for immersion for 3 hours, then dry it in an oven at 120°C for 24 hours, bake it at 300°C for 6 hours, and finally pass 1,1, 3,3-Tetramethyldisilazane was treated at 160 °C.

[0019] The prepared catalyst has a nickel content of 30% and an organic silicon content of 2%, which is denoted as A-1.

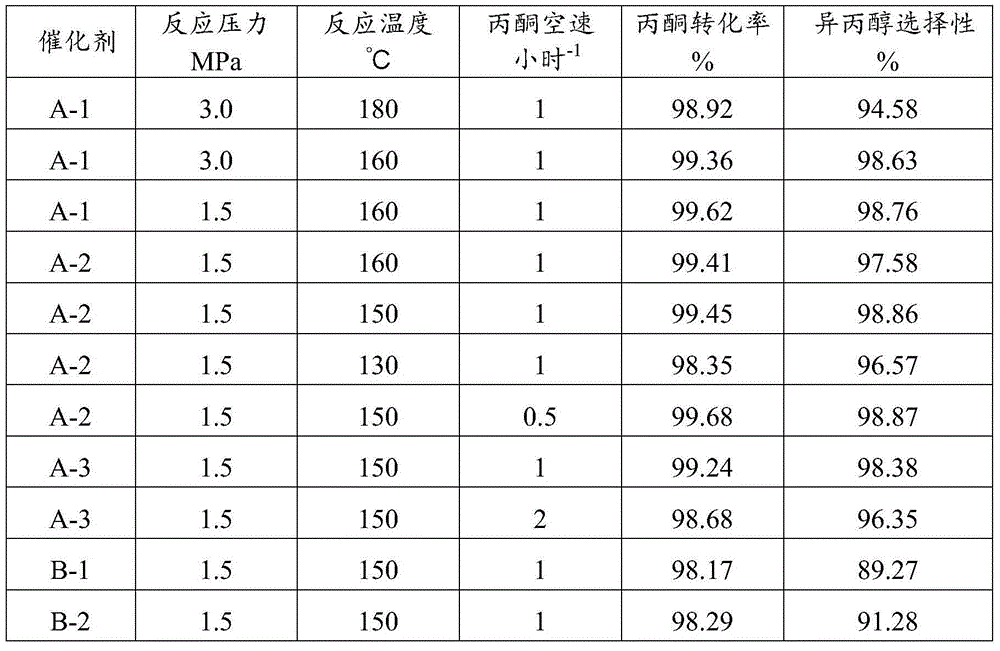

[0020] Put catalyst A-1 into a fixed-bed reactor, pass through acetone and hydrogen, at 180°C, 3.0MPa, acetone space velocity for 1 hour -1 The catalytic hydrogenation performanc...

Embodiment 2

[0022] Put the catalyst A-1 described in [Example 1] into a fixed-bed reactor, feed acetone and hydrogen, at 160°C, 3.0MPa, and acetone space velocity for 1 hour -1 The catalytic hydrogenation performance of the catalyst was evaluated. The test results are shown in Table 1.

Embodiment 3

[0024] Put the catalyst A-1 described in [Example 1] into a fixed-bed reactor, feed acetone and hydrogen, at 160°C, 1.5MPa, acetone space velocity for 1 hour -1 The catalytic hydrogenation performance of the catalyst was evaluated. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com